Environmental authorities and water suppliers’ laboratories perform water quality control and environmental monitoring, where the measurement of grease content in wastewater is a vital parameter.

The analytical method is aimed at rapid, selective, and reliable determination of grease content (mg) on dried filters after the filtration of wastewater.

Advantages of NMR

Grease content on filters is usually determined using solvent extraction methods, but these techniques need skilled operators and the use of hazardous solvents, and can be time consuming.

By contrast:

- NMR eliminates the need for solvents, which are dangerous to use and in its disposal

- NMR is a bulk measurement method that selectively determines all the fat and oil present in the sample, irrespective of the distribution of the grease on the filter

- Using a few gravimetrically prepared samples, a linear calibration is instantly produced

- Different compositions of oil and fat can be rapidly measured with the NMR technique

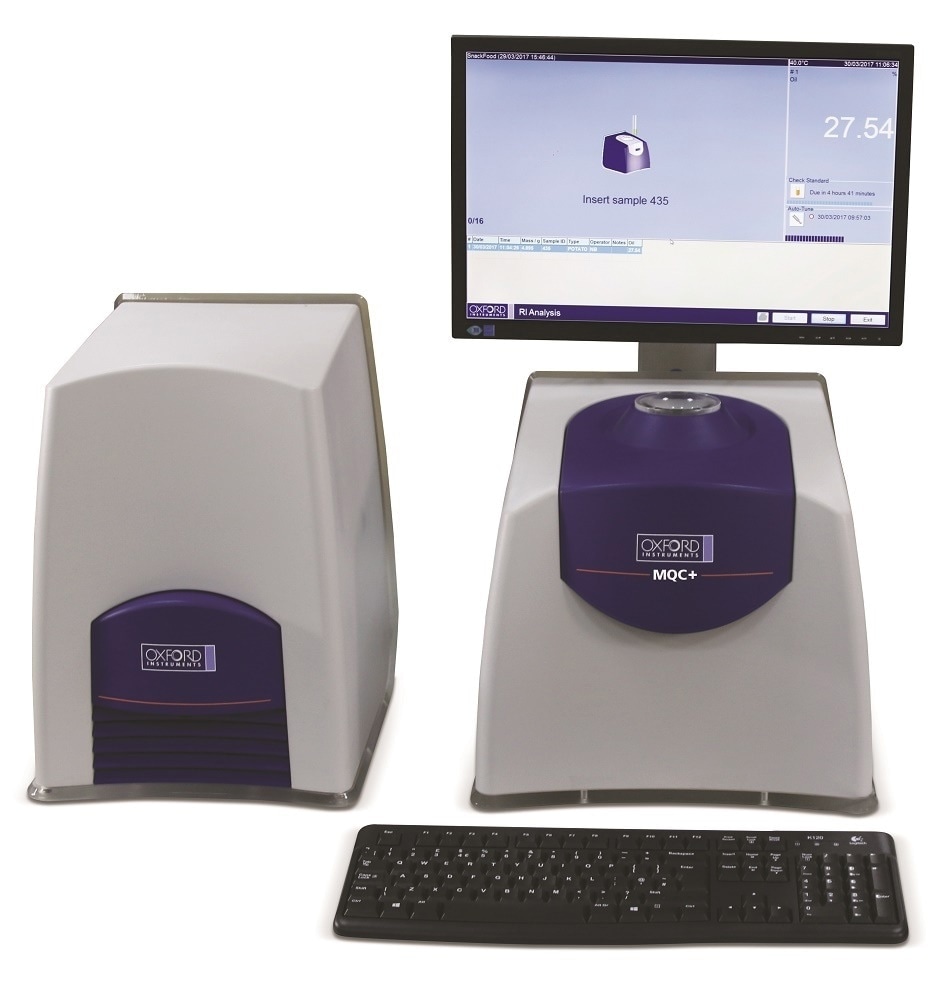

The MQC+ benchtop Nuclear Magnetic Resonance (NMR) analyzer offers an alternative method to extensive wet-chemistry techniques. This instrument is simple to calibrate, fast and easy to perform, and needs minimal sample preparation, thus making it perfect for non-specialist laboratory personnel.

Method

Benchtop NMR is capable of detecting the signal from fat and oil on one, single filter sheet following the initial NMR signals from the solids and complete decay of any residual moisture. The remaining signal intensity correlates with the mass of fat, oil, and grease (FOG) present in the sample.

Calibration

As NMR calibrations are invariably linear, the analyzer can be calibrated using just two reference standards. It is, however, recommended to calibrate the instrument using at least six standard samples with a known fat/oil content, uniformly spread over the range of interest. Before the NMR measurement, the samples should be oven dried.

To prepare the calibration standards, 100 mg of the preferred composition of fat, oil, or grease (mineral oil, animal fat, edible oil, engine lubricant, and so on) is added to 100 ml of petroleum ether. Aliquots are then added to clean filter sheets. Post drying, the reference grease content (mg) of each standard is determined using a precision analytical balance to two decimal places (±0.01 mg).

