Image Credit: Stable Micro Systems Ltd

A Standard Test Method is a conclusive procedure that yields a test result. So as to achieve accurate and relevant test results, a standard test method is definite, unambiguous, and experimentally viable, as well as being reproducibly effective.

A standard test method can be regarded as an experiment that establishes one or more characteristics of a given sample and the detail of the test method is typically a result of creation from several experts in that measurement field.

For example, within the materials testing industry there are a vast number of standard-methods (e.g., ASTM, ISO) that have been developed specifically to measure sample characteristics.

Standard examples of those that use Texture Analyzers or Materials Testing equipment are:

- ASTM D882-02: Tensile test of thin plastic sheeting (thickness<1mm)

- EN 1944:1996 - Self Adhesive Tapes - Measurement of Unwind Adhesion at Low Speed

With detailed results in an industrial report or academic paper, these standard-methods will have been followed closely for the collection of the results. The reason that standard methods have their place in the laboratory is that they are understood globally by others using the same standard test methods.

A great number of companies utilize one of a suite of Texture Analyzers to determine fundamental parameters that account for the dimensions and geometry of the sample as well as test set-up specifics along with the relevant engineering equations.

This type of testing enables the simple comparison of different samples and contrast with literature data. Yet, it does necessitate an increasingly sophisticated analysis to convert forces to stress and distances to strain.

Materials parameters can be performed on a range of instruments of different load capacity. Image Credit: Stable Micro Systems Ltd

Texture Analyzers are frequently used for quality control of unconventional products by the use of empirical measurements. The force necessary to crush a tablet or measure the distance a biscuit bends before it breaks are crucial pieces of information that manufacturers look for when developing new products, or ensuring products perform appropriately during spot checks.

This type of test is perfect for products that have an atypical geometry, but it is also useful for testing more complex systems, such as the combination of a product and its packaging: e.g. a box of eggs, a yogurt in its pot, or the force to open a ring pull can.

There is also an advantage of the time saved by enabling the testing of a product straight off the supply line. Here classic examples of where empirical testing has a place are evident, as measurements of this nature do not fall within the specific and therefore restricted dimension criteria of fundamental materials.

For example, in the food industry, there are fewer standard methods for physical property measurement. Yet, one of few specific standard-methods may already be in place for the testing of samples, e.g. ISO Gelatine Bloom Strength, AACC Pasta Firmness, AACC Bread Freshness, ASTM Adhesive Peel Strength, ASTM Petroleum Wax Firmness.

The restrictions that occur when applying certain standards is that their main benefit of being specific can be a considerable disadvantage to the measurement. It is common for operators to use standard-method to measure a property of a product when:

- The property that the standard-method measures is not the most crucial, or interesting, a measurement that could be performed on the sample

- The sample preparation procedure may be complicated, or even impossible to conform with when the sample to be tested differs from the sample for which the test method was developed.

A thorough and well-documented test method is crucial. Even more critical is selecting an appropriate method of measuring the correct characteristic or property. Not all tests and measurements are always uniformly useful: typically a test result is utilized to predict or infer suitability for a specific purpose.

Yet, it would seem more viable to measure the key characteristics of a product rather than follow an arbitrary standard-method that does not optimally characterize the product.

If there are no pre-existing constraints and the most-simple testing solution is required, sometimes the best approach is to create a test that imitates the way the product is assessed in real life. This is known as an ‘Imitative Test’ and tends to make the interpretation and understanding of the data much easier.

For certain industries, an agreement regarding the method of measuring the physical characteristics of products is almost impossible. Whilst some processes can be agreed upon internationally, they are not always accepted universally. Standardization of methods is crucial if investigations conducted by various groups are to be comparable to one another.

The methodologies used for physical testing should measure characteristics deemed desirable and necessary to the monitoring process, but they do not always need to be comparable with other laboratories, where different criteria may be key.

Where the emphasis is placed on the international comparison is crucial to standardize the methodologies. This includes all aspects of the testing procedure and this is an area of primary directed for the reference methods.

By way of comparison, where the direct measurements of physical properties of a product are taken, the experimental methodologies should not be restricted by reference methods.

