High Performance Liquid Chromatography is a separation technique employed by analytical chemists for the separation, identification, and qualification of multiple compounds in a solution. The majority of conventional analytical HPLC packing materials embody a mean diameter of between 2 and 30 microns. The particle size of the packing material is typically calculated with techniques which assume homogeneous particle roundness. However, this is not always appropriate, as fine and irregularly shaped particles often comprise a proportion of the final product.

When particle size reaches lower levels, the increased impact of fine and irregularly shaped particles necessitates extra control over the incoming silica material quality. Particle shape variation can have a direct impact on reproducible performance. Therefore, a means of quantifying the fine and non-spherical particles is required.

| |

Measure |

Range of Acceptance |

| Applicable Measures |

Feret Width |

3 – 100 microns |

| Feret Length |

3 – 100 microns |

| Feret Aspect Ratio |

1.0 – 30.0 microns |

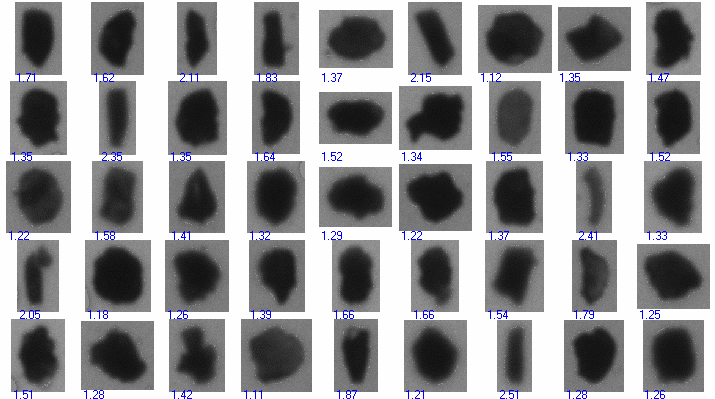

Typical Thumbnail Page

Randomized thumbnail images of the alumina sample, deriving from the 10,000 that were taken in just over one minute, are displayed here. The value beneath every thumbnail describes the Feret Aspect Ratio of each particle.

Procedures and Results

Established sampling of the incoming materials was undertaken to guarantee a uniform sub-sample. The sample was subsequently suspended in water and examined. Following this examination, and an analysis of each particle thumbnail image, it became clear that this alumina sample embodied two distinctive shape populations.

One was rod-shaped, while the other was characterized by an aspect ratio approaching unity, although the particles were non-spherical. If the sample had been examined utilizing a sizing methodology which assumed uniform particle roundness, there would be no differentiation of these rod-shaped and non-regular particles.

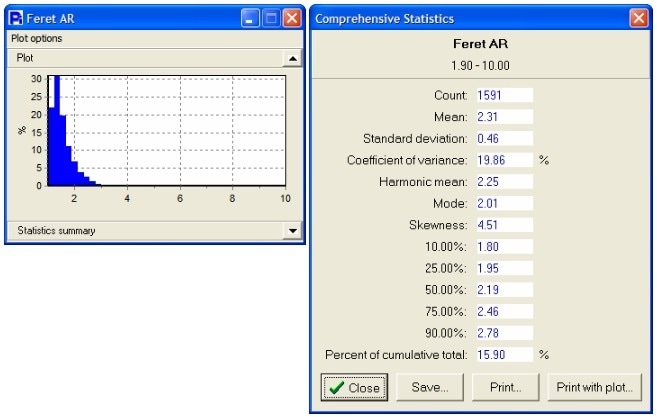

In generating a methodology for this sample, particles embodying an aspect ratio of more than 1.9 were categorized as rod-shaped, and thus likelier to have a negative effect on column packing efficiency. That aspect ratio value limit was obtained from sample lots that manifested the issues reported above, as well as those that did not.

As demonstrated by the histogram and statistical data, the proportion of rod-shaped particles in the column packing material represented 15.90% of the aggregate distribution. This, when compared with the historical lot of adequate material, was shown to be inordinate for this particular column application.

