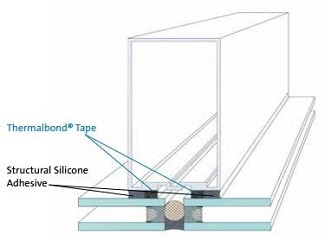

Spacer tape is a key component in structural silicone glazing systems, where it is used to maintain a consistent gap between the glazing panel and the structure, as well as providing a locating surface for the silicone structural sealant. Thermalbond® is the premium structural glazing spacer tape on the market and has been made the industry standard. Architects have put their trust in Thermalbond, the world’s first two-sided spacer tape since it first came onto the market in 1979. Both façade consultants and silicone manufacturers alike recommend Thermalbond as they know it will ensure a correct cure in the silicone it has a proven record of reliability and safety.

Thermalbond was originally developed by Norton Company (now part of Saint-Gobain) and has often been referred to as “Norton Tape” in the past. Thermalbond spacer tapes are vital materials in numerous curtain wall applications, including some of the most recognizable skyscrapers in the world, including One World Trade Center (Freedom Tower) in New York, Liberty Place, One and Two in Philadelphia, NATO headquarters in Brussels, the Marina Bay Sands Resort in Singapore and the Burg Al Arab in Dubai.

Thermalbond® Product Series

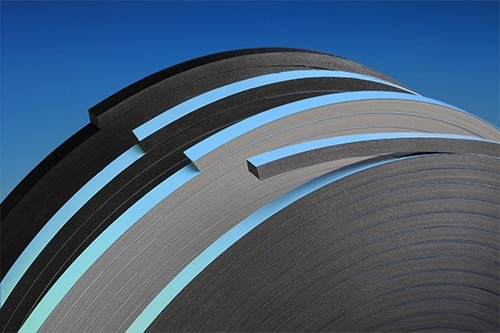

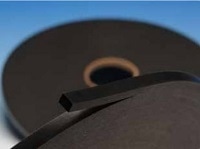

Thermalbond V2100 and V2200 Series is the original spacer tape that has been the industry standard for over 35 years. This open-cell foam tape is backed with double-sided adhesive to keep in the glass securely in place while the adhesive cures. Available in both black and grey, it has a low thermal conductivity to minimize heat transfer and is available in a range of thicknesses from 1/8” to 1/2” (3.2 mm to 12.7 mm). If you have a particular application in mind, custom widths are available. The high-strength polyurethane foam has low thermal conductivity that reduces heat transfer, inhibits condensation and provides superior resistance to weather, fungi, and oxidation.

Thermalbond V2100 is designed to be applied to glazing and may be used with for two-sided and four-sided systems. It excels through its load-bearing ability in both compression and shear. Thermalbond V2200 is designed for shop fabrication. The V2100 and V2200 series are compatible with all major brand structural silicone sealants.

Thermalbond® V2200 Series – Properties

| Property |

Test Method |

Value or Rating |

| Density: lbs/cu ft (kg/m3) |

ASTM D1667 |

31 (497) |

| Hardness: Shore A |

ASTM D2240 |

35 |

| Force to compress 10%: psi (kPa) |

ASTM D1667 |

31 (214) |

| Dynamic Tensile Adhesion: psi (kPa)* (15 min. dwell) |

NTP-11 |

55 (379) |

| Dynamic Shear Adhesion: psi (kPa)* (15 min. dwell) |

NTP-5 |

40 (276) |

| Static Shear Adhesion: Hours 1 psi load* |

NTP-57 |

2000+ |

| Tensile Strength: psi (kPa) |

ASTM D412 |

180 (1241) |

| Elongation of Foam: % |

ASTM D412 |

125% |

| Thermal Conductivity K factor: BTU•in/hr•ft2•ºF (w/m•ºC) |

ASTM C518 |

0.55 (0.08) |

| Migratory Staining of Acrylic Enamel: 200 hours of ultraviolet at 140 ºF |

ASTM D925 |

No Staining |

NTP-Norton Test Procedure

* Adhesive properties do not apply for Thermalbond® XPress™

Thermalbond® V2200 Series – Properties

| Property |

Test Method |

Value or Rating |

| Density: lbs/cu ft (kg/m3) |

ASTM D1667 |

22 (352) |

| Hardness: Shore A |

ASTM D2240 |

30 |

| Force to compress 10%: psi (kPa) |

ASTM D1667 |

16 (110) |

| Dynamic Tensile Adhesion: psi (kPa)* (15 min. dwell) |

NTP-11 |

45 (310) |

| Dynamic Shear Adhesion: psi (kPa)* (15 min. dwell) |

NTP-5 |

30 (206) |

| Static Shear Adhesion: Hours 1 psi load* |

NTP-57 |

2000+ |

| Tensile Strength: psi (kPa) |

ASTM D412 |

130 (896) |

| Elongation of Foam: % |

ASTM D412 |

105% |

| Thermal Conductivity K factor: BTU•in/hr•ft2•ºF (w/m•ºC) |

ASTM C518 |

0.55 (0.08) |

| Migratory Staining of Acrylic Enamel: 200 hours of ultraviolet at 140 ºF |

ASTM D925 |

No Staining |

NTP-Norton Test Procedure

* Adhesive properties do not apply for Thermalbond® XPress™

Thermalbond Grey has a light grey foam core with UV-stable grey-pigmented adhesive coatings. Designed to be used with grey and light-colored silicone adhesives, this tape is perfecting when working with lighter façades. Thermalbond Grey spacer tape can be purchased in either the V2100 or V2200 product series and features all of the same benefits of the standard Thermalbond product.

