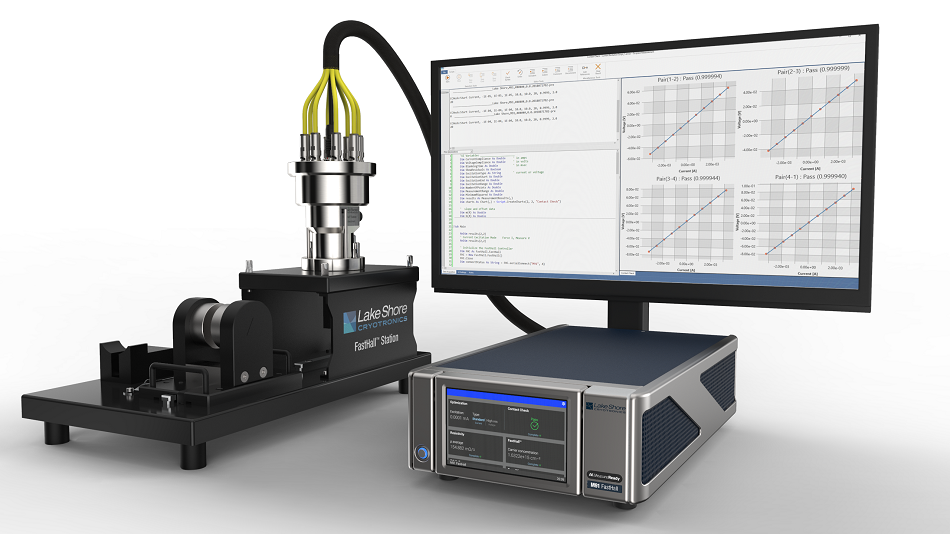

In this AZoM interview, Chuck Cimino, Senior Product Manager for Lake Shore Cryotronics, talks about their new product, the FastHall Station—a tabletop Hall effect analysis system that enables measurements to be made on low-mobility materials without field reversal in seconds.

Can you tell us about Lake Shore Cryotronics and the work you do?

We were founded in 1968 as a supplier of cryogenic temperature sensors, with our first sensors sold to Argonne National Lab, but the company expanded over the years to include systems and other products for scientists conducting early-stage electronic and magnetic material research. Researchers use our low-level characterization products as they develop novel materials for use in future technologies, and this work is expected to only increase as the scientific community aims to bring quantum computing devices and new nanomaterial-based technologies to market. As a product manager, I’m responsible for ensuring that our future systems and measurement products align with the evolving requirements of our user base and make their jobs easier.

The MeasureReady™ M91 FastHall™ Station is an integrated tabletop system for Hall effect material analysis. How does it make a wide range of measurements possible?

At the heart of the FastHall Station is our M91 FastHall measurement controller, a single instrument that replaces the various instruments and software one typically would need to make Hall measurements. This controller features our patented FastHall™ technology, which enhances testing speed. When compared with traditional Hall measurement methods, it can be as much as 100x faster, and this applies to materials that are more difficult to measure because of their high resistance properties or very low mobilities. This speed is a direct result of the M91 controller not having to perform field reversal to cancel thermal and misalignments errors, which allows for simpler magnet setups. As a result, analysis of a challenging sample that previously may not have been possible can now be done in just a few minutes using this fully integrated station. Along with the controller, the system includes a PC, a standard 1 T permanent magnet, a high-precision sample holder, and all the necessary software and cabling to begin running a series of measurements right out of the box. It truly shortens the time it takes to set up and execute an experiment, even for those who are new to performing Hall measurements. We have found that customers increasingly prefer testing solutions that are more readily accessible and usable by more broadly skilled users. We believe we’ve accomplished this with the FastHall Station while also improving the speed and consistency of the Hall measurement itself.

Could you tell our readers the main features and benefits of the MeasureReady FastHall Station?

The main feature and benefit of the station is, again, its speed and precision, especially for researchers who are studying new classes of photovoltaic structures and other low-mobility materials. For van der Pauw samples, it supports mobility measurements down to 0.01 cm2/V s, and the system allows for much faster characterization when compared with traditional AC and DC field Hall measurement techniques.

In addition, the system is designed to ensure higher quality measurements, especially with respect to leakage current, which can reduce the magnitude of the signal reaching the instrument’s measurement circuit, and particularly when sample resistivity is high. The use of completely guarded triaxial cabling to the sample chamber and guarded contacts on the chamber helps in this regard – in fact, we spec the system as supporting high resistance measurements up to 1 GΩ. So, what the user gets is a light-tight system with an electronically shielded, low-noise sample space that provides far superior measurements as compared to other comparable tabletop Hall measurement solutions available today.

Another benefit is that the station is easy to set up and run. It comes with solder and prober pin-style sample cards that can accommodate both van der Pauw and Hall bar type samples up to 10 × 10 mm in size, and allow you to mount your samples without having to solder contact pads. You simply load your sample and begin running measurements using the station’s MeasureLINK™-MCS application software, whether you’re looking to derive carrier type, carrier concentration, mobility, or Hall coefficient properties of a sample. Our application software automates the entire measurement sequence, collecting all the data. In addition to performing the complete Hall analysis and outputting the usual measured and derived mobility values, the system can also generate detailed reports including all the supporting intermediate data, so the researcher can confirm the integrity of the final results. It also offers user-customizable test scripts, so you can create your own test sequences.

How does the FastHall Station differ from other Hall Effect measurement solutions and similar products on the market as well as the MeasureReady™ M91 FastHall™ measurement controller itself?

