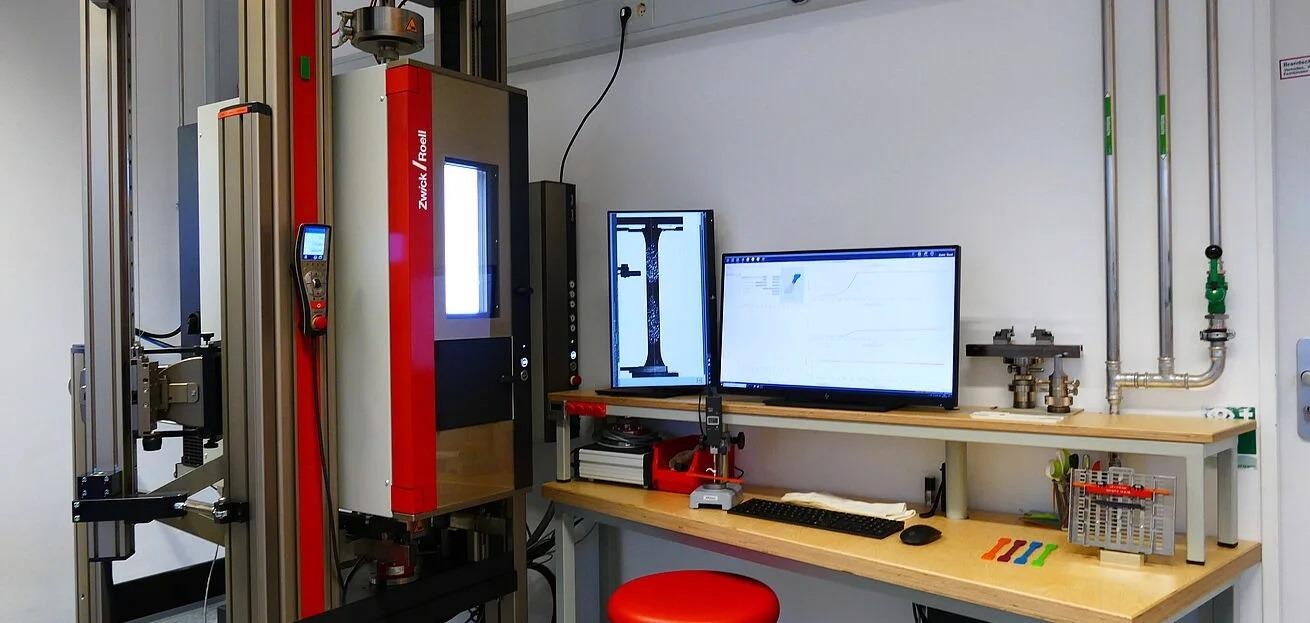

Image Credit: ZwickRoell GmbH Co. KG

For over 12 years, the expertise of Polymerphys IK has been trusted in the field of polymers by processors, raw material manufacturers and users. To facilitate further expansion of their testing services, the company selected a testing machine equipped with a temperature chamber from ZwickRoell.

Polymerphys IK is the principal testing laboratory for polymers in the Rhine-Main metropolitan region, identifying physical material characteristics in line with global test standards or in accordance with customer requests; always championing the company motto, “You bring it, we’ll break it. That’s a promise!”

To expand its test portfolio, the company acquired a new AllroundLine (Fmax 30 kN) testing machine.

The testing system’s main components are comprised of a temperature chamber (- 80 to 250°C) with door-in-door principle, magazine to precondition specimens and temperature sensor in close proximity to the specimen, as well as a flexure test kit, BoW specimen grips and a video extensometer type 2-120 HP.

After a test phase that spanned the course of several weeks, Managing Director Knut Laumen confirms the new machine’s superior position in the market:

- Stable temperature control: Polymerphys IK has extended its test reports with the test temperature over test time graph because the control works so well.

- Small, easy access door to swap-over the specimens: the temperature inside only varies by a few tenths of a degree Celsius when swapping the specimen. The curtain mounted behind the door is extremely effective in limiting temperature fluctuations.

- Noise level: the exceptionally low noise level of the temperature chamber facilitates a good work environment with acceptable noise levels.

- The body over wedge specimen grips rapidly and quietly close, making sure not to cause extra travel through gripping, which would be interpreted incorrectly as nominal strain.

- Extensometer: the videoXtens offers uncomplicated measurement of the deformations in tensile and flexure tests.

- Fan rotation speed is easily controlled.

- Load cell: the Xforce K+ 10 kN load cell has shown optimal performance for the tensile and flexure tests in the testing field due to the fact a change to smaller load cells is not necessary.

- High strains: the testing machine’s predecessor with temperature chamber achieved maximum elongation on a typical specimen of 230%. The latest testing machine, based on a typical specimen, achieves maximum elongation of 410%, which greatly impresses the customers of polymerphys IK.

This information has been sourced, reviewed and adapted from materials provided by ZwickRoell GmbH Co. KG.

For more information on this source, please visit ZwickRoell GmbH Co. KG