The global pandemic has drastically changed working practices, with many researchers now undertaking ambitious analyses from home and pushing back the frontiers of science from their kitchen table.

Long before lockdowns and the move to working from home, automation of Kratos X-ray photoelectron spectrometers was developed with the goal of increasing sample analysis throughput. This feature has naturally become a significant asset over the past year.

This article explores the value of automated sample handling, as well as a number of other aspects of automation that can be used to conduct sample surface analysis remotely.

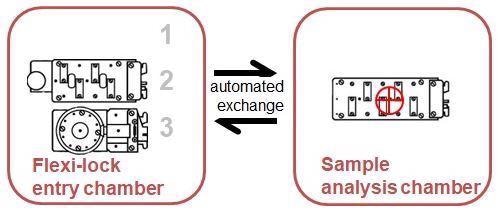

It should be noted that automated sample introduction and automated sample exchange are different features. This difference is clearly highlighted in the way users interact with the spectrometer. Kratos AXIS instruments automatically exchange the sample holder after analysis has been completed. This means that analysis can continue 24/7, and the instrument does not sit idle if analysis ends outside of normal working hours, for example.

Automated exchange of sample holders means that Applications Specialists are only required to visit the laboratory once or twice a week in order to mount samples.

Image Credit: Kratos Analytical, Ltd.

The instrument is able to accommodate up to three sample holders, meaning that analysis can continue uninterrupted for up to three times longer than an instrument utilizing conventional one-in-one-out automated sample introduction.

The use of automated sample exchange allows out-gassing samples to be stored in the load-lock as analysis proceeds in the analytical chamber. This feature effectively eliminates the time-consuming bottleneck commonly experienced while waiting for samples to pump down.

AXIS Supra : automated sample exchange

Video Credit: Kratos Analytical, Ltd.

Fully realizing automation’s potential for remote data acquisition means moving beyond sample handling and also automating XPS analysis. Automated data-dependent acquisition methods can be employed to ensure that the best possible data is acquired easily and without interruption.

Feedback loops are used to ensure that the instrument is always fully optimized. Analyzing samples and generating reports from home can therefore be performed as simply as it would be if the user were interacting with the spectrometer directly.

Automating the gas handling process has been an essential innovation in terms of remote instrument operation. This has been especially clear for the latest generation of multi-mode gas cluster ion sources.

Gas pressure regimes in conventional monatomic Ar+ or Arn+ gas cluster modes differ considerably. Low pressure Ar gas is introduced directly into the electron ion source’s impact ionization region when working in monatomic Ar+ mode. In gas cluster mode, however, a nozzle is used to introduce high pressure Ar gas, creating the Ar clusters via adiabatic expansion of the gas.

Automated gas handling guarantees that the correct sequences are followed, ensuring that the ion source is operated correctly. It also allows unattended changing between monatomic and cluster modes as part of an experimental workflow.

AXIS Supra+ and AXIS Nova, automated X-ray photoelectron spectrometers. Image Credit: Kratos Analytical, Ltd.

Automation can also be extended to accessories, for example, ultraviolet photoemission spectroscopy.

The UV-photon source needs a strictly controlled supply of He gas in order to create the UV radiation, and the use of software to control gas supply means that switching between X-ray and ultraviolet photoelectron spectroscopy can be achieved without operator intervention.

This approach also means that complex analyses such as depth profiles and UPS are made simpler for the user, even when working remotely.

When considering the many advantages of contemporary spectrometers, the words of Bill Gates should be reflected upon: ‘Automation applied to an inefficient operation will magnify the inefficiency.’

This leads to the conclusion that automation is highly beneficial, but the operator remains the most essential component in terms of generating valuable data. Automation has the potential to make using the spectrometer simpler for the experienced analyst and less intimidating for the novice user.

Robust experimental design and a thorough understanding of what information XPS and related surface analysis techniques are able to offer is key, and is as essential as instrument automation in supporting successful remote analysis.

This information has been sourced, reviewed and adapted from materials provided by Kratos Analytical, Ltd..

For more information on this source, please visit Kratos Analytical, Ltd..