Toner powder used by laser printers and photocopiers is a hybrid of carbon and a polymer. The actual polymer utilized differs according to producer, while toner formulations differ between producers, and even between machines. Granule size is a key means of differentiating each formulation.

According to Wikipedia, “Originally, the particle size of toners averaged 14–16 micrometers or greater. To improve image resolution, particle size was reduced, eventually reaching about 8–10 micrometers for 600 dots per inch resolution. Toner manufacturers maintain a quality control standard for particle size distribution in order to produce a powder suitable for use in their printers.”

Image Credit: Vision Analytical Inc.

Toner grains are small, with a low quantity of larger beads in occurrence, and are almost spherical. As it is legitimately possible to presuppose universal sphericity, it is enough to implement Equivalent Circular Area as the predominant size measure, alongside Circularity and Smoothness, which yield further characterization.

| |

Measure |

Range of acceptance |

| Applicable measures |

Equivalent Circular Area Diameter |

2 – 500 microns |

| Smoothness |

0 to 1.0 |

| Circularity |

0 to 1.0 |

Image analysis settings encompassed minimum pixel area: 5; maximum pixel area: 50000; binary threshold: 80%; focus rejection parameter: 50; pump speed: 40%; and the option to correct size for diffraction effects was permitted.

Results

Image Credit: Vision Analytical Inc.

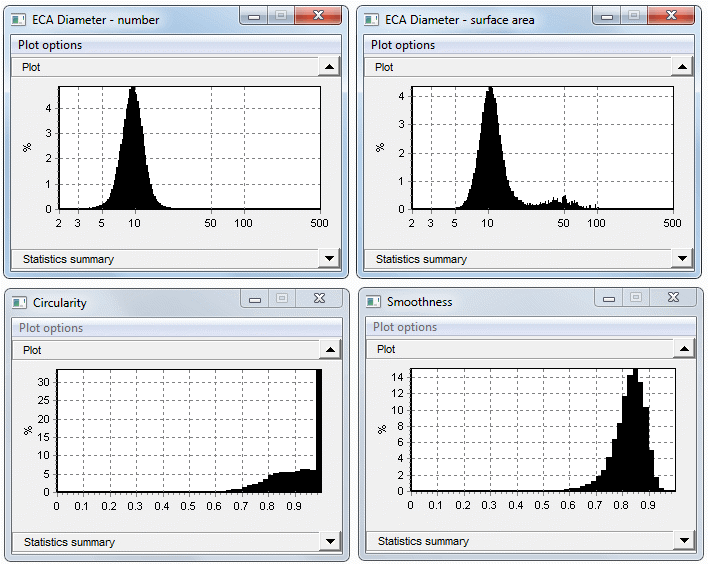

A particle count of 150,000 generates extremely smooth distribution graphs. The ECA histogram is remarkably close to normal, with low skewness. The smallest size observed was 2 microns, while the center measured around 10 microns.

Presented below are the “small data window” graphs for ECA (number and surface area), Circularity, and Smoothness. The large beads are numerically insufficient compared to the toner grains to appear in the unweighted distribution. However, they can be observed in the surface area-weighted graph, because they represent a noticeable amount of the aggregate surface area. The spike in Circularity at 1 is a reflection of the large beads and the majority of the small grains.

Image Credit: Vision Analytical Inc.

This information has been sourced, reviewed and adapted from materials provided by Vision Analytical Inc.

For more information on this source, please visit Vision Analytical Inc.