In this interview, AZoM talks to Erica Lawrence, Product Manager at Instron, about how universal testing machines are matching the requirements of product development.

What are the benefits of using a universal testing machine?

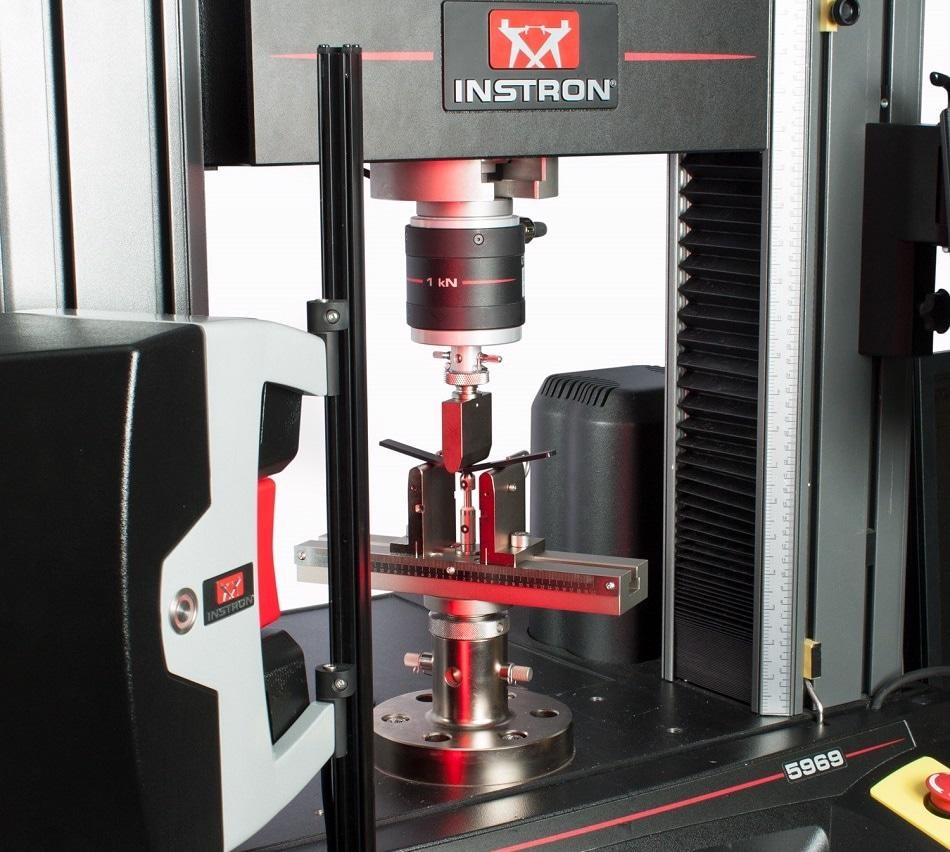

The biggest benefit is right in the name—these systems are universal. A single machine is able to test everything from the peel strength of tape to the tensile strength of rebar, simply by changing out accessories. When Instron’s founders created the first electromechanical universal testing machine in the 1940’s, they were only trying to find fibers strong enough to substitute for silk when making parachutes. Seventy years later we’ve gone from limited systems with simple chart recorders to the powerful 5900 series with Bluehill Universal software. Today’s universal testing systems let us test virtually any type of material in the world and report their mechanical properties with unbelievable accuracy.

What are you seeing as some of the trends in the materials testing industry and how has Instron adapted?

In mechanical testing we are seeing more and more customers wanting to connect their lab equipment either to Lab Information Management Systems (LIMS) or to other hardware devices. Instron has made deliberate efforts to make this easier than ever for our customers. Because each LIMS and every device is different, we’ve had to build this flexibility directly into our products. When we released our latest testing software, Bluehill® Universal, we added new export capability so that the exports can be completely customized for everything from file format to delimitators. For hardware, we have long-supported digital I/O channels for triggering and connecting to external devices. This is becoming an increasingly popular feature as customers connect everything from scales, solenoids, and external measuring devices to their Instron.

What are some of the most important aspects companies should consider when purchasing a testing system?

Buying a testing system is an investment that can last for decades. These machines often become a critical part of a lab’s day-to-day operations, so companies need to make sure that the system they choose can keep up with their needs and expectations throughout its lifetime. At Instron we have a field-based service organization with technicians located all around the world. The average age of the equipment we service is almost 20 years old, and a big reason for this is because our service technicians are local to our customers and easily available to help them protect their investments. You’ll also want to ensure that your system is able to comply not only with the tests you perform currently, but also with your future testing needs wherever possible. Instron is focused on making our 5900 series systems as adaptable as possible to help customers ensure that their labs are as futureproof as they can be.

How can customers ensure flexibility in a system for that length of time?

One of the best ways to breathe new life into a system is to upgrade its accessories and software. The hardware of the frame itself can last for decades, but Instron operators see a lot of great benefits when they choose to replace their older electronics with our new 5900 controllers. Upgrading this controller gives users access to countless new improvements—new software and strain products being two of the most popular options. For example, labs that once used multiple clip-on extensometers can now take advantage of the Advanced Video Extensometer (AVE) 2, meaning that they now have a single device to handle all of their strain needs. The newer electronics and accessories can be combined with the latest software, which makes a 20-year-old system feel brand new.

Advanced Video Extensometer (AVE) 2

What role does software play in materials testing equipment selection?

Software has become the main point of operator interaction on a universal testing machine. Software controls everything from specimen dimensions to test control parameters to results exporting. We encourage customers to try demos of Bluehill Universal, which really allows the user experience to speak for itself. Our development team works hard to strike a balance between making software powerful enough to perform even the most complex testing and yet simple enough for an operator of any experience level to navigate the platform successfully. Because of this we are continuously upgrading our software based on customer feedback. One of the latest features we’ve added is enhanced security with Active Directory support, which allows lab managers to control user permissions for all of their test operators.

Bluehill Universal Material Testing Software

How have companies adapted to new testing and product development requirements?

More and more we see companies using mechanical testing to try and simulate real-world use of their materials and products. It’s not always enough to simply characterize the tensile modulus and strength of a material to understand how it will behave in its intended application. For example, let’s say you need to test a composite that is going to be used in an aerospace application and be subjected to extreme temperatures. The best way to ensure that the material performs the way we need it to is to put it inside an environmental chamber and test it under those same extreme conditions. If your company produces twist-and-pull childproof bottle caps, a torsion-add on can help simulate these simultaneous axial and torsional forces in the laboratory.

Torsion-Add On

How does Instron keep up to date with what’s required in the industry?

The most important thing we do is to get out and talk to customers. We find that the best products come from focusing on their needs, and there’s no better way to do this than to visit labs around the world and see how people interact with our equipment. We also make sure to stay up to date on testing standards. You can always find Instron representatives on ASTM and ISO committees. All of the products I’ve mentioned have been developed as a result of these customer interactions and industry insights.

About Erica Lawrence

Erica Lawrence is a Product Manager at Instron for electromechanical testing systems. Erica began her career at Instron in the applications engineering group, testing and providing customers with recommendations for equipment needs. Prior to working at Instron, Erica worked in the construction industry doing failure analysis and development of new materials after graduating with a Bachelor of Science in Chemical Engineering from Northeastern University.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.