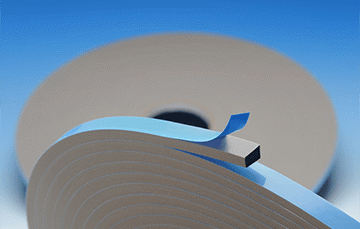

Thermalbond Xpress™ consists of the same foam core as the V2100 and V2200 product series and features the standard Thermalbond grade adhesive in a single-sided adhesive design. By removing the need for a liner, the one-sided adhesive simplifies and speeds up installation. With just a touch, the adhesive creates a strong, aggressive bond, eliminating the need for aluminum channel raceways. The low-friction coating prevents the formation of trapped air pockets, making Thermalbond Xpress a great product for glass floors.

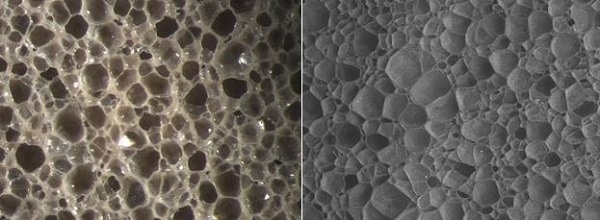

Thermalbond ―Open-Cell Foam Technology

During the development of Thermalbond, Saint-Gobain Performance Plastics worked closely alongside silicone adhesive manufacturers to guarantee chemical compatibility and optimize the spacer tape design. One-component silicones must be first exposed to atmospheric moisture to properly cure. Two-component silicones, however, have an internal catalyst and release methanol during the curing process. The polyurethane open-cell design of Thermalbond is composed of miniature holes or pores that are linked together and open to an external surface. These pores provide a channel for air and moisture to escape through to provide optimal curing of the silicone adhesive for one-component silicones and allow the exit of methanol from two-component silicones. If the silicone is not exposed to the proper amount of atmospheric moisture or methanol cannot leave the adhesive, curing will be slow or non-existent. Proper sealant adhesion is dependent on full curing of the silicone.

(Image: Open-cell foam at left and closed-cell foam at right).

Thermalbond is fabricated using open-cell polyurethane foam. Using open-cell foam technology is a key advantage and delivers superior performance compared to closed-cell foam alternatives. Closed-cell tapes do not allow the flow of air and moisture, which prevents them from reaching the silicone as well as blocking the volatile organic compounds (VOCs) that are a product of the silicone curing process from exiting the adhesive joint.

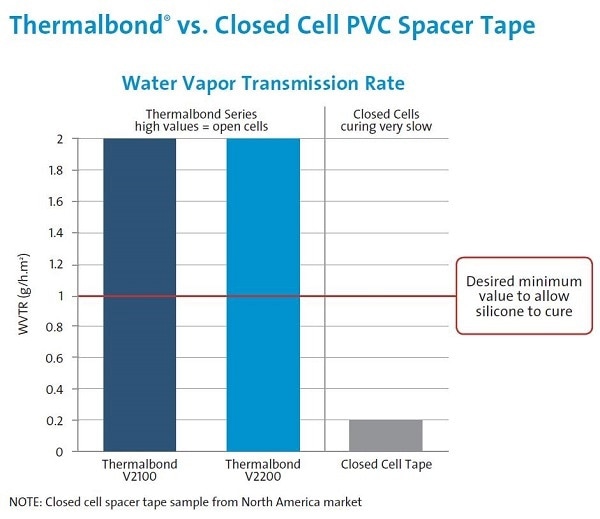

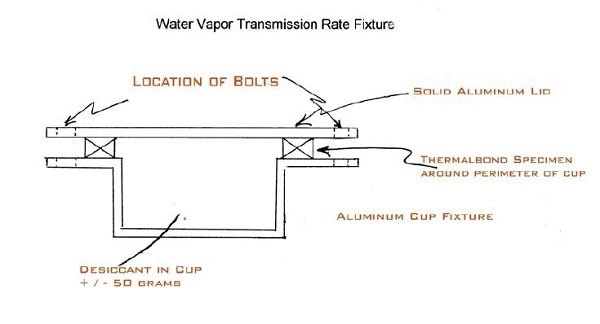

The permeability of moisture vapor through the foam material is measured using the moisture vapor transmission rate (MVTR), also referred to as the water vapor transmission rate (WVTR). For silicone to properly cure, the desired moisture vapor transmission rate should be at least 1 g/hr•m2.

