Conversion coatings are coating layers applied to the surface of a metal substrate to enhance its appearance and improve physical and chemical properties, such as corrosion resistance and paint adhesion. These coatings are formed through chemical or electrochemical processes, with common examples including chromate, anodization, and phosphate conversion coatings.

Zinc phosphate and associated compound conversion coatings have been the leading choice for pre-treating steel and galvanized steel car bodies and automotive components. However, over the past decade, zirconium (Zr) and titanium (Ti) based coatings have become increasingly popular as alternatives to phosphate-based coatings.1,2 These Zr and Zr/Ti coatings offer several benefits compared to traditional zinc and zinc-manganese-nickel-phosphate coatings.1,2

Zr- and Ti-based conversion coatings improve paint adhesion and enhance corrosion protection of automotive bodies made of aluminum. Image Credit: Thermo Fisher Scientific – Handheld Elemental & Radiation Detection

The Thermo ScientificTM NitonTM XL5 Plus Handheld XRF Analyzer. Image Credit: Thermo Fisher Scientific – Handheld Elemental & Radiation Detection

- Enhanced corrosion resistance (improved salt spray resistance)

- Improved maintenance (less sludge, less scale, low foaming)

- Lower operating cost (lower temperature, less waste, and chemical consumption)

- Thinner coatings

- Reduced environmental impact and wastewater treatment (phosphate-free, no regulated heavy metals)

Thermo Scientific™ Niton™ handheld XRF analyzers are used worldwide by producers of coating chemicals, as well as factories in automotive and other industries. Niton analyzers assist in supporting the quality control of Zr—and Ti-based coatings on substrates, including aluminum alloys, cold-rolled steel (CRS), electro-galvanized steel (EG), and hot-dip galvanized steel (HDG).

The Thermo Scientific™ Niton™ XL5 Plus is the leading handheld XRF analyzer for such applications due to its unparalleled power; its fundamental parameter algorithm can simplify and improve flexibility in the workflow for application development and analysis.

Niton XL5 Plus Analyzer

Among the many high-performance X-ray fluorescence (XRF) metal analyzers available on the market, the Niton XL5 Plus analyzer is the most compact and lightweight. The compact measurement geometry, large-area detector with a graphene window, and powerful 5W X-ray tube offer exceptional sensitivity, making it ideal for even the most demanding applications, such as measuring thin coating layers.

The Niton XL5 analyzer's fundamental parameter-based, standardless Coatings Mode accurately measures the thickness of up to four layers of pure element or alloy coatings on various substrates, including pure elements, alloys, plastics, and wood.3 The Niton XL5 Plus analyzer can, therefore, easily measure the coat weight of Ti- and Zr-based conversion coatings on alloys like steel or aluminum, as well as coated materials such as galvanized steel.

It is ready to use "out of the box," requiring no extensive calibration samples or advanced training. However, for users who prefer to fine-tune their analyzer, an easy-to-use type standardization feature is available for customization with their own reference materials.

Test Method and Results

The Niton XL5 Plus analyzer was used to analyze multiple previously characterized samples of Zr- and Ti-based conversion coatings over HDG, CRS, and aluminum alloys. Only key parameters, such as the substrate type (e.g., steel or aluminum grades), coating elements (like Zinc (Zn) for galvanized steel, Zr, or Ti), the unit of measurement, and measurement time, were entered into the measurement profiles (analytical methods).

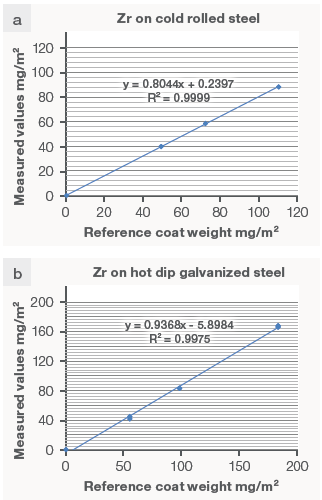

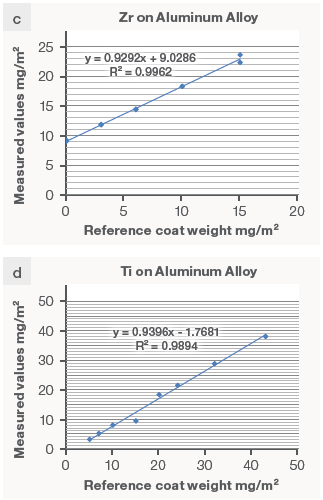

Correlation plots were generated between laboratory-obtained reference values, and measurements were conducted using the Niton XL5 Plus analyzer for Zr and Ti on various substrates. Zr and Ti are typically present in coatings at levels equivalent to just a few atomic layers. The correlation coefficient (R2), along with the slope and intercept of the linear regression, is provided in Figures 1a-d.

