There is a growing rate in the utilization of automation in materials testing, particularly since even the smallest disruptions can change measured values. Monotonous and time-consuming tasks are also often performed by robots.

ZwickRoell provides a large range of possibilities for automation in materials testing. Testing systems range from fully-automated testing laboratories that work around the clock to efficient automation of small series tests by utilizing collaborating robots in the lab.

For example, classic robotic testing systems based on industry robots have been employed successfully for years. They can move even heavy specimens because of their high load capacity.

The large scope of specimen magazines makes them perfect for long test series – hundreds, and even thousands of specimens are processed autonomously, magazine by magazine. In this case, through the utilization of different roboTest testing systems from ZwickRoell.

Together with the corresponding testing machine, they are not only the ideal solution for standard tensile tests on plastics or metals under normal conditions, but flexure tests, notch impact and puncture, and temperature-controlled tensile tests, in addition to measurements of ball indentation hardness can also be automated.

Image Credit: ZwickRoell GmbH Co. KG

Complete Systems

Not only can the actual test be carried out without employee intervention, but by utilizing AGVs (automated guided vehicles) and additional handling robots that are coordinated with ZwickRoell’s autoEdition 3. Just like the robots utilized for the testing process, ZwickRoell also builds fully autonomous testing laboratories.

They run 24 hours a day when necessary, and assume materials testing autonomously, from the placement of the specimens onto a transport belt to the disposal of the destroyed specimen. All that remains for workers to do are specimen production and preparation.

A fully automated testing lab is particularly worthwhile for quality assurance in ongoing production with high material throughput. After removing the materials or specimens from the manufacturing process, they are formed into the size and shape needed. Each specimen is given a 2D code or barcode and can be clearly and automatically identified in the system.

The only thing which remains is the transfer of the specimens to the robot testing lab: the specimens are put onto a belt conveyor and sent risk-free within reach of the robot, they are recognized by their code then assigned to the correct test and testing machine, and sorted onto the proper tray.

Driverless Transport

AGVs perform further transport, which takes the trays to the corresponding testing machine. They create a map of their surroundings and independently determine the ideal route to their destination via an integrated laser navigation system.

They are superior to the classic solutions that, for example, have to follow a wire embedded in their path or an adhered contrast line as they have autonomous navigation.

Their only choice to react to obstacles is by communicating with an operator or to stop and wait until their path is clear. The delivery is stopped if the path is not cleared, and in the worst case, until there is no material left at the target destination, and an employee must go and look for it.

The solution from ZwickRoell has the ability to drive around obstacles, ensuring an uninterrupted chain of transport. Once the AGV has arrived at the intended testing machine, it loads the tray with the new specimens into the testing system’s magazine.

One of the recognized robotic testing systems from ZwickRoell, for instance the roboTest L, assumes processing of the delivered specimens: equipping the testing machine, the testing process and the transfer of data to the customer’s software systems and, of course, the removal of the destroyed specimen is completely automated.

So that the test data can be linked with the corresponding specimen correctly, the identification numbers of the specimens are read by the cameras. An AGV carries the empty trays and transports them back to specimen preparation. There they are refilled and the cycle restarts.

Automating Small Series

Up until now, the work which is performed successfully at a large scale saving a lot of time, has not been economical at a small scale. The installation of stationary robotic testing systems takes time and is costly, in addition to the costs of specialists who are familiar with their programming.

Furthermore, depending on the system, a large range of safety measures are needed to avoid accidents and injuries: the powerful industry robots are not intended for utilization in direct collaboration with humans.

If a person is within their working range, they do not have the option to react to their environment such as through an emergency shut-off. A safety barrier is required in most instances, which eliminates the direct interaction of robot and man. So, up until now small series tests have been performed by humans.

It was much faster to entrust an employee with 50 Charpy impact tests or 20 tensile tests, than to install a large robotic testing system, even if a task is extremely monotonous.

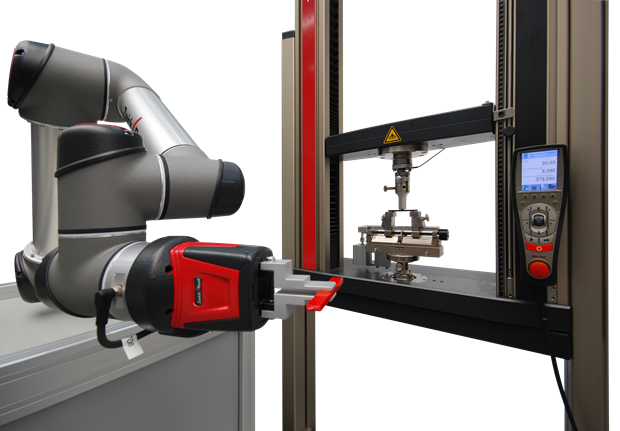

With roboTest N, for the first time ZwickRoell can provide the possibility to automate series testing with a small number of specimens with a lower specimen weight. The system is fully integrated in ZwickRoell’s autoEdition 3 and testXpert III, based on a smart robot.

So, special robot programming and operating knowledge or a robot operator terminal are not needed. Instead the roboTest N, in the truest sense of the word, is taken “by the hand” and taught the necessary point of reference.

Parameters are set in a familiar software environment in regards to software. Not only is the setup of the smart robot uncomplicated and easy, its force and work speed are similar to human proportions. Sensors detect external influences and stop the system if something gets in its way.

So, the roboTest N can work alongside persons without the requirement for additional safety measures once cleared with laboratory safety personnel, locked off work areas are not needed.

Diverse Application Options

The light weight robot is fastened to a movable table which is intended specifically for the robot. Application options are widely expanded via this mobile base. The smart robot may be moved to the appropriate testing machine and connected to the system.

This not only enables the uncomplicated processing of alternating small series, but also the automated performance of a number of tests. Compression and tensile tests can be as autonomously processed as Charpy impact tests, three-point-flexure tests, or hardness tests.

The movable base also supplies space for custom manufactured magazines – for instance in a 3D printer – from which the roboTest N can take additional specimens automatically.

The robot extends the workday by the contents in a magazine if it is started just prior to the end of a shift, and the results are available at the beginning of the following day. Automation of monotonous standard tests enable qualified employees to focus on more complex test applications which need more attention.

The independence from the operator which is attained via the utilization of a robot is also an advantage. The uniform movement sequences in feeding the testing machine and with that, consistent positioning of the specimens, stop user errors or inaccuracies and heighten the reliability of test results.

Conclusion

Robotic testing systems supply the user with multiple advantages for series testing, from time savings through to the improvement of the informative value of the test results. ZwickRoell covers the complete range of testing automation with various roboTest testing systems – from short-term support for continually changing small series in the lab, through to fully automated testing laboratories, without human intervention.

Image Credit: ZwickRoell GmbH Co. KG

This information has been sourced, reviewed and adapted from materials provided by ZwickRoell.

For more information on this source, please visit ZwickRoell GmbH Co. KG