The weldability of steel is primarily influenced by its carbon content. Additionally, the influence of different elements, such as, silicon (Si), nickel (Ni), copper (Cu), vanadium (V), molybdenum (Mo), chromium (Cr), and manganese (Mg) may impact its carbon equivalence (CE).

Carbon equivalence was originally developed to assign a numerical value for a given steel composition indicating the carbon content which would contribute to an equivalent level of hardenability for that steel.

Carbon equivalence also shows how the composition of materials contributes to the cold-cracking (hydrogen cracking) vulnerability of the steel. Carbon equivalent calculations are utilized to estimate heat-affected zone (HAZ) hardenability in welding.

Understanding variations in chemistry through the carbon equivalence calculation helps to establish the compatibility of the properties of two materials being joined together via filler metal component.

Figure 1. Carbon equivalence (CE) is an essential calculation prior to performing welding.

If the components are too disimilar, or if the carbon equivalent reaches a higher, unacceptable value (Table 1), then special precautions may be required both before and during the welding process.

The welding precautions that may be taken are the use of low hydrogen electrodes, prescriptive heat treatment, and controlling the heat input. These guidelines are outlined in the NACE (National Association of Corrosion Engineers) standards (NACE MR0175/ISO 15156 and NACE MR0103/ISO17945).

These standards were designed for natural gas, offshore, and petrochemical applications where carbon steels in the company of hydrogen sulfide (H2S, sour service) are prone to hydrogen stress cracking (HSC) or sulfide stress cracking (SSC).

| Common CE Value Classifications |

| Carbon Equivalent (CE) |

Weldability |

| Up to 0.35 |

Excellent |

| 0.36-0.40 |

Very Good |

| 0.41-0.45 |

Good |

| 0.46-0.50 |

Fair |

| Over 0.50 |

Poor |

Table 1. Common Carbon Equivalence Classifications

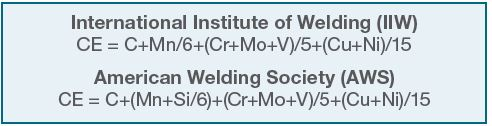

There are two frequently utilized equations for expressing carbon equivalence produced by the International Institute of Welding (IIW), and the American Welding Society (AWS) (shown in Figure 2).

Figure 2. Carbon equivalence (CE) calculations as defined by the International Institue of Welding (IIW), and American Welding Society (AWS).

Niton Apollo Handheld LIBS Analyzer

There is a new tool avaliable to professionals performing material analysis. The Thermo Scientific™ Niton™ Apollo™ handheld LIBS analyzer uses Laser Induced Breakdown Spectroscopy (LIBS) to perform inspection of critical assets and carbon equivalent calculations.

Weighing only 6.4 lbs. (2.9 kg.), the Niton Apollo specializes in the analysis of carbon content in a portable, easy-to-use form factor. The requirement for large Optical Emission Spectroscopy (OES) carts is removed in a number of situations.

Supplied with a high purity argon purge and an effective laser, the Niton Apollo provides laboratory-quality results in about 10 seconds.

Along with the calculation of carbon equivalents, users can determine alloy grades, program pseudo elements, and execute advanced averaging. The data is presented in real time to allow for efficient and fast decision making.

Test Method and Results

Similar to alternative elemental technologies, sample preparation is needed when utilizing the Niton Apollo to uphold the most dependable results and performance.

Many samples of carbon steels employed in a range of applications were selected for investigation utilizing the Niton Apollo.

Chemistry and ensuing carbon equivalent calculations are displayed using both AWS and IIW formulae as an evaluation of repeatability testing (shown in Table 2).

| Sample |

CE-IIW |

CE-AWS |

C |

Mn |

Cu |

Si |

Ni |

Cr |

Mo |

V |

Ti |

Al |

| X65 |

0.287 |

0.335 |

0.049 |

1.061 |

0.118 |

0.286 |

0.117 |

0.090 |

0.056 |

0.081 |

0.005 |

0.038 |

| X65 |

0.306 |

0.352 |

0.042 |

1.209 |

0.118 |

0.279 |

0.095 |

0.087 |

0.064 |

0.087 |

0.005 |

0.024 |

| X65 |

0.291 |

0.338 |

0.040 |

1.134 |

0.125 |

0.277 |

0.105 |

0.091 |

0.061 |

0.085 |

0.005 |

0.030 |

| X65 |

0.290 |

0.338 |

0.042 |

1.116 |

0.118 |

0.284 |

0.112 |

0.096 |

0.065 |

0.077 |

0.005 |

0.031 |

| X65 |

0.300 |

0.346 |

0.039 |

1.196 |

0.116 |

0.276 |

0.094 |

0.080 |

0.068 |

0.088 |

0.005 |

0.028 |

| X65 |

0.294 |

0.341 |

0.034 |

1.171 |

0.113 |

0.280 |

0.102 |

0.092 |

0.078 |

0.083 |

0.005 |

0.030 |

| X65 |

0.278 |

0.326 |

0.039 |

1.091 |

0.124 |

0.289 |

0.106 |

0.090 |

0.049 |

0.069 |

0.006 |

0.032 |

| X65 |

0.295 |

0.340 |

0.046 |

1.127 |

0.116 |

0.273 |

0.109 |

0.087 |

0.063 |

0.081 |

0.005 |

0.034 |

| X65 |

0.282 |

0.333 |

0.041 |

1.078 |

0.117 |

0.310 |

0.107 |

0.095 |

0.059 |

0.075 |

0.004 |

0.038 |

| X6 |

0.280 |

0.325 |

0.036 |

1.115 |

0.110 |

0.275 |

0.098 |

0.089 |

0.053 |

0.079 |

0.005 |

0.034 |

| AVG |

0.290 |

0.337 |

0.041 |

1.130 |

0.118 |

0.283 |

0.105 |

0.090 |

0.062 |

0.080 |

0.005 |

0.032 |

| STDEV |

0.009 |

0.008 |

0.004 |

0.049 |

0.004 |

0.011 |

0.007 |

0.005 |

0.008 |

0.006 |

0.000 |

0.004 |

| RSD |

3.1% |

2.4% |

10.7% |

4.3% |

3.8% |

3.8% |

7.1% |

5.1% |

13.3% |

7.2% |

9.1% |

13.7% |

Table 2.

Conclusion

The performance of the Niton Apollo handheld LIBS analyzer features the ability to precisely and repeatedly record carbon content, along with instantly calculating the carbon equivalence utilizing a prescribed formula through the pseudo element feature.

Whether working at heights in a refinery, in a pipeline trench, or off-shore on an oil platform, the Niton Apollo is the perfect tool for investigation in a host of different industries providing the greatest productivity and safety.

Acknowledgments

Produced from materials originally authored by Brian Wilson from Thermo Fisher Scientific.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Handheld Elemental & Radiation Detection.

For more information on this source, please visit Thermo Fisher Scientific – Handheld Elemental & Radiation Detection.