A research team has recently published research about exciting advances in microactuator fabrication for soft microrobots. It has been developing its technology within Linkoping University’s Department of Physics, Chemistry, and Biology (IFM). The report was published in the Soft Robotics journal. In this article, the significance of the team’s design-to-product process improvements is considered as it expands the possibilities for manufacturing these micro-devices using extrusion 3D printing.

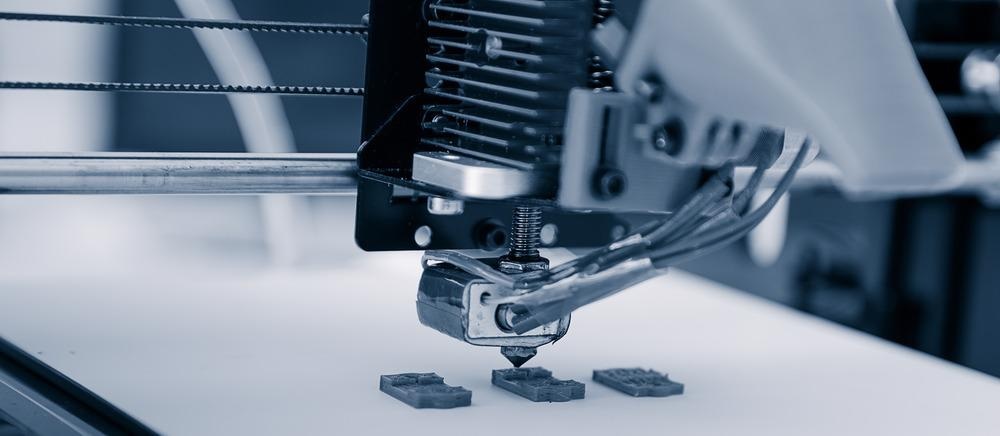

Image Credit: Alex_Traksel/Shutterstock.com

Soft Microrobots

Usually created from highly compliant, often bio-inspired materials, soft microrobots occupy a fascinating sub-field of robotics. With their flexibility and adaptability, they find deployment in an extensive range of applications where space is restricted, or there is an inherent danger for human intervention, for example, in emergencies such as bomb threats, disaster relief, or spillages of toxic material.

Equally important applications have evolved for the tiny soft robots in human interaction scenarios (creating a protective environment between machine and person) and when safely incorporated into the human body, driving the field of medicine to the next level.

Fundamental to the control of soft microrobots are physically flexible, small-scale electronics and, in particular, active devices capable of generating mechanical motion called actuators that operate under feedback control engineering where dimensional changes can be implemented electronically.

Historical Microactuator Manufacturing

Although piezoelectric materials are of limited flexibility, they were initially used to produce actuators until additive manufacturing techniques gained traction, replacing the complexity and time-consuming nature of photolithography, which, along with laser ablation, had been the preferred adopted processing technique.

Additive manufacturing typically produces three-dimensional (3D) objects under computer control from a computer-aided design (CAD) model. Objects are made by depositing, joining, or solidifying materials, typically layer by layer.

Additive manufacturing offers significant advantages over previous technologies, including easier product alteration, more straightforward designs, minimal waste, and less energy.

Initially, the materials selected to produce soft microrobot microactuators included ionic polymer–metal composites, creating numerous shapes. The use of hydrogels helped develop devices comprised of materials that could be deformation reversed or easily morphed.

Other materials investigated have included soft dielectric elastomers and shape memory polymers, but they have all had one unfortunate commonality. Despite easy manufacturing, all actuators produced by these materials have been limited to the centimeter scale with minimum thickness limited to 0.02 cm.

Scaling Down

Material thickness is critical in the context of actuators. Achieving movement with lower actuation potentials and high power-to-weight ratios requires thinner materials. For efficiency, actuation potentials lower than 4–5 kV are desirable. This is where the results of Jager et al. hold great significance as they demonstrate micrometer structures produced by 3D printing where limits have been driven down below 200 μm.

Scaling down to microrobotic devices is a challenge for the extrusion-based 3D printing technique called fused deposition modeling that used a filament of thermoplastic material the team adopted to explore dimensional limits. The method helps to lower manufacturing costs and the possibility of accelerated prototyping when electroactive polymers (EAPs) are used. With electric field stimulation, EAPs exhibit much greater size and shape changes in comparison to ceramic actuators.

Hardware and Software

In terms of hardware, the scientists used a bespoke extrusion 3D printer that incorporated a three-axis (x-y-z-axis) programmable milling stage augmented by a fluid dispensing system. A silver/silver chloride reference electrode was chosen for electropolymerization, while a counter electrode composed of titanium mesh was selected. In terms of the software, an aliphatic urethane acrylate gel (cured using UV) was dispensed using a taper tipped-syringe (5 mL), while standard glass slides coated with a 40 nm layer of gold were used as substrates for the 3D printing experimentation undertaken.

Extending Capability

Exploiting the versatility of the 3D printing process, the team has developed a new patterning process. Using just one extra printing step to transfer the design, the electrical layer is patterned using what the team has termed “lift-up” where physical removal of a printed layer initially printed over the gold-coated glass substrate is expedited.

The desired patterned gold-coated substrate is left behind as the gold is removed from the glass. This could be considered the reverse of the “lift-off” process, where patterned structures of the target material are created using a sacrificial photoresist. Therefore, potentially deleterious etchants damaging the devices being produced are avoided in this novel process, offering a step-change in methodology.

Microactuators with 3D-printed bodies of varying lengths ranging from 1000 to 5000 μm were fabricated, allowing the fabrication and subsequent operation of microrobotic devices with rigid bodies that generate individually controlled free-moving arms or legs. This enabled the group to explore the microfabrication of a range of soft grippers and manipulators via multiple microactuators.

The results highlighted the fabrication of multiple actuating armed (2-4) microrobot and dimensions ranging from 6 x 4.5 to 14 x12 mm2. Successful scaling down of actuators to dimensions of 300 x 1000 μm and a thickness of 20 μm has resulted in the team finding that only low operating potentials (0 to -1V) are required for satisfactory manipulation. For example, the smallest robot exhibited improved bending when operating between 0.005 to 1.0 Hz in terms of frequency. Achieving displacements from 100 to 3000 μm are typical.

The team’s simple ‘‘patterning by printing’’ has introduced exclusive device designs by enabling individual control of different flexible arms attached to the same microrobot body.

Driving the limits of 3D printing down into the micrometer domain has allowed the generation of sufficiently small and thin microactuators with independent actuation and independently controlled limbed devices. In doing so, the team is extending what is possible, increasingly enhancing the capability, reach, and complexity of manipulation that soft microbots can possess.

References and Further Reading

Jager, E. et. al. (2021) 3D Printing Microactuators for Soft Microrobots. Soft Robotics http://doi.org/10.1089/soro.2019.0129

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.