Image Credit: Stable Micro Systems Ltd

Today, manufacturers are aware of the role and significance packaging plays in the success of their businesses. This is particularly evident in the fast-paced consumer goods (FMCG) arena.

No matter how valuable or desirable a product is, poor packaging may result in failure thereby making the product unfit for purpose, impossible to handle and store, or even unsellable. The poor performance of the packaging can not only damage a product, but it can harm the reputation and profitability of the company that supplied it.

Consequently, materials testing for packaging materials and finished packs is now as crucial as the product evaluations themselves.

Manufacturers can establish which packaging types best meet their individual needs due to the availability of a wide range of testing equipment and methods; from evaluation of substrates and adhesives to the filled packs that are ready for shipping and sale.

The tests detailed below can be conducted using various rigs and attachments in combination with either the TA.XTplus Texture Analyzer or TA.HDplus Texture Analyzer.

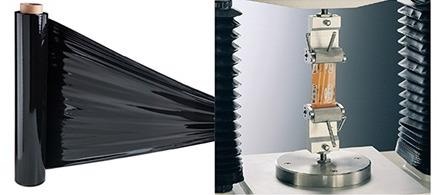

Using grips, it is possible to measure the tensile strength and tear characteristics of packaging. Self-Tightening Roller Grips are best for thin samples with a smooth surface, or materials whose characteristics adjust upon the application of tensile force.

Spring-loaded crosshatched rollers work as self-tightening mechanisms that grasp the sample at each end, applying the pull force to establish the rupture point. On the other hand, Tensile Grips are perfect for testing the mechanical properties of heavy-duty packaging materials such as heavier plastics.

With a simple pulling action, the instrument measures the maximum force needed to stretch the sample to its breaking point. By way of contrast, when used in a cycling motion, tensile grips gauge the flexibility of the substrate material.

Comparative evaluation of different materials enables the manufacturers to choose the right packaging materials that are strong enough to stand up to the rigors of handling and distribution but simultaneously enable users easy access to the product inside.

Image Credit: Stable Micro Systems Ltd

Image Credit: Stable Micro Systems Ltd

As well as strength, friction can have a considerable impact on a packages’ performance characteristics, especially during the shipping and handling processes. The coefficient of friction (COF) is representative of the resistance of two surfaces sliding when in contact with each other - higher COF values infer an increased resistance.

Too much friction can lead to material damage or deformation, but insufficient friction can result in slipping which can be an issue during product storage and/or display.

The Coefficient of Sliding Friction Rig allows manufacturers to establish static and dynamic coefficients of friction by affixing the reference material to the rig’s base and the test material to the sled.

The sled is then pulled across the reference material at a sustained rate, while the instrument measures the force. ASTM D 1894-90 is the recognized standard for plastic sheeting and films.

Image Credit: Stable Micro Systems Ltd

Amongst the most popular methods of packaging are peel lids and covers for applications such as medical devices and FMCG products; specifically in personal care and sections of the food industry. In addition to measuring the characteristics of the material of a lid when it is in the form of a sheet, it is of equal importance to examine adhesion to the pack.

How the seal bond performs between lid and pack is not only crucial to the safety and quality of the products in the container but is also a key factor in user-friendliness. The adhesive bonds must be both robust enough to withstand shipping, handling and storage without puncture or tear, while being simple to peel back when required.

Image Credit: Stable Micro Systems Ltd

A common test entails the use of the Peel Strength Test Rig. The container is placed in a carrier plate mounted on the base of the instrument. This carrier plate is then arranged so that a pulley and captive wire are located exactly beneath the loadcell of the instrument. One end of the wire is attached to the loadcell and the other is connected to the pull-tab on the lid.

Image Credit: Stable Micro Systems Ltd

The Universal Peel Rig is comprised of a multi-position platform, enabling containers to be held flat, or at 45° and 90° angles. With this method, manufacturers are able to simulate the action of consumers more accurately in order to evaluate both the stability of packaging seals and ease of use.

Image Credit: Stable Micro Systems Ltd

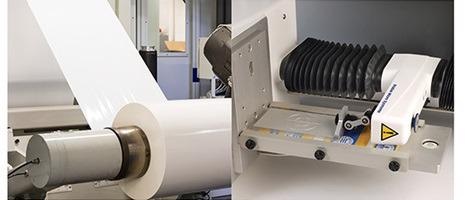

Sachets and tubes have become progressively popular as the quality of plastic has been steadily improved as manufacturers seek lighter and more flexible packaging formats.

In sectors as wide-ranging as personal care, food, healthcare, hardware and hobbies and crafts, handling transport and storage are improved upon while making sure users can easily access the contents.

