Materials testing tests the accuracy and load capacity of materials in different environmental conditions. Materials testing is not only performed at research institutes, it also helps companies to gather valuable knowledge for the improvement of existing products and the development of new ones.

The key principle of materials testing is mechanical loading of a specimen or material up to a certain deformation or to break. The material properties which come as a result of this are shown through material characteristics.

Image Credit: ZwickRoell GmbH Co. KG

Test Methods

There are a number of test methods which can be applied in materials testing:

Dynamic Testing

For dynamic testing the load periodically influences the specimen over a longer period of time or the specimen is subjected to an impact load. Dynamic materials testing refers to the (destructive) test on components or materials, which is carried out with quick movement (dynamic). Examples include drop weight testers, pendulum impact testers, and high-speed tests (puncture or high-speed tensile tests).

(Quasi-) Static Testing

Loading on the specimen is slow and constant in (quasi-) static testing or static materials testing. In static materials testing the deformation behavior and strength of components and specimens, mainly subjected to compression, tension, shearing, torsion and flexure is established. Static materials testing, relative to dynamic materials testing is performed with lower test speeds.

Cyclic Materials Testing

In cyclic materials testing, loading on the specimen is performed in continuously recurring load cycles. These load cycles can be in the form of tensile/compression, pulsating, triangle shape,or alternating load in sinusoidal shape, etc., depending on the machine.

Destructive Materials Testing

In destructive materials testing, the specimens are taken from a material and tested for chemical or mechanical loads. The specimen is altered (on the surface) or destroyed. The tested component, or material specimen, can no longer be used after the test.

Destructive materials testing plays a particularly important part in aerospace engineering and the automotive industry, since in these cases material fatigue presents an extremely high risk factor. Yet, materials and components testing has also become crucial in medical engineering.

In most test techniques the specimen is destroyed:

- Impact test

- Sheet metal forming

- Drop weight test

- High-speed tensile test

- Tensile test

- Biaxial test

- Compression test/crush test

- Creep test

- Flexure test

- Fatigue test

- Puncture test

- Torsion test

- Shear test

Non-Destructive Materials Testing

The quality of a workpiece is tested without damaging it when using non-destructive materials testing. Using this approach, it can be ensured that the material quality is high enough for further processing and that it can stand up to loads reliably, for the long-term.

Non-destructive test techniques include:

- Static and dynamic friction test

- Component testing

- Hardness test

- Function test

- Rebound test

Application Examples for Non-Destructive Materials Testing

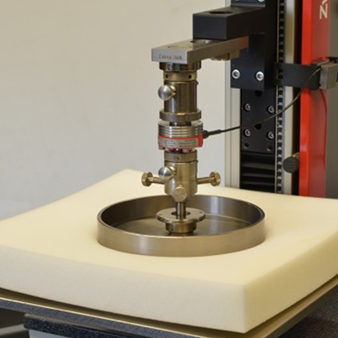

Film - The static and dynamic friction test is part of non-destructive materials testing. Image Credit: ZwickRoell GmbH Co. KG

Foam material - Indentation hardness is measured on a foam specimen. Image Credit: ZwickRoell GmbH Co. KG

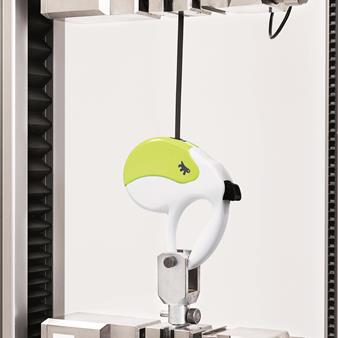

Spray bottle - Non-destructive function test on a spray bottle. Image Credit: ZwickRoell GmbH Co. KG

Dog leash - Non-destructive materials testing on a dog leash. Image Credit: ZwickRoell GmbH Co. KG

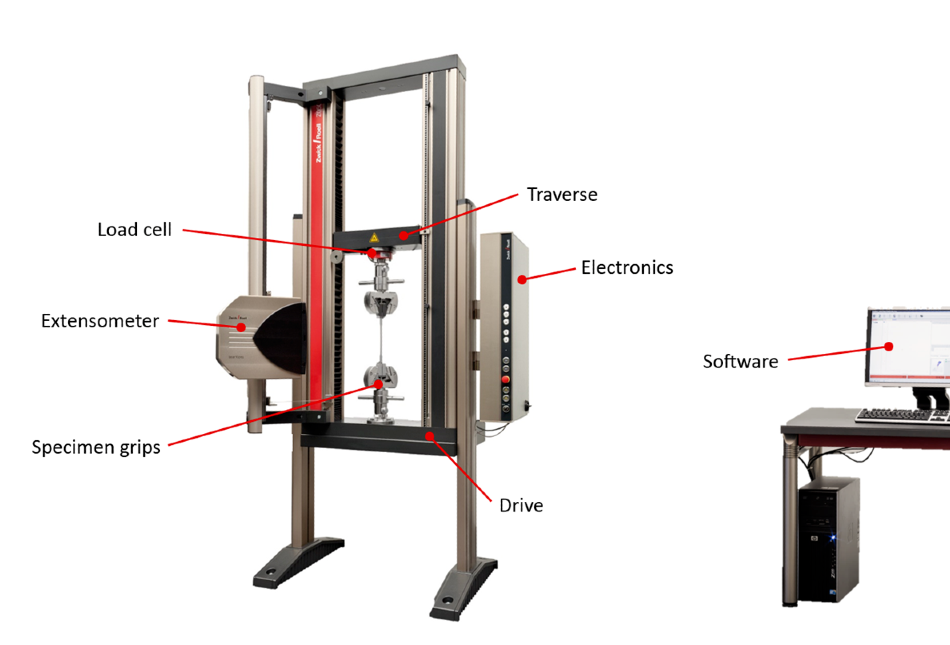

Materials Testing Machine Parts and Components

Fundamentally, all materials testing machines have comparable parts. Many types of components are adapted to the load frame:

- Software

- Specimen grips

- Electronics

- Load cells

- Extensometers

- Crosshead

- Drive

Image Credit: ZwickRoell GmbH Co. KG

ZwickRoell – Industry Materials Testing Expert

Materials testing includes a wide range of test techniques with which the material characteristics and behavior of finished parts and components (components testing) or standard specimen materials under mechanical, chemical, and thermal loads are established. The test technique requirements vary among different industries.

ZwickRoell machines are utilized in research and development and quality assurance in over 20 industries. Their experts possess a detailed understanding of the individual requirements of the different industries and can meet specific testing needs with state-of-the-art solutions.

This information has been sourced, reviewed and adapted from materials provided by ZwickRoell.

For more information on this source, please visit ZwickRoell GmbH Co. KG