Rather, researchers should be motivated to design and use methodologies that improve the precision and accuracy of testing methods and develop an understanding of the basic mechanisms.

It is likely that new methods will emerge from a greater understanding of measurements that accurately predict consumer assessment of product characteristics.

The Stable Micro Systems range of Texture Analyzers offers the flexibility of testing principles (e.g. compression, penetration, tension, extrusion, etc.) and a limitless option of probes, fixtures, and data analysis techniques within the software for texture analysis and test settings that can be completely customized.

Whilst standard-methods are indeed useful for conventional material forms that have not been modified over the years or those that are fully accepted, there lies another world where ingenuity has expanded into new materials and material forms for which these standard-methods cannot be applied.

For example, in the field of pharmaceutical development where traditional methods are well-established for the testing of tablets, suppositories, gels, and medicated liquids that are manufactured in their traditional form.

Yet, state-of-the-art dosage forms have been designed including disintegrating films, capsules, chewable pastilles for which no standard-method can be applied for the measurement of their physical (or textural) characteristics.

Non-standard testing methods are required in order to facilitate the testing of samples of different types, dimensions, and the range of additional material characteristics that can be measured.

Non-standard methods are not only valid where sample dimensions cannot be prepared in-line with the standard but also where the operator may desire modification of the test parameters, such as the test speed, to closely replicate the situation under which the sample is to be frequently used.

Note, it is always vitally important to recognize that the exchange of a test parameter or sample preparation technique should be detailed for the purpose of any subsequent comparison.

Data Analysis and Engineering Calculations

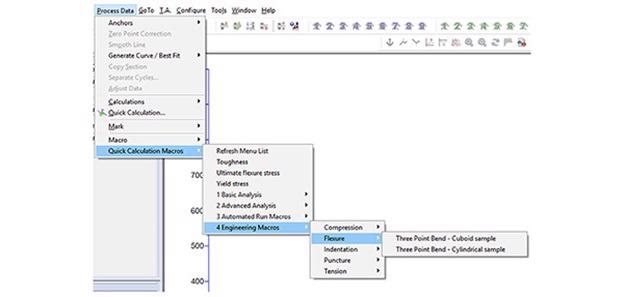

If fundamental testing is critical to operation and preferences are unaltered for this means of testing then standard engineering calculations are integrated into Exponent software for rapid calculation of particular energies, moduli, stresses, strains and strengths which are specifically suited to materials testing applications.

Each calculation is developed to be utilized with a very specific test setup (for example, cuboid three-point bend testing) as the specified equations required for analysis rely on the sample and test geometry.

Image Credit: Stable Micro Systems Ltd

Types of Test and Their Analysis Possibilities

Regardless of whether the test is performed in compression or tension, analysis of a resulting curve can be performed to obtain the following typical parameters:

- Breaking strain

- Energy to failure

- Energy to maximum stress

- Hysteresis %

- Maximum stress

- Resilience

- Strain rate

- Strain at maximum stress

- Strain to yield

- Tangent, chord and secant modulus

- Young’s Modulus

- Yield stress

- x% proof stress

When specifically measuring in tension additional parameters may include:

- Necking onset

- Strain hardening parameter

- Strength coefficient

- Ultimate tensile strength

Flexure using three-point bend for cuboid and cylindrical samples:

- Flexural strength

- Toughness

- Yield stress

- Young’s Modulus

Indentation utilizing conical and spherical probes:

- Elastic energy

- Hardness

- Indentation energy

- Indentation modulus

- Plastic energy

Puncture of uniform thickness thin films with spherical probes:

- Failure Strain

- Stiffness

- Strength

- Toughness

Whilst the equipment can offer a straightforward, flexible empirical or imitative solution it also facilitates the well-established, conventional measurements within the materials industry.

Over the years, Stable Micro Systems has introduced a vast number of test procedures and analysis methods appropriate for the acquisition of fundamental materials parameters that could be utilized across a wide range of industries.

For a summary of typical texture analysis tests that can be conducted on materials, watch this video to see the highlights: https://www.youtube.com/watch?v=D1cNQP--CZw

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.