For many researchers, their typical Hall solution is to assemble an array of various instruments to perform the measurements on a permanent magnet, an electromagnet, or superconducting magnet. In a typical lab setup, this is generally accomplished using a current source and voltmeter along with a signal switching unit to automatically measure sample resistivity and Hall voltages, plus a holder or fixture of some type to mount the sample material. However, after doing all this work to assemble, cable, and program the different instruments, you still need to obtain or create some level of specialized software to correctly control the equipment, acquire the measurement data, and perform all the proper pre- and post-measurement calculations to derive the material parameters desired. For these reasons, some researchers prefer to purchase a prepackaged system, whether a tabletop or a larger, more capability-rich electromagnet-based Hall system. But even going that route, one would still lack the measurement speed and capabilities of the M91 measurement controller and its turnkey software for automating the entire Hall measurement process.

So, if you want to benefit from our patented FastHall technology and your lab is already equipped with a magnet and some sort of benchtop holder for the sample, then the M91 controller may be all you need. But what if you don’t have a magnet and don’t want to deal with any of the sample fixturing and cabling? Then the FastHall Station is the way to go. It pre-packages everything you need as a complete out-of-the-box solution and, therefore, requires much less experimental setup. It is truly a turnkey solution for researchers who are looking to derive key parameters of semiconductor materials – and do so more quickly without any complicated equipment setup.

Also worth mentioning is, as standard, the tabletop station supports room temperature measurements. However, to convert it to a cryogenically cooled sample space, an LN2 option can be optionally specified. This way, Hall analysis measurements as a function of low temperature can be performed while the sample is in a flooded liquid nitrogen bath. And for researchers who want to conduct Hall measurements with a gate bias applied, we also offer a gate bias option that includes a low-noise DC current/voltage source instrument.

The FastHall Station combines all the necessary Hall measurement system functions in a tabletop package, automating and optimizing the measurement process, and directly reporting the desired parameters. What applications will benefit from the station?

Yes, the station’s M91 instrument includes all the firmware needed to execute the entire Hall measurement process, collect the data, and calculate the final Hall and mobility parameters. The instrument needs no manual setup and outputs Hall measurement results directly without using PC software for the calculations. In addition, because the software provides the researcher with the ability to double-check the intermediate results of the analysis, there’s much less chance of being misled as to the validity of the reported results. And because of its ability to provide researchers with rather detailed results – and much better results, at that – in minutes versus hours, it’s especially beneficial to researchers who are measuring low-mobility materials, such as organic semiconductors and photovoltaics, where previously only AC field techniques were viable. We also expect to see the low-mobility measurement capabilities in demand by anyone studying various nano, spintronics, and other emergent materials and devices. It’s also an ideal Hall measurement solution for characterizing transparent conducting oxides, III-V and II-VI semiconductors, topical insulators, TMDs, and a host of other 2D materials.

What is the future for Lake Shore Cryotronics?

Much of our future solution-level product development centers around the MeasureLINK software included with the tabletop Hall station. The software will be common to all new material characterization products introduced, and it’s designed to coordinate with variable temperatures and/or variable magnetic field controllers found on common research platforms – such as cryogenic probe stations and high-field superconducting magnet systems. This way, the user can enable fully automated variable temperature/variable field Hall measurement from a single common interface. Plus, the software uses industry-standard protocols and integrates easily with supervisory packages such as LabVIEW™ to the extent needed for each experiment. And, looking ahead, we expect the software to improve with future releases. It already comes with preprogrammed Hall measurement sequences and scripts, but additional scripts will continually be added, and users can also create entirely new ones to accommodate custom measurement protocols. They also have the option to order our application packs that extend the functionality of the base MeasureLINK software. These packs include the drivers needed to communicate with the instruments, scripts to run all the Hall measurements, and additional utilities for reporting the results of the measurements.

I should also note that with Lake Shore’s recent acquisition of the lab cryogenics business from Janis, we will be able to offer a more complete portfolio of cryogenic and measurement product combination solutions going forward. There are many synergistic product opportunities ahead where we’ll be able to combine Lake Shore’s expertise in instrumentation, applications, and system engineering with Janis' strength in cryogenic system design and fabrication, so stay tuned!

Where can our readers go to find out more?

Just go to lakeshore.com and follow the link on the homepage to our Hall Effect Measurement Systems product landing page and look for FastHall Station, or just go to lakeshore.com/FHS.

About Chuck Cimino

Chuck Cimino has more than 30 years’ experience in the global test and measurement industry. Before joining Lake Shore Cryotronics in 2018, he held various leadership roles at Keithley Instruments, including Senior Marketing Director of Semiconductor I-V Instruments. As a Senior Product Manager for Lake Shore, Chuck manages product marketing for the company’s line of MeasureReady test and measurement instruments, Hall effect measurement systems, vibrating sample magnetometers, and various other systems designed for low-level material research.

Chuck Cimino has more than 30 years’ experience in the global test and measurement industry. Before joining Lake Shore Cryotronics in 2018, he held various leadership roles at Keithley Instruments, including Senior Marketing Director of Semiconductor I-V Instruments. As a Senior Product Manager for Lake Shore, Chuck manages product marketing for the company’s line of MeasureReady test and measurement instruments, Hall effect measurement systems, vibrating sample magnetometers, and various other systems designed for low-level material research.

Chuck’s undergraduate degree is in Applied Electrical Engineering, and he has an MBA from Case Western Reserve University with a concentration on leadership, finance, and entrepreneurialism.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.