Particle size analysis has a wide variety of applications which encompass virtually all industries. There are multiple automated techniques that exist for measuring particle size distribution. Nearly all of these report particle size in units of equivalent spherical diameter. This is required because there is ambiguity when describing the diameter of an irregularly shaped particle, and also because of inherent constraints in the instrument detection system.

Of the sizing instruments available, Laser diffraction particle size analyzers are extensively used in many industries and have various applications. Although the LD method is a very efficient, reproducible and robust method, it does have significant shortcomings when particles deviate from spherical to more irregularly shaped morphology. For example, a needle shaped 90 m particle may represent itself as having an equivalent sphere diameter of only a few microns in laser diffractions, based on its angular presentation to the LD detectors.

As a result of this phenomenon, as the particle deviates from spherical, the irregularity in circularity presented by that particle can acutely influence the PSD of the population that is obtained. This can mean that the distribution widens, whilst the actual size of the particles remain consistent and uniform. For example, as a result of random orientation, a rod-like particle can present itself as a rectangle in laser diffraction, or as a circle which represents the diameter of the rod. It can also present to the laser detection system in any possible combination of those orientations.

Consideration of the Effect of Particle Shape to Powder Flow

Particle size distribution is one of the most significant influences on the flow behavior of powders. In order to ensure uninhibited flow character, most operators have included robust particle-sizing analytical tools to control particle size distribution (PSD) to the levels desired. Particle shape is also an important factor in determining and controlling the powder flow and performance character. Particles segregate by their difference in mobility based on size, but shape also has a significant influence on that mobility.

Shape controls the magnitude and orientation of the interparticle forces. Particles that are similar in size but that have different shapes can behave very differently. Substantial mechanical interlocking and resistance to flow can be caused by particles with irregularly shaped surfaces. Flow behaviour can also be influenced by surface irregularities or roughness.

In fluidized bed reactors, used for catalytic chemical reactions, the reaction shape deviates from spherical to a flattened form which compromises the reaction kinetics 1. Interparticle mass transfer rates can be minimized by irregularly shaped particles. Catalyst deactivation rates increase with complex or irregularly shaped particles showing an increase in carbon formation rates 2.

Careful consideration of shape is recommended to complement particle size data in inhalation drug therapies. Shape directly impacts flowability, aerosolization and deposition. When compared to other shapes of the same or similar PSD, pollen shaped particles have been shown to exhibit improved higher fine particle fractions, more significant emitted dose, and improved flowability 3.

Shape has a definitive influence on powder spreadability in metal powder characterization for additive manufacturing. The more spherical the particle, the more positive the contribution towards higher particle packing densities and powder flowability within the powder bed. Shape has also been observed to influence the apparent density of the powder feedstock, and this can have a direct effect on the final density of the manufactured part 4.

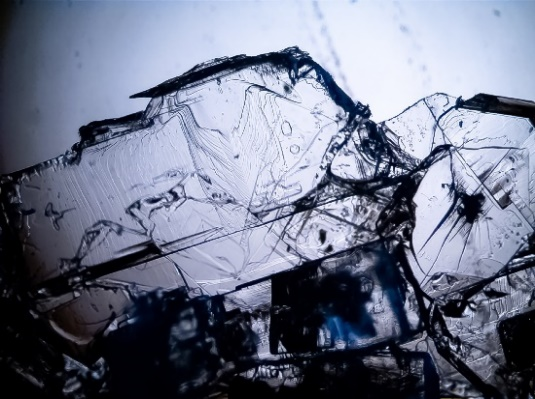

In pharmaceuticals, it is vital to control the crystal form and shape as they effect downstream processing operations, for example drying, milling and filtration. Shape also determines the chemical and physical properties of the API, for example solubility and dissolution rate 5.

Due to its central importance for specific therapeutic actions, there is increasing interest in shape control of the crystalline form. Shape influences stability, as well as other complexities associated with solid-liquid separations when irregular shapes like platelets, dendrite formations, and needles are present.