To compare moisture vapor transmission rates, Thermalbond V2100 and V2200 were tested against a closed-cell PVC spacer tape sample from the North American market. The results prove that Thermalbond offers ten times the moisture vapor transmission rate and twice the minimum desired MVTR when compared to closed-cell spacer tape. Thermalbond provides the optimum MVTR, while the closed-cell PVC falls well below the minimum recommended value of 1 g/hr•m2

All tests performed were in accordance with ASTM E96 procedure A. Laboratory testing was under controlled conditions of 23±2 °C and 50±5 percent relative humidity with a sample testing compression of 10 percent. Siliporite NK10AP was the desiccant used for testing.

The outcome of the testing makes it plain that Thermalbond polyurethane open-cell technology is vastly superior to closed-cell PVC foam tapes. Any MVTR value lower than 1 g/hr•m2 is indicative of closed-cell foam, which would deny the silicone adequate moisture for rapid and proper curing. Being unable to fully cure could lead to movement of the glass prior to or after installation.

Load-Deformation Performance

Structural silicone glazed façades are only possible due to the silicone holding the glazed joint securely during its cure time, and then across the life of the building. The joint must be able to withstand a number of variables such as the weight of the components in shear mode, seismic activity, and effects of negative and positive wind loading.

Thermalbond spacer tape provides the exact space required for the silicone specified. Other tapes may seem to meet these requirements, but it is important to understand how the tape reacts under the load of the glass. As the silicone fully cures and develops full adhesion strength, the joint must remain completely static. Any variation in the spacer tape thickness during curing can invoke stress on the sealant, which is detrimental to silicone adhesion and strength. According to the Structural Glazing General Guidelines, by Sika Services AG, “Bonded units should not be exposed to stress until certain strength has developed.”

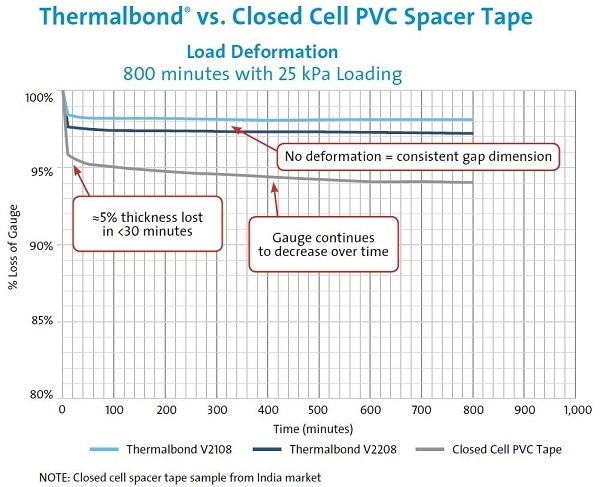

Thermalbond V2108 and V2208 underwent laboratory testing to compare their performance to that of non-open-cell PUR competition. The test placed the spacer tape under a compression equivalent to normal glass loading during fabrication. Any thickness deformation under load demonstrates that the structure is moving as the silicone cures, which compromises the joint.

Under a constant force of 25 kPa (the load of a standard window in structural silicone glazing applications), Thermalbond lost less than 3 percent of its thickness within the first 30 minutes and was then completely stable for the remainder of the 800-minute (13+ hour) test. By contrast, competition samples experienced approximately 5 percent loss in thickness and which continued to drop steadily over the next 10 hours of the test.

Variation in tape gap is expressed as a percent of original thickness. All measurements are performed using an Anton Paar MCR301 plate/plate rheometer.

Calculations assumed:

- 2.5 LM x 1.5 LM x 10 mm IG = 50 kg/m2 glass weight

- 8 LM x 8 mm tape width = .064 m2 tape = 2,922 kg/m2/28 kPa loading

These tests reveal serious concerns in how closed-cell PVC spacer tape is able to hold the glass during loading while the silicone cures. Both Thermalbond products demonstrated superior deformation characteristics while under load during the vital silicone curing time period.

Using closed-cell PVC spacer tape, the glazed joint was able to move during the critical cure cycle when due to the combination of low moisture vapor transmission rate, which causes longer curing times, and poor load-deformation. Thermalbond’s ideal moisture vapor transmission rate and low load-deformation characteristics provide the perfect conditions to hold the structural joint stable.

The Saint-Gobain Difference

Saint-Gobain’s can trace their history dates 1665, the year the Royal Glass Works was established in France. Today, Saint-Gobain is one of the top 100 industrial companies in the world and a market leader in the manufacture and distribution of building materials and innovative solutions for energy efficiency and environmental protection. Saint-Gobain is proud of their constant innovation, with a fifth of their current products being developed in the past five years.

Thermalbond tapes have been successfully used in hundreds of silicone structural glazing applications throughout the world for over than 35 years without failure. The unparalleled performance of the open-cell polyurethane foam technology is the reason architects and façade specifiers request Thermalbond by name and trust it to bring their dreams and designs to life.

Delivering the highest quality and longest lasting structural glazing spacer tape is just a call or click away. Please contact Saint-Gobain now for details.

This information has been sourced, reviewed and adapted from materials provided by Saint-Gobain Tape Solutions.

For more information on this source, please visit Saint-Gobain Tape Solutions.