Why is the availability of helium becoming a pressing concern for research labs, and what unique challenges does it pose?

The high cost of helium is a big issue most researchers face, especially if they’re involved in early-stage material research and need to go to temperatures lower than what liquid nitrogen offers. It’s particularly challenging for smaller labs or institutions who don’t have a large budget or cannot benefit from the cost savings afforded by ordering larger quantities of helium on a regular basis. Without a reliable source and having to always pay more for cryogens means you can’t do all the work required in a certain amount of time, directly impacting scientific progress.

Image Credit: Lake Shore Cryotronics Inc.

Could you shed light on the factors that drive up the cost of helium in research environments and the strategies labs have been employing to address this issue?

Helium is a non-renewable resource, and once released into the atmosphere, it’s nearly impossible to recapture — it just escapes into space. Plus, extracting helium is a complex and expensive process. It is usually found in small quantities mixed with natural gas, and separating helium requires sophisticated equipment and expensive processes. Plus, the demand for helium has also been rising in various industries, and this growing demand puts pressure on the limited supply. What’s more, most of the world's helium supply comes from a small number of sources. So to deal with the costs, scientists who require cryogens for the type of research they’re doing have had to take some different approaches. In some cases, to reduce the impact, large universities are operating centralized helium recovery and liquefaction plants. But for most organizations, reducing costs and conserving helium for critical research is still an ongoing problem. For this reason, many have explored investing in various technologies that will enable them to better deal with the problem in the long term. Here at Lake Shore, we’ve made our own investments to both aid the company in our own cryogenic processes, such as converting our temperature sensor calibration stations to cryogen-free, and to provide a wide range of product solutions to also help researchers deal with the costs.

Can you elaborate on the measures, such as centralized helium recovery, that organizations have taken to combat the helium shortage?

A helium reclamation system can be installed, but because these systems are expensive, they’re commonly used in industries where large quantities of liquid helium are used, such as MRI manufacturing and larger research facilities with many labs. But if that’s something that interests you, I recommend consulting with experts or companies specialized in gas reclamation. They’ll be able to provide further insights and options tailored to one’s specific needs. However, for many labs, investing in cryogen-free equipment only where it is most needed may be the more budget-friendly option.

To address high helium costs, what initial steps do you recommend for organizations, particularly larger ones, to assess and mitigate helium usage?

For many organizations and companies, finding ways to mitigate the high costs should begin with an audit. This way, even if one does not take the next step to invest in new equipment, they have some idea relating to usage and they can also implement strategies to conserve one’s existing supplies. This audit would include determining the amount of helium used, the frequency, costs, and any patterns in consumption, and seeing where it might be wasted and where one might need to fix any leaks in storage tanks or distribution systems, seeing if there are any operational inefficiencies contributing to the excessive consumption of helium, and pinpointing where some of the excessive use and inefficiencies are most occurring. Then from there, a technological solution can be pursued, if warranted.

For smaller labs with budget constraints, what are some practical options for reducing helium consumption?

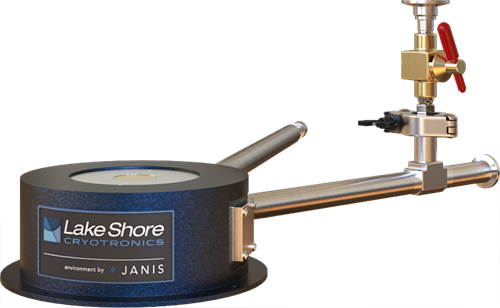

Some smaller labs — for example, those that focus on material or device characterization — may find that on-wafer measurements and experiments performed as a function of variable temperatures might be the only times where liquid cryogens are required. For them, a closed-cycle refrigerator-based cryogenic probe station may be all that they need. These CCR-based systems can be a big help, and even though the initial purchase price is a bit higher, they pay for themselves over time. Lake Shore has offered these cryogen-free stations for more than a decade, and we also offer upgrade kits for converting existing “wet” liquid cryogen probe stations to “dry” cryogen-free systems. Similar to this, we offer CCR-based cryostats for other applications. With the simplest models, the cryocooler is mounted onto the cryostat. They are a more general-purpose solution for making cryogenic measurements without using liquid helium, with models available for a sample in vacuum or sample in exchange gas.

Image Credit: Lake Shore Cryotronics Inc.

With Lake Shore Cryotronics’ 2020 acquisition of Janis Research’s lab cryogenics business, how did this move enhance the company's product offerings in general and also as it relates to helium-saving technologies?

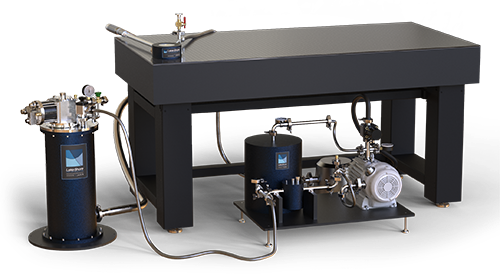

With the acquisition, the company is able to offer a much wider portfolio of products for researchers working at cryogenic temperatures. Lake Shore already offered cryogenic temperature sensors, controllers, and monitors, plus a number of systems and instruments for performing measurements at variable temperatures. But with the acquisition of Janis’s cryostat and cryocooler business, Lake Shore is able to offer the cryogenic environment itself as well as more solutions for cryogen-free operation. Among these are our recirculating gas coolers, or RGCs as we call them. These systems enable a continuous-flow cryostat to operate cryogen-free. They work by capturing the evaporated gas through the transfer line, reliquefying it, and continuously recirculating the helium to cool a sample that is mounted in a cryostat. What’s nice is, samples can be changed without warming up the RGC, allowing fast turnaround times. And because the system is off to the side of the cryostat, vibration is much less of an issue. For this reason, it’s a popular solution for microscopy applications where you don’t want equipment vibration to affect an experiment, which can happen with a cryogen-free CCR-based solution.