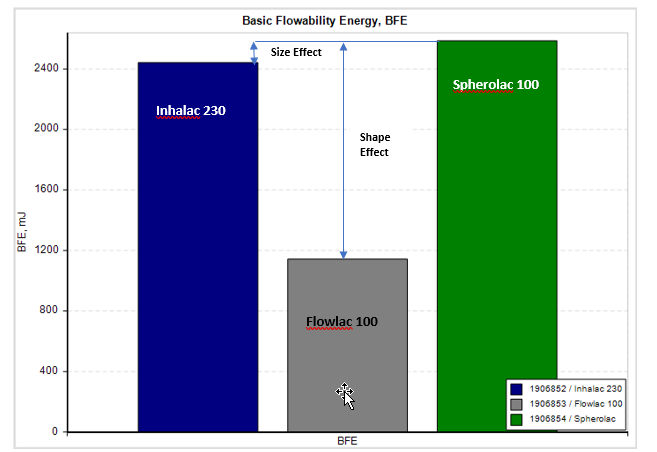

Data generated from the Freeman FT4 Powder Rheometer.

Three commercial samples of lactose (FlowLac 100, SpheroLac 100, and Inhalac 230) were analyzed in order to illustrate the influence of shape in pharmaceutical excipients. The SpheroLac 100 and FlowLac 100 have very similar PSDs, but show a difference in actual shape. Conversely, the SpheroLac 100 and the Inhalac 230 differ with regards to PSD but have similar shapes.

In this example, it can be observed that the Basic Flowability Energy difference is influenced most by the difference in shape morphology of the samples tested compared to the influence of particle size distribution.

Integrating Dynamic Image Analysis into a Laser Diffraction Particle-Sizing Workflow

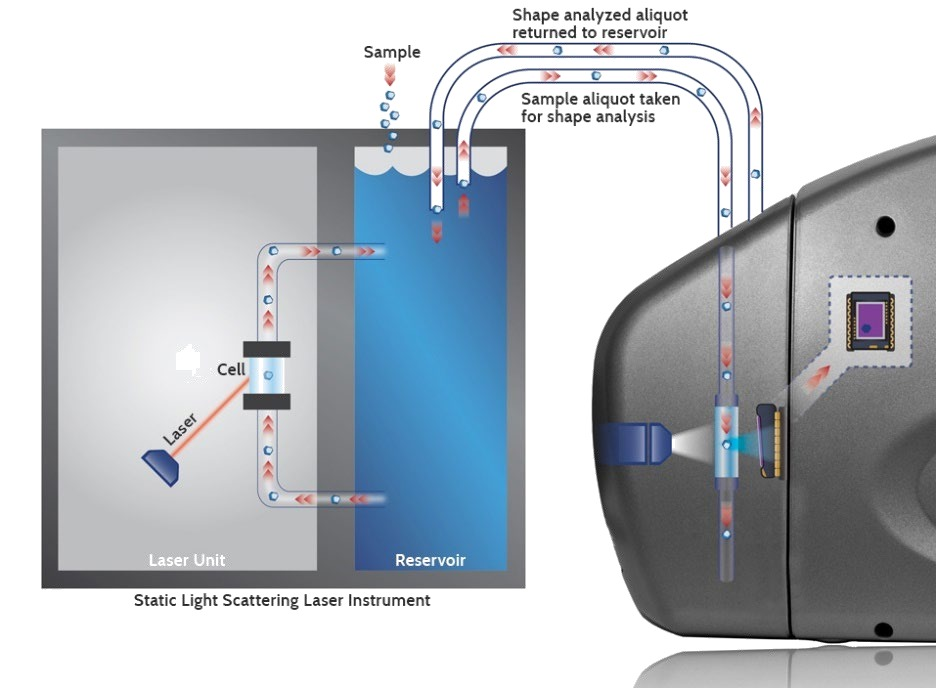

A dynamic imaging shape analyzer can now be integrated directly in the workflow, fluid path of a particle sizing laser diffraction instrument. The newly introduced Particle Insight SentinelPro Dynamic Image Analyzer from Vision Analytical is an example of such a device.

