The pursuit of sustainability is often a challenge, especially for materials manufacturers. In this interview, Dr. Aphrodite explains the role that Goodfellow plays in this objective and introduces green graphene and the significance it can have in terms of sustainability.

What benefits and qualities does green graphene possess compared to graphene? Is it a superior product?

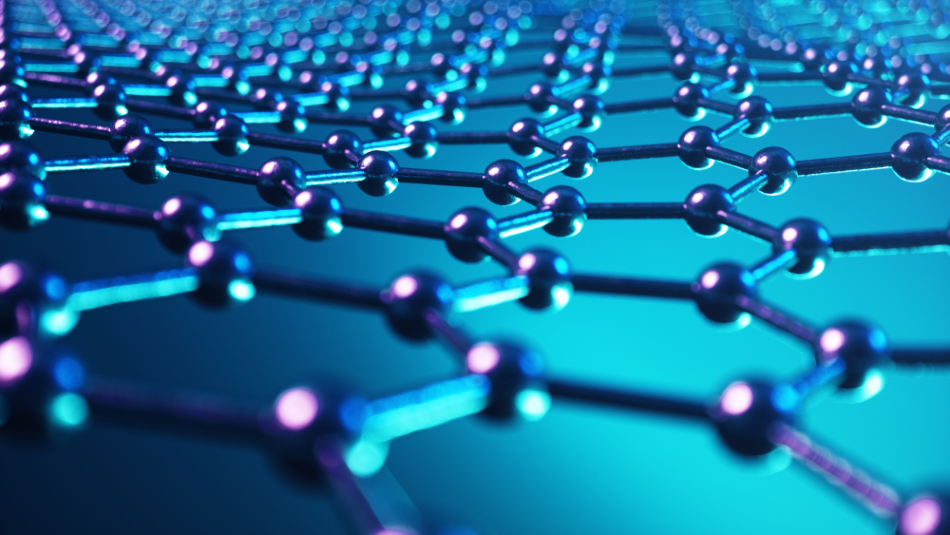

Green Graphene | The Pursuit of Sustainability and Innovation

Nowadays, researchers are looking, with great anticipation, into the potential provided by the mass production of green graphene and also of the improvement of its properties. Graphene can be produced through several methods, such as an exfoliation process, a reduced graphene oxide method, and also through chemical vapor deposition synthesis.

However, these methods have several critical bottlenecks, for example, in the cost of the production, the purity of the graphene, or even the scalability of the process. Recently, Goodfellow has introduced to the market an ultrapure green graphene, which is guaranteed metal-free. This graphene doesn't include any surfactants or chemicals, any additives, or even metal impurities from the catalyst.

Please outline how green graphene is produced. How does the process differ from traditional graphene?

Green graphene is produced by a highly scalable process that includes the decomposition of methane. Methane is a potent greenhouse gas derived by several processes and it is a harmful by-product. These processes can include farming, landfills, or even palm oil milling.

Green graphene is produced in a plasma reactor where methane is introduced into the plasma reactor and it decomposes to elemental carbon and hydrogen. Afterwards, the elemental carbon combines into graphene layers into the hydrogen atmosphere.

The elapsed time of this process, from the introduction of the methane gas into the plasma reactor chamber to the formation of graphene layers, takes almost one second. Proprietary heat treatment then takes place and results in the formation of predominantly one-layer graphene.

The graphene layers that are produced through this process are very thin and slightly scrambled. They also do not stack. This is not happening during an exfoliation processes. For that reason, we can understand the importance of this material. The performance of this graphene is optimum, along with the benefits it offers electrical, thermal and mechanical properties.

Image Credit:Shutterstock/Rost9

How is Goodfellow helping bridge the gaps between the research lab and green graphene applications? What are some of the applications that will see the benefits of green graphene?

We have measured the surface area of the green graphene with the BET method and it has been proven to be over 300 times better than the graphite powder surface area. This green production method of graphene guarantees an ultrapure metal-free graphene.

This green graphene doesn't contain any metal impurities or chemical surfactants, which makes it a great metal filler in metal composites, or polymers or coatings, or in conductive inks. It can even be used in drug delivery and other medical applications.

In addition, the speed and the cost effectiveness of this mass production method allows graphene to be used in a wide range of applications and industries.

As Goodfellow is the only supplier worldwide of this type of green graphene, our technical team has an in-depth knowledge of the material. The team is made up of the go-to experts for researchers if they need to investigate the potential of green graphene and its applications.

Sustainability is extremely important in today’s world and especially important when it comes to the development of materials. What role will green graphene play in the future of materials technology?

The ability of the green mass production method has the potential to reduce the price of the graphene in the market. As a result of this reduction in price, we can see the graphene being used in different applications, in applications that we have never dreamed of, which extends to the explosion of this research area as well.

In addition, using greenhouse gas methane means we are aiming for sustainability by using these gases for a better future outcome. Goodfellow's high-priority objective is to provide to our customers green materials, or materials that are derived from green methods of production.

These materials will promote environmental awareness and they can be used for the general good.

About Dr. Aphrodite Tomou

Aphrodite is the Technical Manager of Goodfellow Cambridge Ltd, a leading global supplier of materials for research, innovation and development in science and industry sectors. Goodfellow has an extensive range of products, which are monitored and enhanced by Aphrodite and her team. Aphrodite has a diverse background and wide-ranging knowledge of materials, from nanomaterials to metals, ceramics and glass.

She holds a PhD and Masters in materials science and engineering, has published several papers in peer-reviewed international journals, and presented at international conferences as an invited speaker. Her team consists of scientists and engineers having expertise in various material areas and processes. Together, Aphrodite and the Technical team assist researchers and engineers, on a day-to-day basis, in finding solutions to even the most challenging of research problems.

About Goodfellow

Goodfellow supplies metals, ceramics and other materials to meet the research, development and specialist production requirements of science and industry worldwide.

The Goodfellow group consists of four companies. The main administration, research laboratories and workshops are located at the Company's headquarters in Cambridge, England. The subsidiary offices in America, France and Germany provide an additional service.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.