Differential scanning calorimetry (DSC) is a practical method for the characterization of food products, including:

- The gelatinization and staling (retrogradation) behavior of starches

- Polymorphism of fats such as cocoa butter and chocolate

- Effects of moisture content or absorbed moisture

- Aging effects

- Protein denaturation

- Determination of fat content or solid fat index (SFI)

It has been discovered that the processing and handling behavior of food fats depends upon the solid-to-liquid fat ratio in the food sample. A number of rheological or flow properties, and their consequent effect on the texture of the final product, derive from this fat ratio index.

The study of the fat content and type of fats in foods is increasingly becoming more important for health reasons, especially with regards to the content of solid fats, saturated fats and trans fats in food.

There is a diversity of fats with various levels of solid fats found in food products. One such instance of this is the Oreo® Cookie, where there is the regular Oreo® and the reduced-fat version. There are also Oreo®-like cookies with no solid, hydrogenated fats present.

With the current consumer concerns with low fat and no-trans fat foods, the potential for fraud exists by mislabeling foods that incorporate cheaper and less healthy fats.

Fats are extremely complex materials, and the analysis can be complicated for several reasons. Part of this complexity is because fats can manifest in both crystalline and amorphous forms. This can be complicated further by the presence of polymorphic melting forms of a given fat. A polymorph is an unstable melting form that can be carefully managed by processing.

Various polymorphic forms are occasionally desired to acquire a specific texture for the fat. For instance, the fat found in cocoa butter used in chocolates has six polymorphic forms, and only one of them produces the "melt in your mouth" feel.

The successful analysis of fats in foods necessitates a DSC with high sensitivity and high resolution.

The resolution performance aspect is crucial to separate out the glass transition (Tg) and the various melting events associated with fats and possible polymorphic forms. The DSC with the optimal resolution and sensitivity performance readily available is the Power Compensation DSC from PerkinElmer

Power Compensation DSC

The optimal DSC for the classification of foods and fats is the Power Compensation or double furnace DSC. The extremely low mass furnaces offer low thermal inertia and the quickest response time of any DSC instrument on the market. This enables the optimal peak definition and separation of peaks that overlap with any commercially available DSC.

The Power Compensation DSC harnesses two independently controlled, ultra-low mass furnaces (mass of 1 g) in the development of the DSC cell. The extremely low mass offers low thermal inertia and an extremely fast DSC response time, which is crucial for high resolution.

Comparatively, heat flux DSCs or Boersma DTAs, with their greater furnace or those utilizing a large silver block, have more lethargic responsiveness.

This can be adapted to a higher intrinsic thermal inertia and a delayed DSC response time. The resolution from DSC instruments with a large mass furnace is not as good as the Power Compensation DSC.

Some instrument companies try to compensate for the issues caused by using a large silver block with algorithms. These algorithms try to modify the data to account for the reduced response time of that type of DSC cell.

However, there are issues surrounding such treatments since this changes the actual heat flow results.

The Double Furnace or Power Compensation DSC offers a true sample response predicated on actual DSC hardware as opposed to the mathematical manipulation of results. Throughout this study, the fats affiliated with three various fillings of cookies were assessed:

- Regular Oreo®

- Reduced fat Oreo®

- Oreo®-like cookie with no hydrogenated (solid) fats

Experimental

To analyze the fillings of the three different cookies, the following experimental conditions were used. The DSC was calibrated for temperature and enthalpic responses utilizing high purity indium metal.

