MTI Instruments has been providing non-contact physical measurement tools for almost 60 years. A leading US company, MTI has a global client base spanning a multitude of industries from transportation and power generation to factory automation and consumer electronics.

What is one of the main issues in the automotive industry right now?

Computational power today is even more important than before.

For instance, an autonomous vehicle that's going to drive itself can ask the cloud, “Should I make a right or a left?” It has to make instant decisions. This is called edge computing. For this, you have to have enough computational ability on board to be able to make important decisions, but you can't have all of the cloud on your computer. It's just not going to happen. So, the industry goes in between, using hybrid clouds that offer enough computational ability.

However, for you to have enough computational ability on-board, you must process information very quickly and very efficiently, and that requires power.

Power is the biggest issue, and finding the right materials to provide it. Some people are actually putting a ratio together of efficiency versus power, because if you want to get to the next level of computing ability so that you can enable more decision making faster, then you have to find the materials or you have to find a way to decrease the power that these computations use.

So, as part of the whole process, there is the issue of finding the materials. Aluminium and titanium carbide wafers, as well as other materials, are being looked at and been studied, and they're making quite a bit of progress. These materials and the substrates are very useful in the whole chain to reduce power.

Image Credit:Shutterstock/Jenson

Where do MTI Instruments fit into this?

MTI instruments can measure these substrates thicknesses and shapes at the front-end process to help in the qualification for their use as well as to ensure no issues down the line. In fact, capacitive technology has been used in taking measurements for these and many other substrate materials.

What is a wafer?

Imagine you’re building skyscrapers in a city, and the city is the wafer. You start with a silicon substrate, for instance, and then you start putting layers of conducted materials on it. You start to build very thin floors in order to have more electrical connectivities between layers, allowing you to build your city, or in reality, your chips.

From start to finish, a wafer can go through the whole semiconductor process in about 45 to 60 days.

At the beginning, a substrate can cost you 10 to 20 dollars, depending on what kind of substrate you are using. But, when you're done, you can get two hundred chips out of the wafers that you can sell for 300 or 400 dollars each.

What role does MTI play in the wafer manufacturing process?

MTI carries out a certain part of the process. We measure the health of these wafers by making thickness measurements and shape measurements.

People are familiar with bow and warp and site flatness, which simply answer questions as to whether the wafer is warped, and if it is, by how much, and whether it is warped by more than X. There is a quantitative aspect to it. If an area of wafer is warped, there may be defects on the chips as a result.

MTI makes those measurements, and our ability to make measurements in more exotic materials becomes important. 25 years ago, we were only using silicon.

But now, they are using germanium for different applications, for example. The variety of materials is wider. All of these materials have different compositions and different properties. For example, germanium is used for night vision goggles for the military, but silicon is used for regular computers. It depends on what we’re doing with the chip.

MTI's ability to measure many substrates, including aluminium and titanium carbide, becomes important. It’s important because it takes the substrate of choice at the moment.

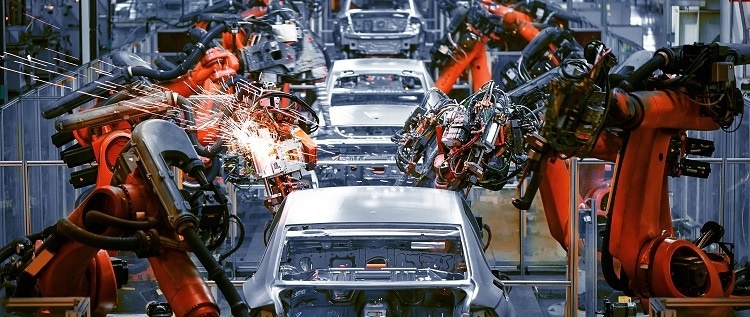

The second aspect of MTI’s involvement is in enabling computing in the automotive industry, especially in regards to artificial intelligence (AI). AI is the area right now where there is the most research is happening. Automotive seems so close, and everybody is rushing to get into this space because they’re putting in a lot of money, and a lot of money brings good development. As a result, they’re finding that they're advancing the AI quickly enough to make cars using it.

At MTI, we feel like we are a part of these trends in motor sectors where larger companies are going through zero defects.

Why is achieving zero defects important and how does MTI help this happen?

If you have a car and there are four times more chips on your regular parts on your electric vehicle than you had in your regular vehicle today, you don't want any defects.

Considering that a computer right now isn’t even that reliable, imagine that you’re driving and you have to reboot. That gives a lot of liability to the car companies. If your car stops in the middle of a busy highway and you get rammed in the back, you’ve got a big loss.

As a result, the automotive sector is petrified of any defects on these semiconductors. So, this is where we at MTI come into play. We are part of the establishment to help the automotive industry and many other industries to get zero defects on chips. We are a small little piece of that big chain, but we're a part of it. We're up in the beginning process.

Image Credit:Shutterstock/PhonlamaiPhoto

What role do you think all of this will play in the future in the automotive industry? Are there any other applications that MTI’s work with wafers can be employed?

The biggest applications at the moment where most money will be spent are in automobiles. Additionally, where AI is being applied, we are producing things that haven’t been done for 30 years. Many technologies are enabling these sorts of collaborations to get new cars that are autonomous. That's number one. But then you'll have all sorts of methods of transportation additional to cars that would also be autonomous.

There are huge applications for AI in medicine, too. Right now, you're looking at machines starting to diagnose diseases, for example in radiology where images are taken. What they’re doing in this area is enabling doctors to see whether you have cancer just by looking at a picture, for instance. They’re able to do this because they have trained for thirty years.

In the same sense, machine learning can actually take pictures. It used to be that AI was only structured data like numbers, but computers weren't really able to recognize the picture. But, now they can because of the way AI is working and including these unstructured data patterns. So, now, we can train a computer to look at scans and determine whether or not the patient has cancer. Computers can learn the difference.

Now, these computers can actually predict these cancer cases. Some computers can predict these cases better than human doctors. So, medical applications will be really interesting.

The energy that’s needed to make these computations is huge. It’s said that to make a neuron network learn the image of a cat, and actually recognize that something is a cat and not a cat, took 400 kilowatts, and it took 12 days.

So we're still at the very beginning of the learning process. However, at IBM, they are actually tasking a neuron network to learn everything it can. This computer is learning everything it can from the Internet about material science, so it can discover new materials that are better for our consumption. So they are actually helping us by doing this.

About George Relan

George Relan, MTI Instruments’ Director of Sales for the Instruments division, joined Mechanical Technology in 2000 and later MTI Instruments in 2013. Mr. Relan is responsible for product sales, marketing and sales strategy. Since joining MTI, he has held numerous positions in both the corporate side and within the MTI Instruments division including Director of Market Strategy and VP of Corporate Development. Previously, Mr. Relan worked for Honeywell International, and General Electric.

Mr. Relan holds an M.B.A. and a B.S. from Rensselaer Polytechnic Institute.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.