In this AZoMaterials interview, Nadia Dugan, Product Marketer for Lake Shore Cryotronics, discusses new fully integrated material characterization and cryogenic test environment solutions for material research available from her company.

Can you tell us a little about Lake Shore Cryotronics and give some background that led up to this new capability offered by the company?

We started in 1968 as a supplier of cryogenic sensors, and then we expanded to temperature measurement instruments and later to system products in the 1970s. These systems are typically used by researchers studying the fundamental properties of novel electronic and magnetic materials. As certain behaviors can only be observed by cooling material to very low temperatures, we offer platforms such as our cryogenic probe stations that contain thermally insulated, cryogen-refrigerated vacuum chambers. Samples can be measured inside these as a function of temperature. Other systems, such as our Hall measurement systems and our vibrating sample magnetometers, can be specified with low-temperature measurement options.

Approximately five years ago, Lake Shore Cryotronics introduced a line of precision instruments specifically targeted at low-noise research applications for precise material characterization measurements. These MeasureReady® instruments were the products I was most involved with as an engineer, particularly our FastHall™ measurement instruments.

Lake Shore Cryotronics' most recent MeasureReady product, the M81 system, is designed for synchronous DC and AC lock-in applications requiring low-level measurements for material characterization. Up until 2020, the types of products the company was best known for were cryogenic sensors and instruments, systems and platforms for material characterization, gaussmeters, teslameters, and other instruments for magnetic field measurement and control.

In 2020, Lake Shore Cryotronics acquired the lab cryogenics business of Janis Research. Why was this significant?

This acquisition united two leading cryogenic and material characterization solutions providers for low-temperature research, with more than 50 years of experience supporting the worldwide physics and material research community.

It combined Lake Shore’s expertise in instrumentation, applications, and system engineering with Janis Research's strengths in designing and fabricating cryogenic systems. Together, the companies offer a more complete portfolio of product solutions. The cryostats developed by Janis Research enable us to offer a much more complete solution, one that is fully integrated to include the measurement electronics, the instrumentation and sensors for temperature control, and the cooling environment itself – all supported by a team of application scientists and engineers to help users along the way.

Cryostats expand the scientific solutions we can offer. Cryostats have many uses in the lab and measurement applications, such as those for FTIR, ESR, or NMR spectroscopy. They are also used in microscopy experiments involving imaging, high spatial resolution photoluminescence measurements, or for insertion into larger experimental apparatus, such as those built by labs for trapped ion studies or cold atom quantum simulation experiments performed at cryogenic temperatures under ultra-high vacuum.

A Lake Shore cryostat, the VNF-100 liquid nitrogen model that offers 65 K to 325 K operating temperatures. Image Credit: Lake Shore Cryotronics Inc.

The cooling systems can now be easily integrated into a setup with a MeasureReady instrument or a cryogenic probe station for material characterization. The entire platform is controlled using Lake Shore's MeasureLINK™ software.

To sum it up, what is most significant is the expansion of our cryogenic expertise. The knowledge we can share and provide to our customers is invaluable. The future looks very exciting.

What exactly is MeasureLINK and how does it aid material characterization experiments?

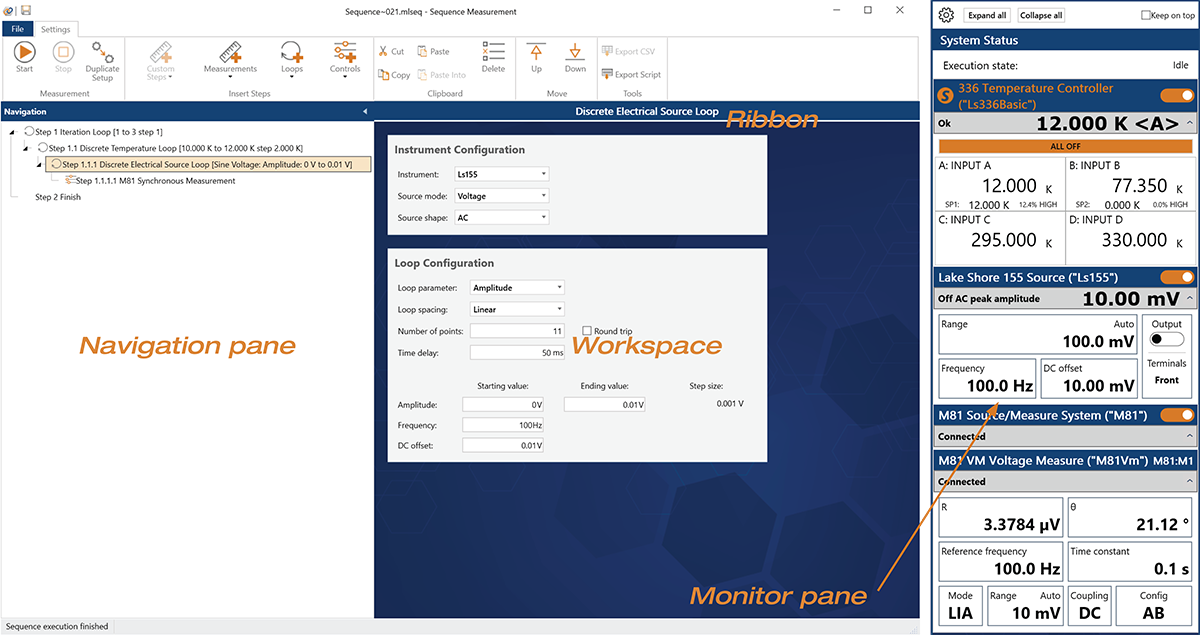

The software is now common to all new material characterization products we introduce and provides complete coordination over the experiment. With no programming required – it uses drag-and-drop control – you can construct an experiment by selecting a sequence of pre-written functional steps to control the environment and collect data, automatically stepping through your defined sequences. Users can construct multi-level parameter sweeps over the temperature, magnetic field, and rotation angles of the sample while also coordinating electrical measurements at each parameter sweep.