Measurements

For analysis, a sample is prepared by folding and placing a dried filter sheet containing filtration residuals into a small glass vial. This sample is then temperature conditioned at 40 °C in a dry block for a minimum of 20 minutes before measuring with the MQC+ analyzer. For a single sample, it takes 5 minutes for the total measurement time, excluding the time needed for sample conditioning.

Results

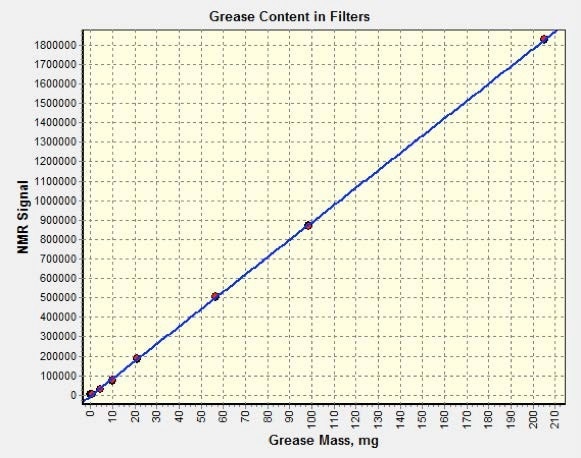

Shown in Figure 1 is a calibration achieved by determining a set of calibration standards against the mass of oil/grease.

Figure 1. NMR calibration generated for a set of standards prepared using the gravimetric data for the oil/fat mixtures. The correlation coefficient and standard deviation are 0.99995 and 0.62 mg, respectively.

In Table 1, the NMR technique is shown to be more accurate than the Soxhlet extraction method when compared against the reference grease content values ascertained by gravimetric analysis.

Table 1. Soxhlet extraction and NMR results for grease content from the calibration standards

| Sample ID |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

Reference grease

content measured

gravimetrically m0, mg |

0.6 |

0.8 |

0.8 |

4.5 |

10.0 |

21.3 |

59.4 |

98.4 |

205.0 |

Grease content

determined by

extraction method

m1, mg |

0.3 |

0.6 |

3.4 |

5.3 |

8.4 |

20.1 |

54.8 |

94.5 |

193.3 |

Grease content

measured by

NMR method m2, mg |

0.9 |

0.9 |

1.0 |

3.7 |

8.9 |

21.2 |

56.9 |

97.7 |

205.4 |

Difference

|m0-m1|, mg |

0.3 |

0.2 |

2.6 |

0.8 |

1.6 |

1.2 |

4.6 |

3.9 |

11.7 |

Difference

|m0-m2|, mg |

0.3 |

0.1 |

0.2 |

0.8 |

1.1 |

0.1 |

2.5 |

0.7 |

0.4 |

Table 2 demonstrates the repeatability of the NMR technique using one low and one more typical concentration.

Table 2. Results of NMR repeatability test

| Grease Sample, mg |

Repeat Measurements: Grease content by NMR, mg |

Mean, mg |

Standard deviation, mg |

| 1.2 |

1.24 |

1.24 |

1.02 |

1.34 |

1.43 |

1.27 |

1.14 |

1.27 |

1.13 |

1.21 |

1.29 |

1.23 |

0.11 |

| 31.4 |

31.39 |

31.38 |

31.53 |

31.17 |

31.45 |

31.37 |

31.36 |

31.46 |

31.05 |

31.36 |

31.36 |

31.35 |

0.13 |

Conclusion

- The NMR method is non-destructive, and hence repeat measurements can be made easily

- The sensitivity of Oxford Instruments’ MQC+ allows accurate measurements of oil/grease content on one filter sheet

- Analysis measurements provide good repeatability

- The accuracy of NMR measurement is better than that of the extraction technique

- The single sample measurement is fast (usually 5 minutes).

- Minimal sample preparation is needed, without using dangerous solvents and other media

Complete Package

Oxford Instruments provides the following package that is customized for accurate measurements of the grease content present on filters:

- Oxford Instruments MQC+23 NMR Analyzer:

- Probe for 23 mm diameter vials

- 0.55 Tesla (23.4 MHz) high homogeneity magnet

- Integrated flat-screen display

- Integrated system controller (external PC is not needed)

- MultiQuant software including RI Analysis, RI Calibration, and the EasyCal “Grease on Filters” application

- 23 mm diameter sample vials

- Test/tuning sample

- PTFE sample vial holders

- Method sheet

- User manuals

In addition, one may need:

- A precision balance (two decimal places, ±0.01 mg)

- A dry block heater and aluminum block with holes for sample conditioning at 40 °C

This information has been sourced, reviewed and adapted from materials provided by Oxford Instruments Magnetic Resonance.

For more information on this source, please visit Oxford Instruments Magnetic Resonance.