Could you share specific instances where researchers have found RGC solutions valuable, especially in experiments sensitive to vibrations?

Primarily, RGCs are valuable to users who love their existing continuous-flow cryostats and want a way to keep using them and not have to constantly deal with issues relating to helium supply. These cryostats are popular with a lot of users because they’re typically very compact and offer a lot of flexibility. For instance, with our ST-500 and ST-400 cryostats, you can run them sideways, you can run them vertically, and they fit into small spaces. The ST-500 is also an optical cryostat that is specifically designed for low vibration at the sample area, so it's often used by researchers doing microscopy measurements. And with the ST-400, we have a lot of scientists using this cryostat to cool samples in UHV environments. In these types of environments, they often put these cryostats on a manipulator and rotate them within an ultra-high-vacuum chamber. We see this being done in a lot of beamline applications and in large national lab facilities. But larger facilities also see the value of having an RGC for other reasons, too. Interested in saving costs on helium, these facilities tend to have helium liquifiers, but individual scientists are still interested in having “personal” liquifiers, so to speak, where they’re liquifying on the spot because the demand for helium is so high across the entire facility. We had one facility tell us they had trouble sourcing the helium gas they needed to keep the liquefier running and overcoming losses through leaks in the huge miles and miles of piping they have in the recovery system. So, in this instance, the large facility was interested in having RGCs so their users could do their low-temperature experiments where they want when they want and without having to be concerned with overall supply issues. And we also have a few other niche applications, such as NMR or FTIR spectroscopy applications, where the vibration isolation provided by the RGC system when used with a continuous-flow type of cryostat is really beneficial.

Image Credit: Lake Shore Cryotronics Inc.

When it comes to integrating RGCs into existing lab setups, how straightforward is the process, and what are the key differences compared to switching to a CCR-based solution?

The beauty of the RGC is the same RGC can be used with a wide range of cryostats. That means it lends itself well to all kinds of applications. And we designed it specifically so that people who already have a continuous-flow cryostat could use it in their existing setup. You may have a customer who has gone through all the trouble of setting up an experiment, and they love it and it’s working, but — oh my goodness — they’re now having a really hard time getting a hold of helium and what to do? Well, they could buy a whole new closed-cycle system and redo their experiment completely, or they can leave everything as is and just take the helium transfer line away and plug in an RGC. What’s not to love?

Also, in the case of older CCR-based technologies, hefting around a cryocooler-based system can be difficult, whereas if an RGC is sitting there off to the side doing its thing, and the cryostat is the only thing taking up space on an optical table in an experiment, then it is much more convenient to use and makes for a better setup. All the vibrating, noisy components are off to the side, resulting in low, nanometer-level vibration in an experiment, and they still get to use their continuous-flow cryostat and run it in any orientation they want.

Of course, there are customers who are just doing some general-purpose experiments, and they don’t care much about vibration. They just want to get a sample cold. Then a CCS system is a perfectly fine alternative. It’s cryogen free, it’s not too bulky, and it works quite well. And even if they do care some about vibration, then the middle ground option is a vibration-isolated closed-cycle system, which we also offer as an option. That’s perfectly fine for a lot of users.

Image Credit: Lake Shore Cryotronics Inc.

Looking ahead, what developments can we anticipate from Lake Shore Cryotronics in terms of helium-saving technologies?

We’re focused on making a number of improvements to our cryogen-free products and, right now, we’re in the process of introducing a new recirculating cooler system called Infinite Helium, which we previewed in November at the 2023 MRS Fall Meeting in Boston. What’s nice about this new system is it automates a lot of the setup and operation steps of such systems. There’s no more having to adjust valves and constantly keep an eye on cooldown operations. It offers single-button control and automatically determines optimum settings for best cooling power and base temperature, taking away all the guesswork. In addition, Infinite Helium guards against thermal-induced changes and thermal drift, providing you with very stable temperatures and a very stable experimental environment, which is beneficial when working with sensitive samples. Also, samples can be exchanged easily without warming up the system, allowing for fast turnaround times. And it’s designed to operate for extended periods — up to 6 months or longer — without any servicing required. In comparison, other solutions may need to be serviced as often as every couple of weeks. Plus, we’ve made further improvements in terms of vibration for researchers who need it for microscopy. All in all, we’re quite excited about this new system and what it offers the cryogenic research community in terms of both performance and ease of use.

Separate from that, we’re also focused on developing more fully integrated systems for measurements performed within a cryostat and making improvements to our software. With nearly every new release of our MeasureLINK™ software, our users gain more control over additional aspects of their low-temperature experiments, and this will certainly continue as the software is optimized for use with Infinite Helium and our other cryogen-free technologies.

About Rachael Floyd

Rachael Floyd, Director of Product Management for Cryogenic Systems at Lake Shore Cryotronics, has more than 20 years of experience developing standard, semi‐standard, and custom cryogenic products for the worldwide scientific community. She received her BSc (Hons) in Physics from the University of Canterbury in 1995 and her PhD in Engineering Physics from the University of Wollongong in 2000 and did postdoctoral work at the State University of New York at Buffalo. With Lake Shore, Rachael oversees all technical product management related to cryostats, cryocoolers, recirculating gas coolers, and other lab cooling products. In addition to working with customers to determine the correct product configuration for their application, she has been involved in specifying products for large scientific research projects, including the customization of cryostats for neutron scattering facilities.

This information has been sourced, reviewed and adapted from materials provided by Lake Shore Cryotronics Inc.

For more information on this source, please visit Lake Shore Cryotronics Inc.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.