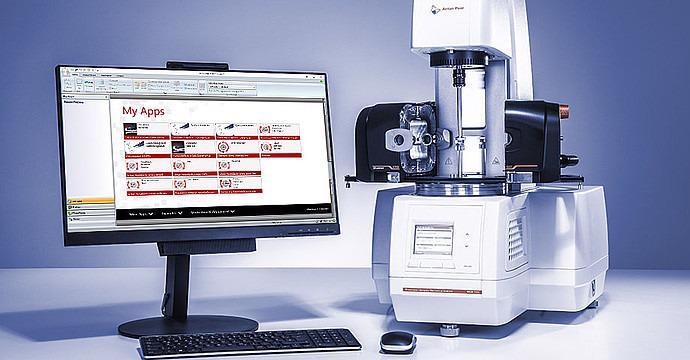

The new MCR Evolution series is an outcome of consistent thinking and rethinking of progressive designing with decades of experience and the feedback received from more than 10,000 satisfied customers. The combination of innovative and thousandfold field-proven technology with the modular design showcases the milestone on its series.

Thanks to its 200+ accessories, the MCR Evolution rheometer series offers endless possibilities for rheological investigations and material characterization. The system enables performing complicated unmatched rheological research and advanced QC testing.

MCR 102e

- Built on EC motor technology with 25 years of experience and market leadership with a torque ranging from 2 nNm to 200 mNm

- Capable of doing normal force measurement up to 50 N

- Best way to perform QC testing and rheological product development, upgradeable with sample-adaptive controllers

MCR 302e

- The system is a reference EC motor on the market with a torque range of 0.5 to 230 mNm and combined active thermal management

- This is the next milestone of the world’s most-sold rheometer for improved QC testing and rheological research

- Available with more space for sample handling and exchange of accessories

MCR 502e Power

- A robust rheometer model for special applications

- Active thermal management of motor and bearing for long-term measurements even at high torques

- Distinctive maximum torque of 300 mNm and normal force of 70 N specifications

Key Features

The Best now Better: the New MCR Evolution Series

Anton Paar had consistently worked for more than 25 years to extend the portfolio in close association with the customers and rheometer users. The company takes the privilege to launch the new MCR Evolution series. These are the rheometers that help to progress to the next level.

The Benefits of the New MCR Evolution Series

- The quick one-hand coupling and decoupling of calculating geometries in a second, even at extreme temperatures ranging at −160°C to 1000°C, is a novel quick-connect mechanism

- Delivers stable results even for long-term measurements with low torque, offering improved thermal management within the EC motor starting from MCR 302e

- Enables accurate measurement of low-viscosity samples even with the entry budget model with a higher sensitivity ranging from 7.5 nMm to 2 nNm

- This is the only commercially available device with a trimming mirror of 360° view of the sample with no blind spots, eliminating sample preparation errors and resulting in high reproducibility outcomes

- Ability to detect any sample behavior change even at the shortest time scale with a reproducible time of each measuring point ranging down to 1 ms

- Additional space for sample handling and exchange of accessories with an extended working height starting from MCR 302e

- Full pharma compliance: The best pharma package for the RheoCompass software (21 CFR Part 11, full data integrity according to ALCOA+)

Image Credit: Anton Paar GmbH

Takes Work off the Hands: Unique Motor and Sample-Adaptive Controller Technology

The MCR Evo series is a result of 25 years of research, development and constant improvement. Technology has enhanced the capability of rheometry.

The combination of the EC motor (Permanent Magnet Synchronous Motor) using a high-accuracy air bearing with active thermal management, integrated normal force sensor and a high-resolution optical encoder enables rheological measurements even at the lowest torque range.

The exclusive sample-adaptive controllers for measurement in rotation (TruRate™) and oscillation (TruStrain™) work for 99% of all samples and measurements “out of the box” with an ideal combination of speed and precision. This saves time and workload and provides better data in parallel.

Image Credit: Anton Paar GmbH

Excellence in Every Component and Every Work Step

With decades of experience in the field, Anton Paar understands and predicts the requirement for high-performance rheological analysis. With this knowledge, the company has designed each component and developed every handling step to be a part of a smooth and intelligent device.

- Enables single-handed exchange of measuring systems due to the QuickConnect coupling

- The patented Toolmaster™ technology is capable of automatically recognizing measuring systems

- The TruGap™ feature detects the real measuring gap

- T-Ready™ is capable of detecting sample temperature equilibration in real-time

- The trimming mirror offers a 360° view of the sample and facilitates high measurement repeatability and many more features

Image Credit: Anton Paar GmbH

Choose from More than 100 Test Templates, Set Report Filters and Use Remote Control

The intuitive RheoCompass software provides predefined and customized test templates and analysis definitions. Additionally, it is possible to export the rheological information and generate reports, and data can be filtered, for example, by year, batch number or operator, and is displayed within seconds.

Thanks to the Ethernet connection, the rheometer can be remote-controlled from anywhere through the company network. Gap setting, adjustments and tests can be started directly from the MCR rheometer. This reduces annoying switches between the computer and the device, for example, during sample preparation.

Image Credit: Anton Paar GmbH

Unlimited Possibilities: Add One of More than 200 Accessories

Anton Paar rheometers are quick and simple to adapt to the current and future rheological requirements. The flexibility makes them the most favored instruments in scientific publications on rheological analysis.

An extensive range of application-specific accessories is available to increase the capabilities of the rheometer, including DMA measurements, extensional rheology, rheo-optics (e.g. microscopy and Raman spectroscopy), magneto- and electrorheology, dielectric spectroscopy, interfacial rheology, UV curing, pressure- and humidity-dependent rheology, tribology and many more.

A broad range of temperature accessories enables to application and control of temperatures ranging from −160 °C to 1000 °C.

Image Credit: Anton Paar GmbH

Your Partner for Special Applications and Customized Solutions

The special model MCR 502e Power provides the highest available torque of 300 mNm and the highest available normal force of 70 N at the reach of the user. This implies that the user can perform fatigue- and heating-controlled stress tests on asphalt mixtures.

Decades of experience in the field enable Anton Paar to perform all tasks seamlessly. The company develops and supplies customized products for all kinds of specific applications. The in-house production capability in Austria and a dedicated R&D team situated closely help develop and supply customized products for all kinds of specific applications.

Feel free to contact Anton Paar to discuss the requirements and to find a customized solution for the measurement task.

Image Credit: Anton Paar GmbH

Pushing the boundaries was a collaborative process. Real problems which affect society require multiple disciplines and engaged partners, and that’s what we get from Anton Paar.

Alan Rowan, Professor, University of Queensland, Australian Institute for Bioengineering and Nanotechnology