The components of high-quality lasers can be made of many different materials. Many high-power and solid-state lasers use ceramic materials to generate a laser beam and are seen as an alternative material to glass and single crystals, which are two other materials that are commonly used to generate a laser beam. Here, different ceramic laser materials will be discussed, as well as how they have advanced over the years as lasers have become more powerful.

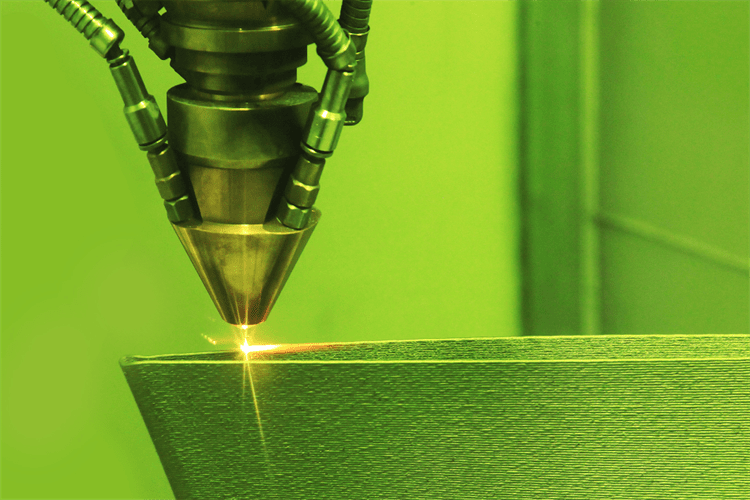

Image Credit: sspopov/Shutterstock.com

The ceramic raw materials used in lasers have come a long way since their first inception in 1964. The development has stemmed from the creation of new ceramic materials, as well as advances in powder synthesis and ceramic sintering methods, which have introduced more high-quality ceramics to be used in advanced optical applications such as lasers.

The continued use of ceramics as laser materials has grown over the last few decades because solid-state lasers (in which ceramics are used) have many advantages over gas lasers and free-electron lasers, including smaller footprints, enhanced mobilities, and better overall performance.

Why Ceramics are Used as Laser Materials

Ceramic materials are used in high-powered lasers because the high power induces thermal gradients which, in turn, can cause either beam distortions or thermal birefringence that can affect the quality of the laser beam.

This means materials that have low thermal expansion coefficients, low dependence of the index of refraction on temperature, and low dependence on the optical path length of temperature are highly desirable. The properties of ceramics used within lasers are typically desirable in one or more of these areas, hence their use.

The use of some of the more complex ceramics with higher-end properties was not possible for laser applications in the past, and many applications were hindered due to issues of varying compositions, crucible interactions, phase transitions, and poor solubility of the rare earth metals used in the ceramic (especially in doped ceramics).

However, ceramics have since become viable materials due to advances in ceramization processes that have provided low-temperature synthesis routes for various transparent polycrystalline ceramics.

These processing advances have meant that polycrystalline ceramic materials can be used as laser materials. Ceramic materials produced by this method have the appearance of a single crystal but are polycrystalline at the atomic level and still possess grain boundaries.

However, the grain boundaries are often clean, free from pores, and lack impurities, making the ceramics highly transparent and suitable for generating laser beams. These method advances have also enabled transparent polycrystalline ceramics to be doped with rare earth elements and made into complex shapes (all at scale), allowing a wide variety of strong, tough, and effective laser materials to be produced. This has helped to expand their use over the years.

Some of the key properties that make the different ceramic materials superior to their single crystal and glass counterparts include a lower optical scattering (due to uniform and ordered earth metals in the ceramics), a much higher strength and toughness (due to a high fracture toughness), and a comparable or better laser damage threshold (which varies depending on the ceramic class).

Types of Ceramic Laser Materials

Many different materials can be used to create lasers, and the number of materials available is growing. The first ceramic to be used in a laser was Dy2+:CaF2 in 1964, and, since then, both doped and undoped ceramic materials have been tested.

The materials trialed over the years include metal oxide ceramics, yttrium aluminum garnet (YAG), non-oxide ceramics, composite ceramics, sesquioxide ceramics, and non-cubic doped fluorapatite ceramics. All of these materials have doped and undoped versions (with various dopants being used), which show different properties from each other, with noticeable differences also being present between doped and undoped versions of the same material.

Sesquioxide materials are known to have the best thermal conductivities out of all the different laser materials, but as it is one of the newer ceramic laser materials, its use has not been widely utilized yet. As it stands, YAG laser materials (which have been around since 1995) have experienced the most widespread research and use. They have been used in both microchip lasers and ultrashort pulse lasers, as well as in some of the highest lasers developed (in terms of KW output power).

YAG laser materials were also used in the lasers that broke both the 1 KW and 100 KW output power records, and their use is still growing to this day. Ceramic laser systems are always advancing, and their use will likely continue to grow in the future, much like it has over the last 60 years.

More from AZoM: Advanced Ceramics – The Evolution, Classification, Properties, Production, Firing, Finishing and Design of Advanced Ceramics

References and Further Reading

“Ceramic laser materials”- Ikesue A. and Aung Y. L, Nature Photonics, 2008, DOI: 10.1038/nphoton.2008.243

“Ceramic laser materials: Past and present”- Sanghera J. et al, Optical Materials, 2013, DOI: 10.1016/j.optmat.2012.04.021

“Ceramic Laser Materials”- Sanghera J. et al, Materials (Basel), 2012, DOI: 10.3390/ma5020258

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.