The SentinelProTM Shape Module takes an aliquot of sample from the reservoir of the user’s laser light scattering instrument automatically. It does not require any changes or re-validation of the current process or method, but can be easily integrated within the fluid path of the existing size-only instrument.

The SentinelPro taps into the sample reservoir of the sizing instrument as the sample is being analyzed and removes an aliquot of no more than 30 ml of the sample. It then performs a shape analysis in real time and returns the sample to the existing instrument. This is all done without jeopardizing the sample or the integrity of the results for the size obtained by the particle sizing instrument.

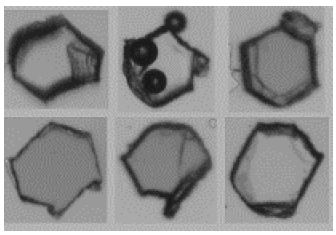

Dynamic Imaging uses high-resolution, high speed optics to capture each individual particle as it is streamed continuously past the detection zone of a known and controlled volume. This type of system permits random orientation so that every single particle’s physical size and shape can be measured and then represented as a grayscale image and as a binary fingerprint. These can be used for data deconvolution. Having a continuous flow, which results in random orientation, means that Dynamic Imaging is not compromised by spatial orientation limitations, as has been observed with laser diffraction. Furthermore, it is possible to determine particle concentration because of the high-speed particle capture rate and the known volume in the detection area.

This technique can also be used to report number-based valuation for the population, as well as the volume-based results that are usually associated with LD. The numbers-based evaluation is advantageous because it allows the user to look at the entire population, so as to uncover information about fines, fractures particles from milling, etc. These may not be detected or represented in the LD provided volume-based data because of their lower volume-weighted number. The additional information provided by dynamic imaging can supply more information about morphology in particle sizing workflow.

Laser diffraction (LD) is a powerful technique, however, it must be noted that several areas may limit the reported PSD accuracy because of the LD architecture and its following limitations:

- Small surface irregularities can produce ghost peaks

- The limited angular resolution of the detectors employed

- The assumptions utilized by proprietary algorithms used for the deconvolution of the scattering data

- The orientation of non-spherical particles to the light source in the measurement cell

- Theory-based on particles only being spherical in nature

Incorporating Dynamic Image analysis and directly integrating it within sizing workflow allows a user to capture important shape information and provides an orthogonal technique for validating the sizing data. Using this vital addition, the user of this integrated workflow is able to work with both eyes open when determining the shape and size data of their particles.

References and Further Reading

- Cho, Jaehun & Sohn, Hong Yong. (2016). Effects of particle shape and size distribution on the overall fluid-solid reaction rates of particle assemblages. The Canadian Journal of Chemical Engineering. 94. 10.1002/cjce.22533.

- Karthik G. M. and Vivek V. Buwa* Effect of Particle Shape on Catalyst Deactivation Using Particle Resolved CFD Simulations, ISCRE25, May 2018

- Meer Saiful Hassan, Raymond Wai Man Lau. Effect of Particle Shape on Dry Particle Inhalation: Study of Flowability, Aerosolization, and Deposition Properties AAPS PharmSciTech. 2009 Dec; 10(4): 1252. Published online 2009 Oct 29. doi: 10.1208/s12249-009-9313-

- Hlosta, Jakub & Žurovec, David & Jezerská, Lucie & Zegzulka, Jiří & Necas, Jan. (2016). Effect of Particle Shape and Size on the compressibility and bulk properties of powder, Powder Mettalurgy June 2016

- Jie Chen, Bipul Sarma, James M. B. Evans, and Allan S. Myerson, Pharmaceutical Crystallization, Crystal Growth & Design 2011 11 (4), 887-895 DOI: 10.1021/cg101556s

This information has been sourced, reviewed and adapted from materials provided by Vision Analytical Inc.

For more information on this source, please visit Vision Analytical Inc.