Apr 20 2021

What is Particle Measuring?

The process of sizing and counting particulates in a sample is called particle measuring and can be performed in either liquid or air. Industrial processes such as semiconductor wafer fabrication use this technique prominently.

These processes have a requirement of high fluidic purity and are especially concerned with the presence of particulate contaminants as they can lead to system damage or product waste.

The Challenge

Particle measurement is used in semiconductor wafer fabrication processes to ensure that cleaning, cooling, and chemical fluids are contaminant-free. The space required and size of the equipment needing for performing this analysis has started to become an issue for industries like these as they begin to leverage the power of particle measuring against contamination.

System integrators and OEMs require easy integration without needing expensive platform redesigns. Specialist instruments used for a liquid particle can be integrated into the production line. A balance of low noise and high power in a high reliability, compact platform is delivered by equipping such instruments with high power lasers.

How Does Particle Measuring Work?

A range of materials and sizes can have particulates present. It is therefore critical to determine the properties of the contaminant in order to understand its presence and the possible source of contamination.

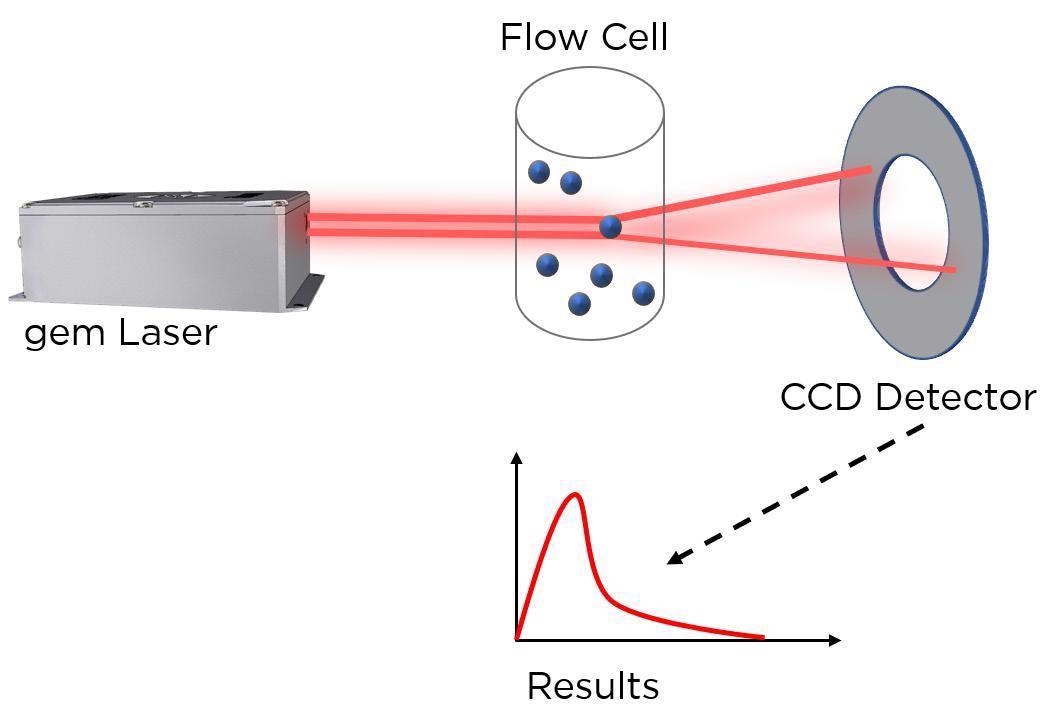

Air-cooled laser solutions are employed to accurately determine the properties of the contaminant. The laser is used in conjunction with either a CCD camera or an array detector to analyze the diffracted light. This is used to determine the properties of the particles that pass between them.

A 532 nm gem or opus laser from Laser Quantum, a Novanta company, is well-suited to this application, depending on the required power. To do this, the laser beam, at an angle perpendicular to the liquid flow, is directed through a flow cell.

The beam is then precisely directed through the liquid toward a pinhole aperture with beam dump. The light gets diffracted away from the beam dump by any particles that strike the laser beam.

Schematic of how particle measuring works. Image Credit: Laser Quantum Ltd, a Novanta Company

Photograph showing a system employing particle measuring. Image Credit: Laser Quantum Ltd, a Novanta company.

There is a complex array photodiode or CCD around the beam; a reading corresponding to the size of the particle and the quantity of particles detected is generated by the diffracted light signal from the particle.

The purity of the liquid is determined by this process, and the contamination state of the process is decided by this information. Therefore, it is of critical importance that the readings have zero false positives and are highly accurate.

Otherwise, there is a risk of unnecessary downtime and waste manufacturer. The opus and gem lasers from Laser Quantum, a Novanta company, are designed to exhibit very high beam quality (M2 close to 1).

Additionally, these lasers provide systems with a high degree of reliability and consistency in the diffracted light because they maintain a highly stable beam pointing accuracy, which significantly reduces the likelihood of false positives.

The Solution

Laser Quantum, a Novanta company, has a design philosophy to deliver reliability and very high performance over the longest lifetimes, a philosophy that can be seen over the company’s long heritage in developing lasers for mission-critical industrial applications.

Laser Quantum, a Novanta company, has developed a series of lasers with the system builder in mind that are specifically meant to address the specialist requirements of this application.

The opus 532 nm and gem 532 nm lasers use patented high performance cavity technology to maintain constant low noise over long periods of time; this is one of the key characteristics within the particle measurement process to maintain very low false positives.

A key design feature across all Laser Quantum, a Novanta company, products is the ease of integration.

A high wall plug electrical efficiency and small form factor are featured in both opus and gem families, which deliver distinct benefits in thermal management, enhanced by an advanced air cooling system that enables the use of the lasers in environments where water cooling is not feasible or permitted.

A defining feature of all Laser Quantum, a Novanta company, products is advanced integrated power feedback.

This feature means that the laser is able to intelligently optimize and maintain its own power levels so that it is able to maintain beam specification without power fluctuations, making these lasers truly the correct choice for high reliability, 24/7 system integrated applications.

The gem and opus lasers from Laser Quantum, a Novanta company. Image Credit: Laser Quantum Ltd., a Novanta Company

This information has been sourced, reviewed and adapted from materials provided by Laser Quantum Ltd., a Novanta Company.

For more information on this source, please visit Laser Quantum Ltd. a Novanta Company.