Abrasive powders are utilized in a number of commonplace functions. They comprise the particles utilized for polishing teeth, constitute abrasive polishes to make high end automotive finishes shine, and even form the sandpaper a carpenter implements on a daily basis. Each of these powders are engineered to remove material, with some more aggressive in removal than others. Typically, the abrasiveness of particles is known as the “grit” of the powder.

Predictably, the more aggressive the grit, the more efficiently the material is removed. However, the powder's grit is not only determined by the size of the particles, but also its shape properties. A low grit, corresponding to a more robust removal, has larger particles. Nevertheless, if these larger particles were all smooth and round, the removal effectiveness would be weak. Consequently, both size and smoothness are key factors in the performance of abrasive powders.

This study examines multiple abrasive powders, demonstrating not only how these powders diverge in terms of size for the various grit classifications, but also how they correlate in terms of smoothness. As will be shown, determining abrasive consistency is not undertaken solely by size; the powders' smoothness is also a crucial factor.

| |

Measure |

Range of acceptance |

| Applicable Measures |

Equivalent Circular Area Diameter |

3 – 500 microns |

| Smoothness |

0 – 1.0 |

Procedures and Results

Multiple abrasive powder samples were examined. For this study, three alternative abrasive powders were utilized, each representing a separate “grit.” The producers of these abrasive powders typically implement a size-only calibration to ascertain the quality of their abrasive powders, prior to dispatching them to their ultimate usage; polish, and in most instances, sandpapers for various functions.

Particle-size-only apparatus will measure dimensions as if the particles are spherical, and will not measure shape properties. This might be satisfactory for certain raw materials, but where the smoothness of the particles is in direct accordance with their performance, this is insufficient.

The Particle Insight is capable of analyzing thousands of particles in a matter of minutes, and can yield results totaling 30 size and shape measurements. For this report, the Particle Insight executed comprehensive statistical analysis of the smoothness of the particles, and enabled the operator to observe any singular particle that might have been out of specification.

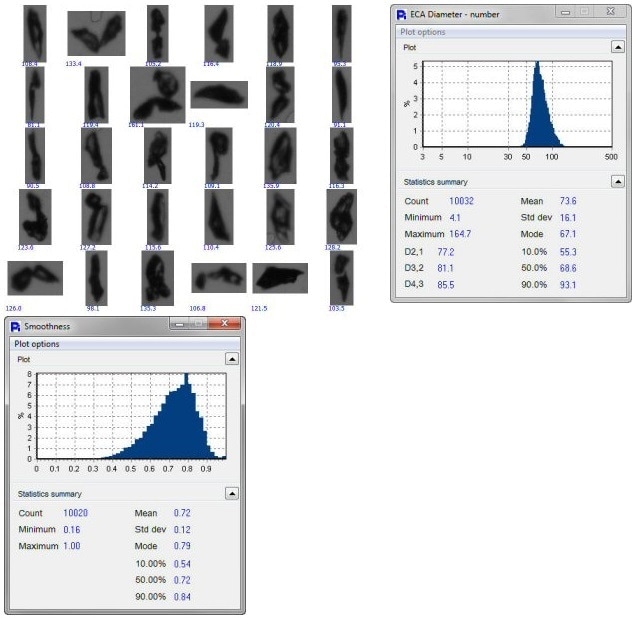

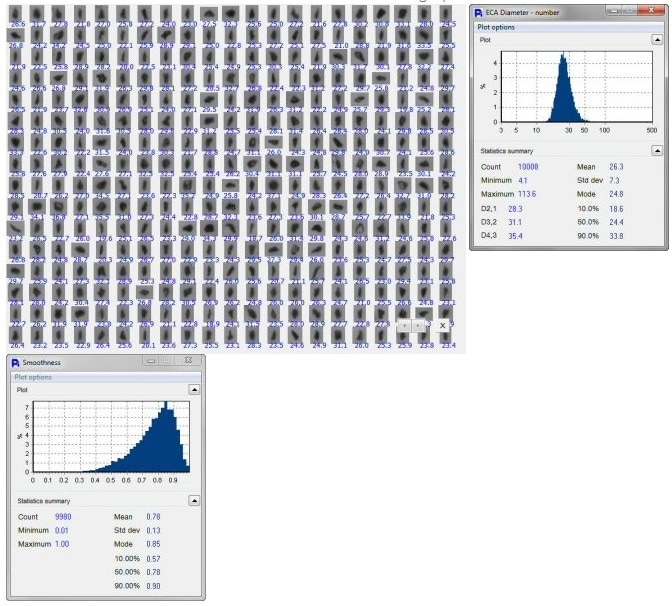

Particle Images and Data

Image Credit: Vision Analytical Inc.

Abrasive powders of certain grit dimensions record an average diameter of 73.6 microns. However, this number only represents a rough size calculation if the particles are not round. Surface smoothness yields a more satisfactory means of characterizing of the particles. Smoothness of each of the measured particles is exhibited as a statistical histogram here.

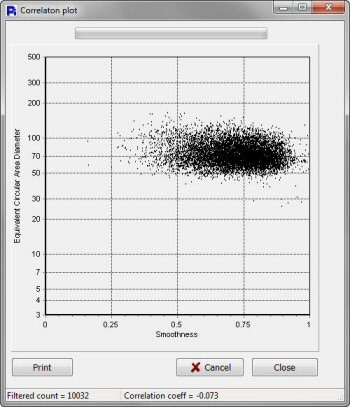

The Particle Insight permits the correlation of any two size/shape measurements. A scatter graph of each of these abrasive particles, plotted according to size and smoothness, is presented here. The correlation plot demonstrates that size and smoothness are almost always independent of each other.