It also enables data collection visualization in real-time. A user, for example, can create a specific multi-variable chart for any data-collection sequence and then pin the chart to watch the data populate. MeasureLINK includes a chart recorder utility. This utility enables you to monitor certain variables, such as temperature trends, in real-time to keep a close eye on your experiment. This is a massive benefit. MeasureLINK helps confirm that an experiment is progressing as you intended so time is not wasted.

When one of our cryostats and a temperature controller are part of the material characterization experiment setup, you can use MeasureLINK to create electrical transport measurements and monitor system temperatures. A process view window in the software offers a view of cryostat internals to create a better understanding of internal temperature variations. There is also a monitor pane, which gives you an easy way to change temperature control setpoints and see settings for the various Lake Shore instruments and components used in your material characterization setup, all while using the same GUI window. The software uses industry-standard protocols and can be easily integrated with some third-party equipment.

The MeasureLINK interface includes a monitor pane which can be used to view various settings. Displayed here are temperature readings for sensor inputs on the Lake Shore Model 336 temperature controller as well as measurements settings for the Lake Shore Model 155 AC/DC current and voltage source and the modules of the M81-SSM synchronous source measure system. Image Credit: Lake Shore Cryotronics Inc.

Can you describe how the software would be used in a setup where users need to carry out Hall effect measurements of a material sample?

The software is included with Lake Shore's M91 FastHall measurement controller, which is an all‑in-one Hall analysis instrument. It automates the entire Hall measurement sequence, collecting all the data so you can easily complete a Hall analysis of a material sample without all the parameter tweaking – though that, of course, is still an option.

The FastHall controller can take a DC Hall measurement without field reversal, so this really speeds up measurement times. MeasureLINK is the interface for a FastHall controller. It is the piece that allows you to configure, initiate, and display the Hall results, and it allows you to customize measurement and test sequences to collect Hall data as a function of field or temperature.

We also offer application packs that provide the framework for running full or partial Hall measurement regimes, using the M91 as the measurement engine, and for running the FastHall algorithms both for the measurements and Hall and related parameter calculations.

The M91 FastHall measurement controller. Image Credit: Lake Shore Cryotronics Inc.

The M91 controller can be set up and queried using SCPI commands by user-written software in many languages. We also provide LabVIEW™ and Python drivers, but for most users, MeasureLINK is by far the easiest and best approach for performing measurements in typical Hall applications. This includes M91 Hall measurements carried out in a Quantum Design PPMS®. Partnering with the company, we have developed a MultiVu™ app pack for MeasureLINK, and once the M91 is connected to the PPMS electronics and the PPMS sample puck, you can then use MeasureLINK to trigger ramps to temperature or field on the PPMS system, all from a single interface.

For those who do not need material characterization instrumentation, how has the Janis product line changed since Lake Shore acquired Janis Research?

All our cryostats now ship with a Lake Shore Model 335 or 336 instrument for temperature control. The controllers include a calibrated silicon diode temperature sensor as standard. Including this type of sensor ensures more precision and less uncertainty when controlling the cryostat temperature. With respect to MeasureLINK, we can provide the software for monitoring and recording temperature changes. We think all sorts of users will like MeasureLINK by itself, even if they do not require any material characterization instruments.

What is the future for the development of MeasureLINK in respect to where early-stage material research and low-temperature experimental physics is heading?

Lake Shore releases an update with new features largely based on customer feedback each quarter. We will be adding more scripts and application packs so the base MeasureLINK software can be easily deployed in new measurement applications, such as for superconducting transition studies and differential conductance measurements of materials in addition to various electrical transport measurements. These application packs include the drivers needed to communicate with the instruments, scripts to run all the measurements, and additional utilities for reporting measurement results. We will continue to optimize the software for controlling experiments containing various components in low-temperature research applications and integrating third-party equipment.

About Nadia Dugan

Nadia Dugan, a Product Marketer for Lake Shore Cryotronics, has a MSci degree (2015) in Electrical and Computing Engineering from The Ohio State University. Her background includes developing precision instrumentation and sensors for exploring the electronic and magnetic properties of next-generation materials. She started at Lake Shore as an engineer, responsible for the design, development, and build of a new station for calibrating new and legacy instrumentation. She then moved into a Project Leader position, developing the company’s line of M91 FastHall instruments for Hall effect analysis of materials, from prototype to pilot and market launch. In this capacity, she directed cross-functional teams from proof-of-concept to production, driving collaboration and communication between software, hardware, purchasing, sales, and manufacturing teams.

This information has been sourced, reviewed and adapted from materials provided by Lake Shore Cryotronics Inc.

For more information on this source, please visit Lake Shore Cryotronics Inc.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.