During the application, if the assumption is made that the aperture of the tube/sachet is fixed and the product’s consistency/flow properties are appropriate, the consumer’s ability to squeeze the packaging is the key to success.

A Sachet/Tube Extrusion Rig vertically secures the product between two rollers, with a grip clamping the closed end at the top. Following this, the grip pulls the sachet/tube through the rollers in an upwards motion, forcing the contents out.

If the force recorded during this test is high, a consumer would experience great difficulty in squeezing the contents out. In the food industry, if the product’s consistency changes throughout its shelf-life the results may vary over time.

Image Credit: Stable Micro Systems Ltd

The principal requirement in most blister pack applications is safety as they are popular for use in healthcare and medicine. This can be a difficult balance to maintain.

Blister packs must be childproof, but also ready for use quickly and easily by consumers that may not have full strength in their hands and fingers, such as elderly people. A Blister Pack Rig emulates a users’ actions utilizing a vertical probe that simulates a human finger descending downwards onto the sample pack, applying a steady amount of pressure on to the blister pocket.

Image Credit: Stable Micro Systems Ltd

The instrument measures the force necessary for the sealed surface of packet to be ruptured by the probe.

Uniaxial compression testing allows manufacturers and retailers to assess the crush resistance of packaging containers, appraising their resistance to deformation when even force is applied across a surface. This is vital if the contents of a pack are fragile and/or valuable.

Image Credit: Stable Micro Systems Ltd

The test uses a Compression Plate that moves downwards in a vertical motion with a constant speed while applying a set pressure onto the sample placed directly below. The force necessary to deform the sample container is recorded, providing an insight into how well the pack will withstand storage, transport and handling.

Uniaxial compression tests of small boxes are frequently conducted throughout the pharmaceutical, food and beverage, cosmetic and FMCG industries.

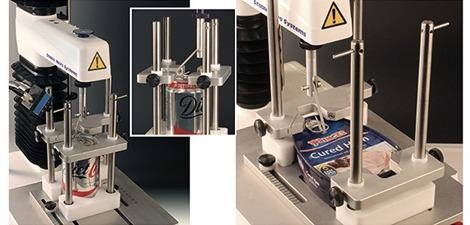

Testing carbonated drink can ring pull force and Testing tinned ham ring pull force. Image Credit: Stable Micro Systems Ltd

Understanding and quantifying the force required to use a ring pull is crucial for both manufacturers and their customers to guarantee safety, functionality and good consumer experience. The force necessary to open tins and cans is determined by the shape of the ring pull and lid as well as the materials and the depth of the groove in the lid.

Previously, only subjective methods were accessible for evaluating ‘force to pull’, which until recently made it difficult to establish the best design that offered both packaging integrity and ease of use.

The Ring Pull Rig enables the manufacturers of food tins and beverage cans to observe the force required to lift the ring pull and open the container. The use of this rig on the latest products could be the indicator of the end of consumer frustration when attempting to open metal packaging that is too rigid, or where the ring pull detaches from the lid.

The rig operates by fixing the product in place on the TA.XTplus Texture Analyzer and connecting a hook adapter to the ring pull. The hook is drawn upwards, replicating the action of a person opening the can, while recording the force necessary to lift the ring pull and ultimately break the seal.

Due to the design of the Ring Pull Rig being universal non-circular shapes, such as meat or fish cans, can also be analyzed with good accuracy. The Exponent software’s flexibility has facilitated the development of a special test for tins that necessitate a two-step pulling action.

The rig initially measures the force required to break the seal before pausing which simulates the user to adjusting the hook direction or rotating the tin. The second part of the test then records the force necessary to completely peel and remove the metal lid.

Packaging designers and engineers can establish the right balance between safety and convenience for the consumer by understanding the force needed to open cans and tins. The Ring Pull Rig has the ability to give manufacturers an acute analysis of opening behaviors so they can enhance the development of future products.

When the device is utilized with a Video Capture and Synchronization System, the user has the ability to replay the test data frame-by-frame for a more forceful in-depth analysis.

Using of an Acoustic Envelope Detector enhances the rig in order to capture and measure the ‘fizz’ sound of a carbonated drink.

It is clear that precise, repeatable materials testing is as crucial to the evaluation of packaging as it is in improving the product itself. Manufacturers and brand owners can protect quality standards and ensure consistent performance throughout production processes, transport, storage and end use by utilizing just one instrument.

Improving packaging enhances functionality, product safety, aesthetics and customer satisfaction. In today’s fast-paced markets, each and every aspect of these factors count.

For a full summary of typical texture analysis tests that can be performed on materials such as packaging: https://www.youtube.com/watch?v=D1cNQP--CZw&t=45s

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.