This study focuses on the characteristics of specific cellulose fibers deriving from natural sources. They are manufactured as thickening agents, which appear in a number of domestic consumer commodities, including cosmetics, shampoos, and many more. Length, breadth (thickness) and curl significantly influence the viscosity of the final commodity.

| |

Measure |

Range of acceptance |

| Applicable Measures |

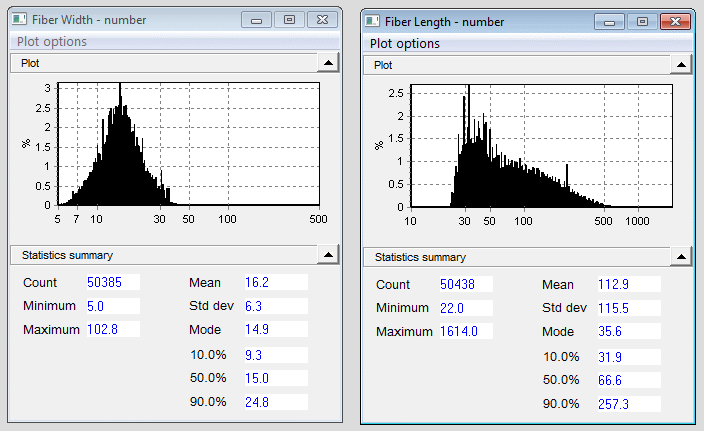

Fiber Width |

5 – 500 microns |

| Fiber Length |

10 – 1000 microns |

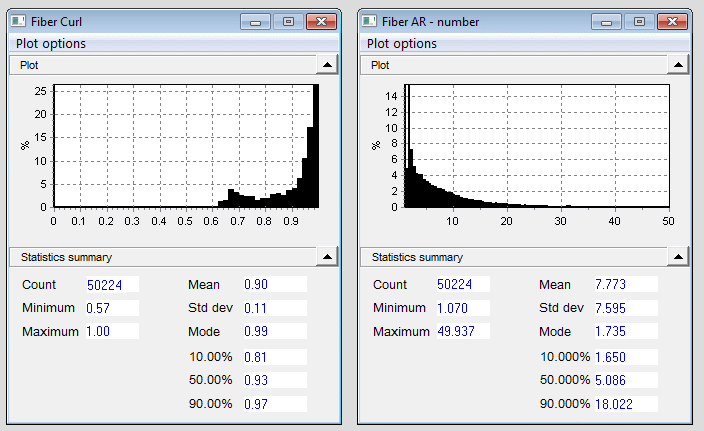

| Fiber Aspect Ratio |

1.0 – 50.0 |

| Fiber Curl |

0 – 1.00 |

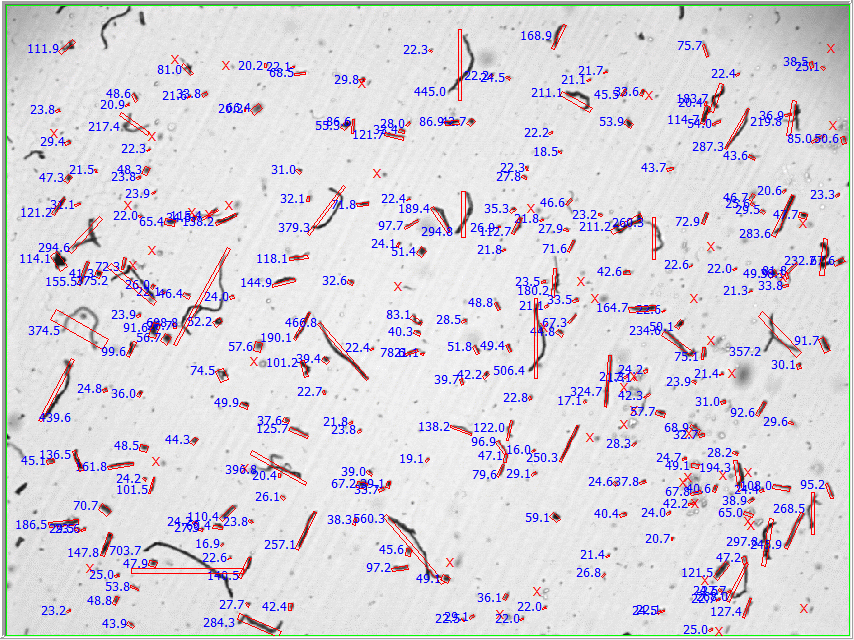

Typical Image

Notes

Fibers of this category are first suspended in propanol, which prevents rapid dissolution, and are subsequently intermixed thoroughly. As longer fibers typically arrange themselves according to the orientation of flow, the examination of lengths with greater extension than the width of the flow cell is possible. The above image exhibits Fiber Length values. The fiber shape model aligns the long, narrow fibers and records length, width, and aspect ratio of the aligned rectangle.

Results

Fiber Width displays symmetry around the average (16 microns). Fiber Length displays an acute increase and subsequently a straight decrease to 500 microns. This decrease is nearly linear (on the log scale). Fiber length distributions do not usually adhere to the typical particle size distribution shapes.

Curl is actually an index of straightness, represented in numerical terms. 1.0 represents perfect straightness, while lower values correspond to a more curled shape. Aspect ratio, the proportion of length to width, displays an average value of 7.7. The largest aspect ratio observed was around 50.

This information has been sourced, reviewed and adapted from materials provided by Vision Analytical Inc.

For more information on this source, please visit Vision Analytical Inc.