In this interview, AZoM talks to Martin Thomas, lead scientist at Anton Paar QuantaTec about Fuel Cell and Battery research and how Anton Paar plays a part in said research

Can you give a brief overview of Anton Paar and the work you do?

Anton Paar was established in 1922 as a one-man locksmith’s workshop. Today, over 3400 employees in 110 countries develop, produce and distribute highly accurate laboratory instruments and process measuring systems, and provide custom-tailored automation and robotic solutions. Today Anton Paar is the world market leader in the measurement of density and concentration, the determination of dissolved carbon dioxide, and in the fields of rheometry and viscometry. I am the lead scientist at Anton Paar QuantaTec – the porous materials characterization unit of Anton Paar. I provide relevant and expert level scientific education and support to customers and also collaborate with various departments within Anton Paar such as R&D and product specialists.

How are the physicochemical properties of active components important to fuel cell performance?

Fuel cells must react energy-rich fuel such as hydrogen with, in this case, an oxidizer such as oxygen from the air. To do this efficiently without actually burning them together a catalyst is employed whose active surface area determines how many reactions can be catalyzed in a given amount of time in a given package size. And the gas diffusion layer in this particular type of fuel cell has to have optimal permeability to the gases without flooding with the product of this reaction, water. So properties like particle size and density determine how these materials can be laid down together with conductive carbon in thin films, hopefully with the correct pore size distribution and porosity, while maintaining accessible surface area.

How can Anton Paar assist in determining the physicochemical properties of active components?

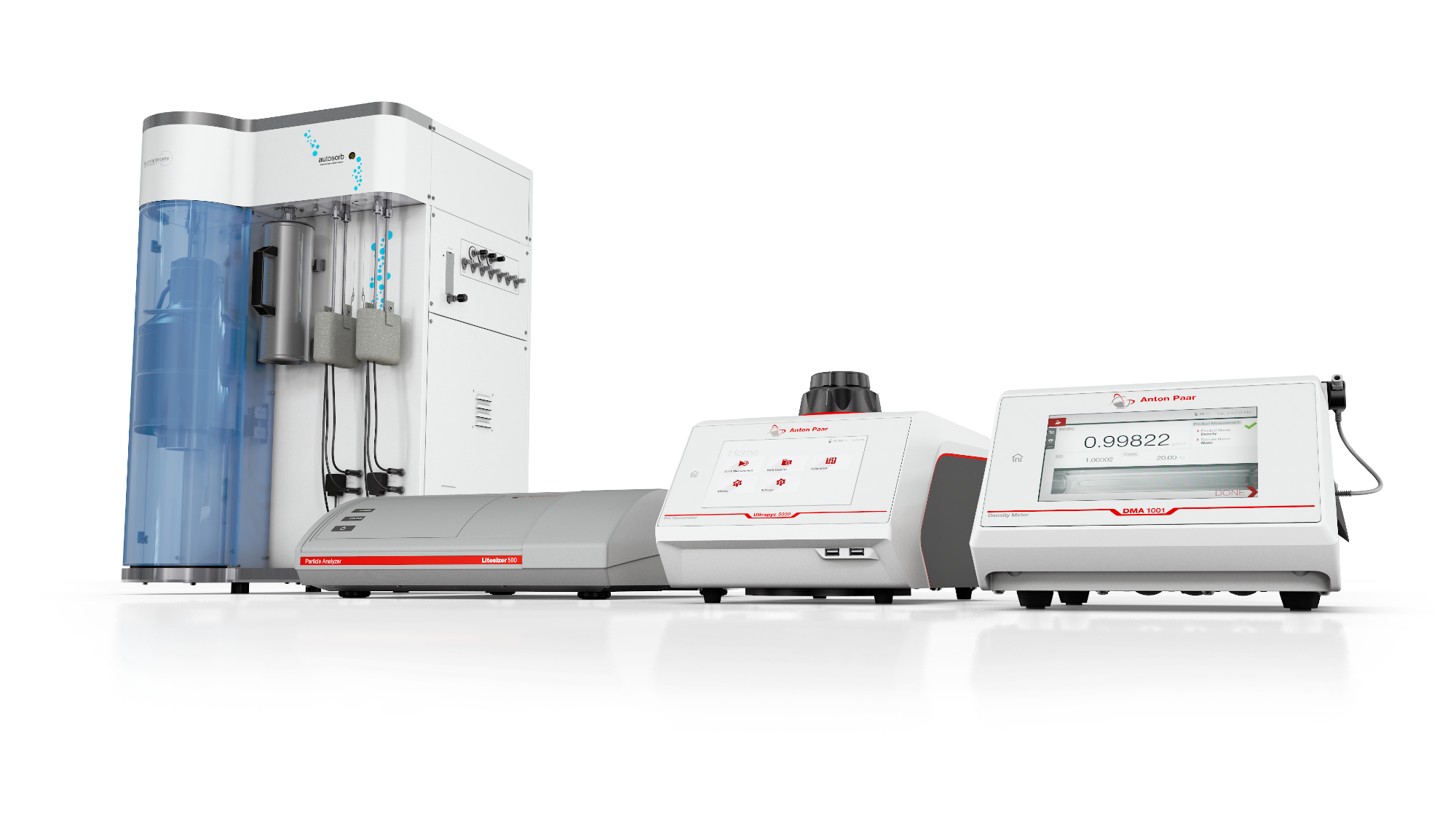

For both fuel cells and batteries, Anton Paar has a unique product portfolio that includes products suitable both for R&D and manufacturing quality. That affects those responsible for raw materials production, such as lithium metal oxides and separators for example, and those responsible for the various fabrication steps like slurry preparation, coating, drying, and calendering. To these ends, our products can determine surface area, particle size, density, porosity, pore size, hydrophilicity/phobicity, and zeta potential for both slurry stability and for membrane surface charge, even surface roughness and scratch-resistance of coated foils.

