Pump clogs produce sanitary sewer overflows (SSOs) and backed up lift stations that harm the environment. Additionally, they risk public health and result in regulatory fines for the utility. Wastewater operators and lift station technicians are dedicated and on call 24/7 to react to emergencies. This response is frequently following an overflow and the issue is expensive, causing overtime and repair expenses.

The utility additionally is negatively perceived by the public it works for. A lot of utilities use non-clog pumps in their systems to minimize possible sewer overflows. Despite this, blockages and additional upkeep issues still arise.

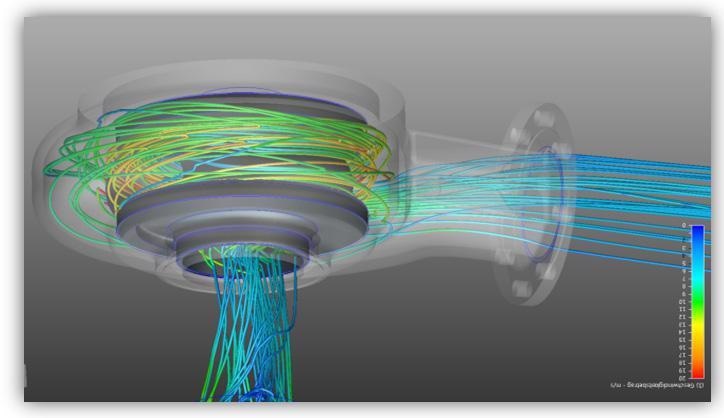

Image Credit: Homa Pump Technology

The Cause of Pump Clogging

Pumping technology and lift station design have both advanced throughout the years; however, pump clogs triggered by ragging have risen. This might appear counterintuitive, but multiple factors have caused this.

More Rag-Forming Material is Being Flushed

Many ‘flushable’ products are now accessible to the public. These comprise many wet wipes, paper towels, feminine hygiene products, baby diapers or liners, and toilet cleaning pads. Individuals additionally get rid of cooking grease by emptying it down the sink. Such materials may move through the toilet and a single service line; however, when in the sewer system, the combination of grease, hair, and the additional ‘flushable’ products causes stringy rag balls. These can become extremely large and long, growing into ‘pigtails’ or giant ‘fatbergs.’

Solid Material is More Concentrated in the Wastewater

Water utilities have observed a reduction in water usage. Utilities promote water conservation to safeguard declining freshwater resources. Public education establishes knowledge about the significance of reducing water use. Tiered conservation rates, where those who use a lot pay more than low users, promote conservation even further. New regulations need manufacturers to generate water-saving appliances, and plumbing codes support the use of low-flow toilets and showerheads.

Such endeavors have been effective in aiding the preservation of a valuable resource. However, in the sewer system, smaller amounts of water increase the comparative solids content of the pumped media allowing for rag balls to form more quickly and easily.

Non-Clog Pumps as a Solution

To minimize the possibility of clogging, engineers frequently identify pumps with non-clog impellers for sewage pump stations. Such impellers are created with a small number of vanes, at times just a single vane. The 10 States Standard stipulates that the pump needs to pass at least a 3” spherical solid. In principle, a pump employing this design should not clog.

Non-Clog Pumps in the Real World

Clogging and maintenance problems still occur, despite the installation of non-clog pumps.

Mechanical Issues

Rag balls and pigtails vary from dense spherical solids. Comprised of stringy, fibrous wastes, rags can hook on prominent edges of the impeller vanes in certain pumps. Rag balls then accumulate or are pulled into the impeller. This causes a thermal overload in which the pump trips off. The consequence is an SSO and a costly callout for the crew to pull the pump and get rid of the rags. If an SSO ensues, a call to the regulatory agency, cleanup, and mitigation is necessary. Additional O&M problems can be caused by pump and impeller design. Employing a semi-open impeller, large solids passing through the pump can hook on the prominent sides of the impeller. This can trigger shaft deflection, causing potential mechanical seal or bearing malfunction.

Semi-open impellers become less efficient over time as clearances alter across the vane and the volute. Frequent modification of the clearances is necessary to preserve effectiveness, but that seldom occurs in the wastewater world.

Image Credit: Homa Pump Technology

Procedural Issues

Problems are additionally triggered by procedural issues. For example, sewer clogs frequently take place in the sewer mains. When operators jet-clean the mains, the grease and rags are pushed downstream to the lift station. Rags then build up in the pump. Grease accumulation on the impeller can cause a disparity causing vibration and pump damage. Several utilities do not have existing programs to handle fat, oil, and grease (FOG) from restaurants and businesses. Not much is done to educate the public regarding issues created by wipes and further ‘flushables.’ As such, people persist in flushing such materials into the sewer system in which cause blockages.

Image Credit: Homa Pump Technology

Non-Clog Pump Solutions

Effective non-clog pump solutions are accessible. First, it is critical to employ the correct pump for the application. It must be ensured that the pump is correctly sized and created for the system traits. For sewage pumping, where rags and debris are expected to be an issue, pumps with a solitary vane enclosed impeller are optimal. If designed correctly, the shrouds on both ends of the impeller stop fibrous materials from hanging up in the pump. A single vane concave impeller design, like HOMA’s AMS Series, offers a broad flow region, permitting solids to flush through the pump.

Enclosed impellers additionally possess a wear ring that fixes into the volute, reducing the necessity for forthcoming clearance modifications. Enclosed impellers additionally stop shaft deflection and possible seal and bearing breakdowns. Standard operating procedures (SOPs) should be created for sewer cleaning. These should have a condition for vacuum excavation of rags, grease, and debris at a downstream manhole.

Vacuum excavation should take place prior to the debris arriving at the closest lift station. If possible, utilities should employ a FOG program to lessen the level of grease in the system. FOG programs possess identifying grease trap owners, performing inspections, and enforcing ordinances. Although such solutions appear practical, funding for further staff or equipment could be difficult to come by.

Acknowledgments

Produced from materials originally authored by Ray Warren Service/Quality Manager, HOMA Pump Technology.

This information has been sourced, reviewed and adapted from materials provided by Homa Pump Technology.

For more information on this source, please visit Homa Pump Technology.