Image Credit: Vision Analytical Inc.

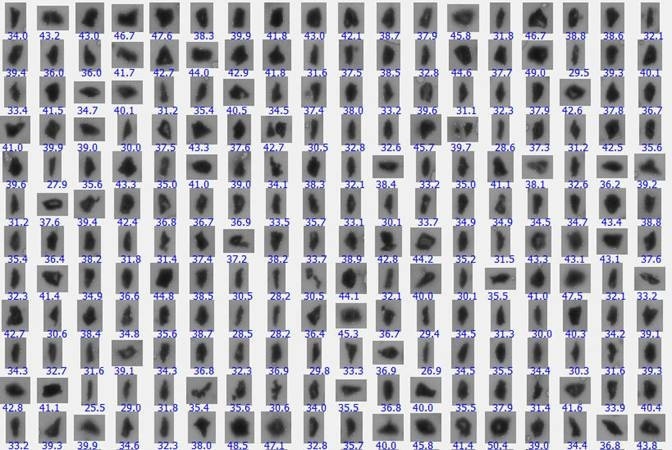

Image Credit: Vision Analytical Inc.

Image Credit: Vision Analytical Inc.

Abrasive powders of a higher grit number, or finer particles, are presented here. The average size of these particles are smaller, 30.4 microns, but the average smoothness of 0.81 (1 representing perfect smoothness) is roughly the same as the prior case.

Image Credit: Vision Analytical Inc.

Image Credit: Vision Analytical Inc.

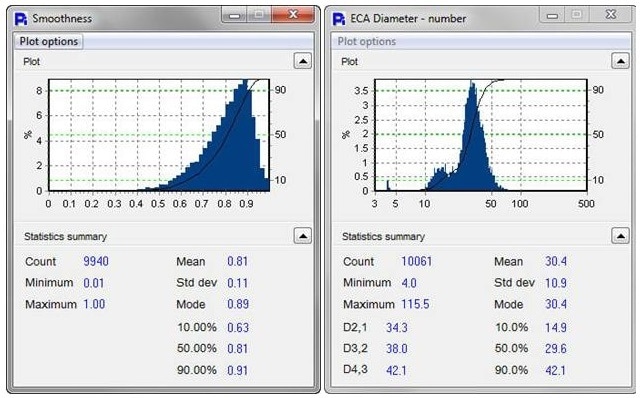

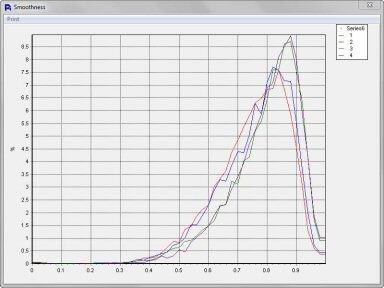

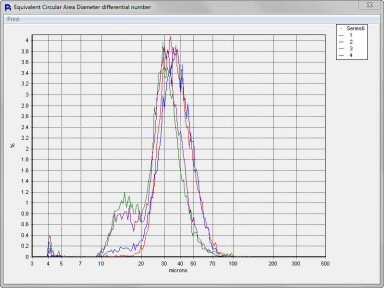

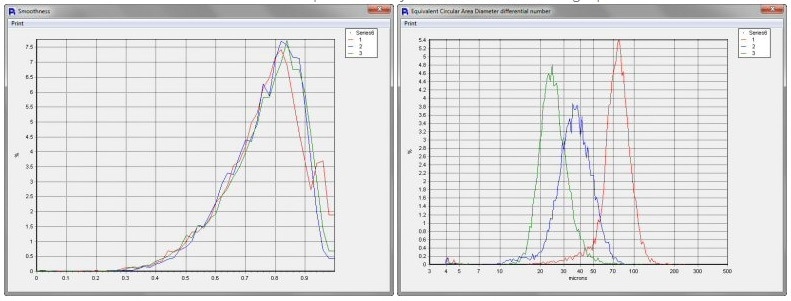

Moreover, the Particle Insight can overlay various samples on the same plot to enable differentiation of size and shape measurements. Some samples overlay in size adequately, but possess a high ratio of fine particles, as shown here. Nevertheless, the fine particles do not affect the general smoothness; the smoothness of these particles is comparable to that of the larger particles.

Image Credit: Vision Analytical Inc.

Even finer particles with a size of around 26.3 microns are presented here. As before, it can be seen that, while the size of the particles decreases in inverse proportion to the grit number, the smoothness of the abrasive particles is still comparable with that of the other grit powders.

Image Credit: Vision Analytical Inc.

Analysis of the three separate grits of abrasive powders yielded three different particle sizes, as would be expected. However, this study reveals that, irrespective of the size or grit of the abrasive powders, their smoothness remained remarkably homogeneous. This indicates that the grinding processes employed by the manufacturers of these abrasive powders is adequately regulated. This smoothness constancy, irrespective of size, is an important way of ensuring performance consistency, whatever the abrasive particles' end use.

Another identifiable feature of the Particle Insight is that, because it performs a direct measurement technique, operating on a counting or single-particle basis, if there are any large, undesirable particles, these can easily be identified. This identification is executed using the number based distribution and data for any individual particle, but also by observing the thumbnails for each out-of-specification particle. After all, no consumer would want to polish their car with a product containing even one large unwanted particle.

This information has been sourced, reviewed and adapted from materials provided by Vision Analytical Inc.

For more information on this source, please visit Vision Analytical Inc.