The R2 value reflects the correlation strength between data sets, with an R2 of 1 indicating perfect correlation. Assuming a strong correlation, the slope serves as an indicator of the analyzer's accuracy, with an ideal slope being close to 1. High intercept values in the calibration curve may indicate the presence of the coating element within the substrate itself.

With an R2 value exceeding 0.98, the measurements obtained using the Niton XL5 analyzer with Coatings Mode "out of the box" demonstrated a strong correlation with laboratory reference values for Zr and Ti across different substrates. The slopes were close to 1, around 0.93 for Zr on HDG (Figure 1b) and for Zr and Ti on aluminum (Figures 1c and 1d). A slope of 0.804 was observed for Zr on CRS (Figure 1a), deviating from the ideal slope of 1.

Figure 1. Correlation curves measured versus reference values obtained without any calibration adjustment for a) Zr over cold rolled steel, b) Zr over hot dip galvanized steel, c) Zr over aluminum (coating # 1), d) Ti over electro-galvanized steel, Ti over aluminum. Image Credit: Thermo Fisher Scientific – Handheld Elemental & Radiation Detection

This deviation is likely due to the presence of other compounds and elements in the coatings, which affect the density and mass absorption coefficient of the matrix and, thus, the Zr signal. In such cases, a simple post-calibration adjustment using the type standardization feature can enhance the accuracy of the measurement for specific formulations.

In the case of Zr over aluminum, an intercept value of 9.03 mg/m2 in the linear regression deviated significantly from zero, indicating the presence of Zr in the substrate itself.

Zr, along with Ti, is often present in aluminum alloys at trace levels not explicitly specified by alloy grade standards. To address this, it is recommended to measure both a coated and non-coated sample from the same batch and calculate the difference.

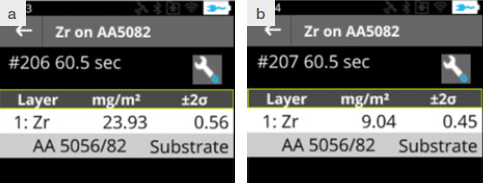

For example, as shown in Figure 2a, the measured coat weight for a Zr-coated aluminum sample was 23.9 mg/m2, compared to the expected 15 mg/m2. The non-coated substrate from the same batch yielded 9.0 mg/m2 of Zr (Figure 2b). Subtracting this value from the coated sample’s result gives a net Zr value of 14.9 mg/m2, which closely matches the expected 15 mg/m2. This subtraction method is only applicable when the coating layer is thin, as is the case with Ti- and Zr-based conversion coatings.

Figure 2. a) Analytical results for an aluminum alloy grade AA5082 sample coated with 15 mg/m2 Zr, b) Non-coated sample of the same batch of alloy AA5082. Image Credit: Thermo Fisher Scientific – Handheld Elemental & Radiation Detection

Conclusion

The Niton XL5 Plus analyzer is well-suited for contemporary conversion coating applications. Good correlations and agreements were acquired between expected and measured values of Zr and Ti over a range of substrates, including steel, galvanized steel, or aluminum alloys.

Compared to the empirical calibrations available on the Niton XL3 analyzer, the fundamental parameter-based Coatings Mode of the Niton XL5 Plus analyzer is easier to use, more flexible, and requires fewer reference samples. The accuracy of the standardless calibration can be assessed with just a few samples per coating type. If necessary, the user can easily fine-tune the analyzer’s response to achieve optimal accuracy.

The Niton XL5 Plus analyzer has proven ideal for controlling the coat weight of Zr- and Ti-based coatings in the automotive and metal finishing industries. Its fast return on investment is driven by several key factors:

- Increased productivity — The Niton XL5 Plus provides real-time coat weight measurements within seconds, allowing for immediate control of the coating process and rapid decision-making in quality control for finished or semi-finished products.

- Ease of use — The Niton XL5 Plus requires no specialized lab personnel for method development or operation.

- Non-destructive analysis — The analyzer can be used directly on finished products without cutting samples or transporting them to a lab.

- Lab-quality analytical performance: The analyzer offers performance comparable to laboratory instruments but with lower initial investment and operational costs.

- Versatility — The Niton XL5 Plus analyzer can be used to determine the alloy grade versus specification of non-coated materials, including aluminum alloys.

References and Further Reading

- Gardobond® X 4707 Product Info, www.chemetall.com, Chemetall GmbH, Frankfurt am Main, Germany 2012.

- I. Milosev, G. S. Frankel, Review—Conversion Coatings Based on Zirconium and/or Titanium, Journal of The Electrochemical Society, 165 (3) C127-C144 (2018).

- M. Bauer, Application Note: Measuring Metal Coating Thickness at Line using the Thermo Scientific Niton XL5 Plus, Thermo Fisher Scientific, Tewksbury, MA, USA.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Handheld Elemental & Radiation Detection.

For more information on this source, please visit Thermo Fisher Scientific – Handheld Elemental & Radiation Detection.