In the solar cell sector, stringing and tabbing applications involve several factors, such as the need to lower energy costs and enhance the general productivity. Furthermore, the solder joints have to be robust and dependable.

To look into this issue, Ambrell provides induction heating solutions that can be easily combined into the stringing and tabbing machine to achieve improved quality, more repeatable electrical joints, and faster soldering with minimum heat damage to adjacent solar cell substrates.

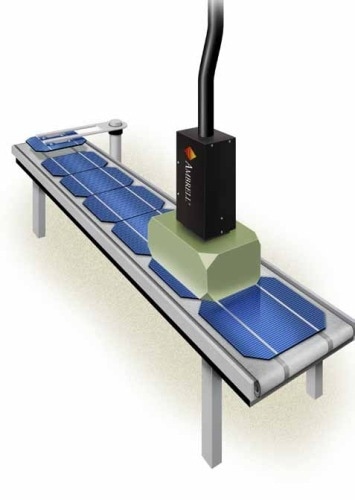

Figure 1. Solar cells

Induction heating generates heat within the tab or string without really heating the adjacent solar cell substrates.

This results in accurate soldering with minimum heat loss, lower energy use, and reduced material damage in comparison to other heating methods. Furthermore, induction heating is fairly fast and solder joints can be finished in a few seconds.

With the assistance of Ambrell’s induction heating solutions, solar cell manufacturers and machine builders can realize higher production volumes, excellent quality, and lower energy costs.

Figure 2. Optimizing solar cell assembly with induction heating

Tabbing Solder Pen

Strip-to-strip power collection interconnects can currently be soldered rapidly and uniformly by using Ambrell EASYHEAT 1 kW power supply and tabbing solder pen. Furthermore, extra soldering is not required for pre-tinned strips.

Induction heats up from within the strip and guarantees better quality solder joints repeatedly. The Solder Pen can be either placed manually or integrated with robotics.

During heating, cooling, and on-demand heating, the solder pen applies a light pressure without causing damage to the product, which is usually the issue with hot irons.

Benefits

Ambrell’s EASYHEAT induction heating systems deliver a precise and reliable solution for soldering applications in stringing and tabbing machines.

Figure 3. EASYHEAT

Along with a clean source of heat, EASYHEAT induction heating systems are ideal for non-contact and repeatable soldering in solar cell assembly. Induction heating systems provide the following advantages:

- Ambrell’s induction heating solutions offer excellent power control and are ideal for soldering applications

- Comprises of a front panel programmable controller that outlines about four different heating profiles, each with up to five time/power steps

- Movable work head can be positioned about 6 m from the power supply

- Fully automated with robot mounted work head, or can be operated manually

- Easily integrated heat source for soldering

- Advanced frequency tuning for precise and repeatable heating

- Provided in five different languages for the operator

- CE compliant

- Includes optional eView software for joint-by-joint logging of heat data

Customer Services and Solutions

Ambrell offers custom service and solutions and has a group of induction heating experts who work meticulously with customers to create a tailored induction heating soldering solution to match a particular solar cell stringing and tabbing machine.

So as to ensure best results, the application is assessed earlier and then the modern induction heating systems are applied to the process.

The company’s service department offers preventive maintenance and emergency support services, so as to ensure that induction heating systems continue to function reliably and steadily for numerous days.

This information has been sourced, reviewed and adapted from materials provided by Ambrell Induction Heating Solutions.

For more information on this source, please visit Ambrell Induction Heating Solutions.