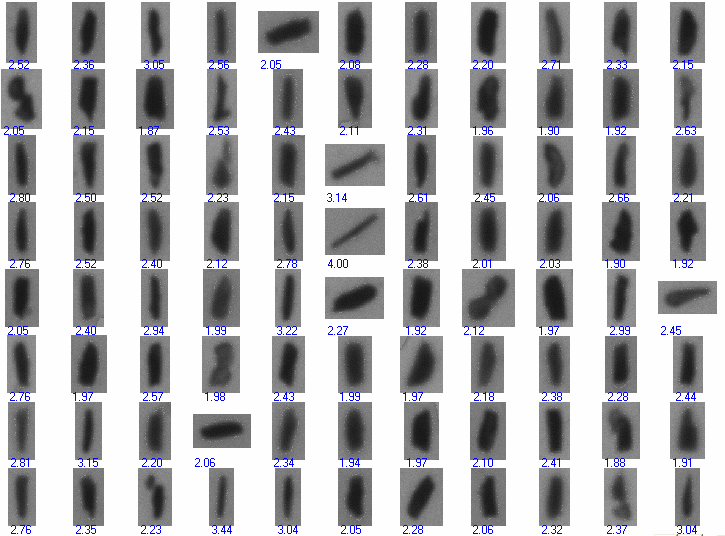

An examination of the thumbnails containing solely those particles with a Feret Aspect Ratio of more than 1.9 yields a more satisfactory representation of these particles' actual appearance.

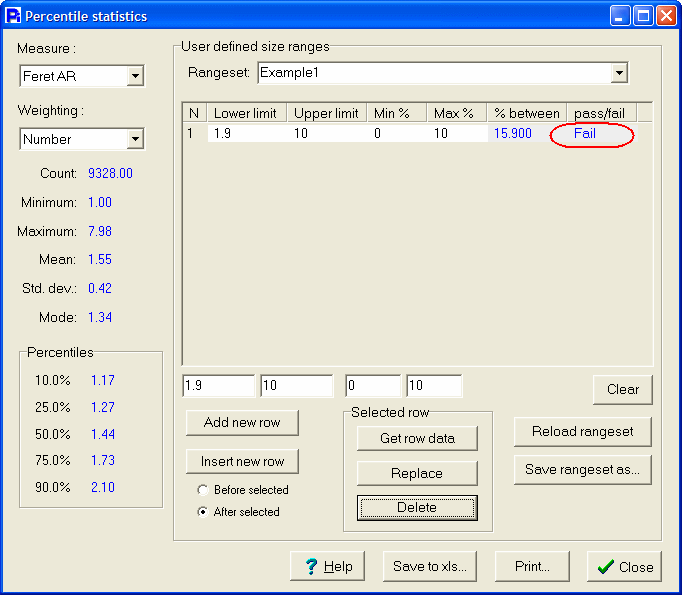

With the establishment of a methodology to ensure that the Feret Aspect Ratio of incoming alumina packing material contained less than 10% rod-shaped particles, the end-user can generate a straightforward process control indicator using the Particle Insight.

Implementing the Percentile Statistics component, incoming quality control can simply and efficiently establish the quantity of material which has passed or failed management selected criteria.

Conclusions

With its Dynamic Image Analysis method, the Particle Insight can help minimize costs by locating HPLC packing material irregularities before the column manufacturing process. The producer retains responsibility for determining the admissible proportion of non-spherical particles for incoming materials. After the manufacturer has established incoming quality control criteria, the Particle Insight can be implemented as a pass/fail assessment instrument, which can intuit the proportion of spherical to non-spherical particles.

A quick and efficient resolution of this potential problem enhances productivity and increases the consistency of HPLC column quality and performance.

This information has been sourced, reviewed and adapted from materials provided by Vision Analytical Inc.

For more information on this source, please visit Vision Analytical Inc.