Interview conducted by Courtney Garner, MAMar 30 2020

Interview conducted by Courtney Garner, MAMar 30 2020

AZoMaterials spoke to Scott Mittl, Vice President of Sales at Insaco®, about how composite materials are defined, how composites are machined by Insaco, and the expected direction of CMC materials in the future.

Could you give our readers an overview of what a composite material is?

A common definition of a composite is a material made from two or more constituent materials with significantly different physical or chemical properties that, when combined, produce a material with characteristics different from the individual components. It is usually desired that the composite materials have improved strengths from both materials, usually compensating for the original materials’ weaknesses. Composites are usually classified by the type of reinforcements they use. These reinforcements are embedded into a matrix which could be thought of as the base material, with the reinforcements used for strengthening.

Why are the names of composites are so descriptive?

The name of the composite material will usually include the type of reinforcement. The reinforcements could include fiber reinforcement, particulate reinforcement, and structural reinforcement.

An example of a composite based upon reinforcement would be reinforced concrete. Concrete is generally strong in compression but poor in tension. Adding rebar or a metal mesh to the concrete improves the tensile properties of the material.

A way to further describe the composite material is to identify the matrix. There are common classes of composites based upon matrix. Some of the more common types of matrix composite materials include carbon matrix composites, polymer-matrix composites, metal-matrix composites, and ceramic-matrix composites. Many of these are widely used in numerous engineering applications.

How does Insaco work with composite materials?

We actually do not make materials, our business is to provide the service of converting challenging and difficult to machine materials to a final configuration that makes them useful for end-use applications.

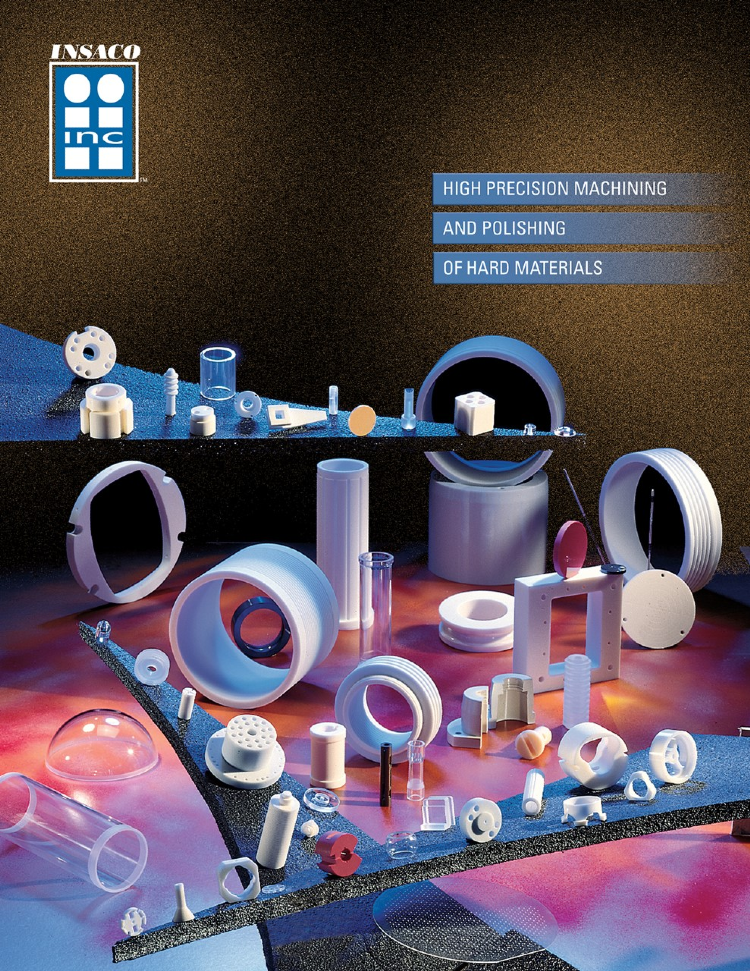

Image Credit: Insaco

Can Insaco machine any material or are there limitations?

No, Insaco can not machine any material, we will only be effective with our equipment when machining materials where a diamond grinding wheel is appropriate. This includes sapphire plus most ceramic oxides, ceramic nitrides, and ceramic carbides. Additionally, composites where there is a ceramic matrix and/or a ceramic reinforcement such that it can be classified as a ceramic matrix composite material would also be able to be machined in our facility.

Which composite materials does Insaco commonly machine in their facility?

We focus most of our efforts on the ceramic matrix composite materials otherwise known as CMC. Our facility is full of all kinds of grinding and polishing equipment. However, because all of our machines have diamond grinding wheels we want to only work on ceramic based materials. The diamond wheels work wonderfully on ceramic materials but do not work well on metals or plastics. Usually a composite which is mostly a metal or plastic will smear and the material will not be effectively machined.

What are the current challenges of machining composite materials?

Composites are only one of many different types of materials we machine at Insaco on a daily basis. Since we do not make materials, we are often asked to machine customer supplied materials, whether they are composites or otherwise. Occasionally they are so hard we call this material “kryptonite” because they are incredibly difficult if not impossible to machine. Therefore, quoting the machining of these materials can take some time, and usually requires an approved SDS and some preliminary test grinding prior to offering a quote for a finished part.

What is the expected direction of CMC materials in the future?

Ceramic matrix composite materials and the development of composite materials overall is still in its infancy. These materials are an important part of our business and we expect this to grow given our capability to machine grind and polish them. Our experience has been that advanced and engineered materials are usually wanted, but can only be justified when needed. As the material science continues to develop it is likely these materials will become increasingly needed as they become more customizable, allowing for further improvements in certain material properties based upon the composite combination.

Do you have anything more you want to convey about CMC’s?

At Insaco we sometimes say that we have a tendency to work on the bleeding edge of technology, as opposed to the cutting edge of technology (the pun is intended). I use this play on a colloquialism in order to identify that our effort is always trying to advance material science by providing capabilities and creating features in various traditional and newly developed materials to be used in unique end-use applications.

Putting forth this effort can sometimes cost more than expected (hence the “bleeding”), but the end results can usually justify the expense. We have found this model to be the most efficient way to advance various ceramic materials into an end-use application in aerospace, scientific analysis, medical, semiconductor, and compound semiconductor industries.

Could you tell our readers more about Insaco?

Since 1947 Insaco has been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartz. We machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricity. Our customers typically have a critical application that requires extremely tight tolerances in ultra-hard materials. We also have the capability to grind and polish spherical radius parts in a variety of hard materials, both inside and outside diameters, to optical requirements.

Image Credit: Insaco

About Scott D. Mittl

Scott D. Mittl, Vice President of Sales, has been an employee of Insaco since 1990 and is resp onsible for sales engineering activity including quotations and account management.

onsible for sales engineering activity including quotations and account management.

He takes an aggressive proactive approach to developing new customers and new product applications. This approach includes developing subcontractors to further enhance Insaco's machining capability in any non-metallic material.

He has the technical expertise and experience in materials to aid customers in successfully designing products out of materials commonly machined by Insaco. He has a B.A. in Applied Sciences and a B.S. in Metallurgy and Materials Engineering from Lehigh University and is a member of the American Ceramic Society.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.