How is this different from achieving the highest quality lithium-ion batteries?

It’s basically one and the same thing. The amount of charge that can be stored and how quickly that charge as electrons can move in and out of the cell, and across the cell as ions, are directly correlated with true and skeletal density of the components, particle size and packing density, and surface area which, don’t forget which is where all the action takes place, that is the exchange of electrons and ions between electrode solids and electrolyte occurs. Ensuring that only in-specification materials enter the battery manufacturing process guarantees a quality end product when the various fabrication steps are running as they should.

Which Anton Paar products are ideal for lithium-ion battery research?

The Autosorb iQ is a gas sorption analyzer that can handle all types of battery powders, from very low surface area to very high surface area, and is even available with water vapor sorption capability too. The NOVAtouch is a high throughput gas sorption analyzer ideal for screening a lot of samples that are not so low in surface area as to require the use of krypton gas (for which the Autosorb iQ is ideal). True and skeletal density requirements are satisfied by the Ultrapyc 5000 gas pycnometer which includes the PowderProtect design feature to eliminate the elutriation of fine powders into the instrument, and built-in Peltier temperature control. Tap density of powders and powder blends is easily characterized which is an ideal follow up to particle size distributions of powders done on the PSA laser diffraction analyzer which can run with dry powders or powders suspended in a suitable liquid, and/or the Litesizer instrument for particles in the nano range which can also yield important zeta potential values essential for understanding particle dispersion behavior in liquids. Separator design can be optimized by knowing the pore size distribution determined on the Porometer 3G capillary flow porometer and surface charge characteristics investigated using the SurPASS surface zeta potential analyzer.

What are the drawbacks of using traditional concentration measurement methods in lead-acid batteries?

Hydrometers are used to measure the concentration of sulphuric acid in a conventional way. They might be well-known but have one big issue: the incorrect measurement reading from the scale. It is not as accurate as a digital hydrometer - the handheld density meter from Anton Paar. Additionally, there is no option to document the reading in a reliable and fail-safe way. A manual temperature correction is needed to get the correct measurement reading.

How does a digital hydrometer overcome these issues?

Digital hydrometers from Anton Paar provide high accuracy and repeatability. The readings are digitally shown on the instrument and can be simply transmitted to a computer via contactless interfaces which best supports the traceability of the measurements. With stored temperature correction tables in the instrument, the accurate measurement result is provided and there is no correction needed, eliminating additional steps for the user.

How are Anton Paar products superior to other products on the market?

Over 3400 employees between the headquarters in Graz, eight other producing subsidiaries, and 32 sales subsidiaries worldwide ensure that Anton Paar products live up to their excellent reputation. The core competence of Anton Paar – high-precision production – and close contact to the scientific community form the basis for the quality of Anton Paar’s instruments. The products are backed by a three-year warranty as standard and supported by a worldwide network of service teams, product, and application specialists.

What are the additional benefits of working with Anton Paar in the field of batteries research?

Anton Paar offers a unique range of products, not just those I mentioned earlier. So if there are even broader aspects to a specific battery research program, Anton Paar has solutions for rheology, viscosity, surface topography - via AFM - structural studies with SAXS and accessories for X-ray diffraction and so on. Anton Paar products are used not just in the field of lithium-ion, but also in more traditional lead-acid secondary cells, primary batteries, and even supercapacitors.

Where do you think the battery and fuel cell industry is heading in the future? Do you see any trends and developments coming?

The challenges that continue to drive development in batteries are in energy density, both in terms of weight -for example, less mass means better range in an electric vehicle, and volume - for example, more content streaming on-the-go in a comfortably sized mobile phone. New materials will be increasingly used such as silicon and nickel with reduced dependency on lithium and cobalt, plus improvements in the ability to recycle battery materials in the non-lead acid arena… lead-acid cells are already effectively recycled. Separator efficiency and thermal performance are critical when it comes to battery safety – and this component will see further improvement efforts. Fuel cells seem headed toward greater viability in the heavy vehicle sector where the weight of fuel is consumed which adds to the range, plus relatively quick re-fuelling en route… though of course, that infrastructure lags behind electric charging points!

About the Researcher

Dr. Martin Thomas has more than thirty-seven years of industrial experience in the characterization of porous materials and powders since his Ph.D. studies (University of Birmingham, UK) relating to the nickel hydroxide electrode (one half of a nickel-cadmium cell). He was a Research Investigator with Cookson group (now Vesuvius plc) then at ICI’s Catalyst Research center (now a Johnson Matthey facility) as a Principal Research Officer before joining Quantachrome Instruments (now Anton Paar QuantaTec) in 1991. He is a co-inventor of eight published patents relating to porous materials and their characterization, and is co-author of “Characterization of Porous Solids and Powders: Surface Area, Porosity and Density, S. Lowell, J. Shields, M.A. Thomas & M. Thommes” published by Springer.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.