Table 1. Experimental conditions. Source: PerkinElmer Food Safety and Quality

| . |

. |

| Instrument |

Pyris™ Power Compensation DSC |

| Cooling |

Intracooler II |

| Sample Pan |

Open aluminum pan |

| Sample Mass |

Approximately 11 mg |

| Temperature Range |

-60 °C to 100 °C |

| Heating Rate |

20 °C/min |

| Purge Gas |

Nitrogen |

Results

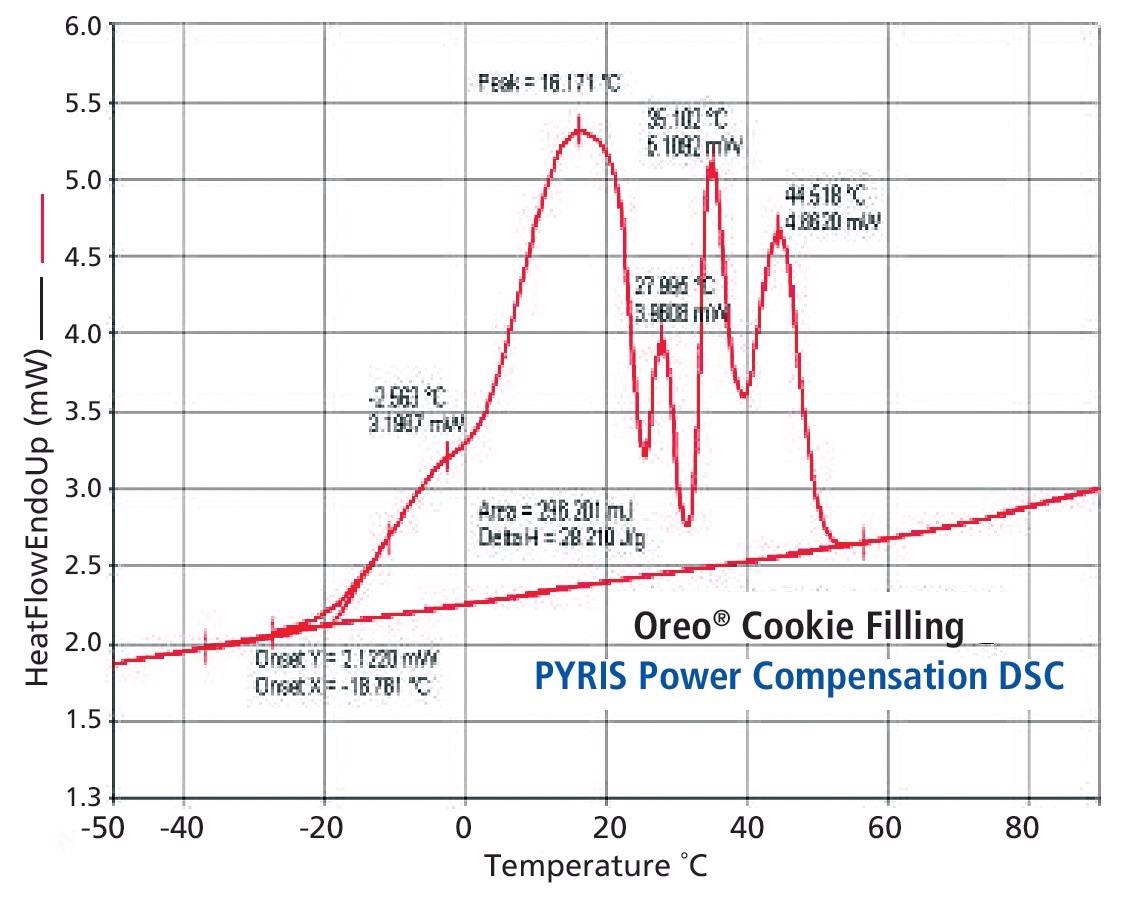

Figure 1 exhibits the DSC results produced for the filling of the regular Oreo® cookie.

Figure 1. DSC results for regular Oreo® cookie filling. Image Credit: PerkinElmer Food Safety and Quality

The plot highlights the DSC heat flow as a function of sample temperature. The sample generates a complex DSC thermograph according to the nature of the fats and polymorphic forms affiliated with the as-received Oreo® cookie filling.

The fat experiences melting beginning at –18.8 ˚C. A series of melting peaks are seen at –2.6 ˚C, 16.1, 28.0, 35.1 and 44.5 ˚C for the fats in the filling. The intricate melting spectrum reflects the presence of polymorphic forms because of specific processing conditions used to make the Oreo® filling.

The total heat of melting of the cookie filling is found to be 28.2 J/g. The DSC results show that a significant amount of the fat in the Oreo® cookie filling melts above room temperature and this behavior is due to the hydrogenated fats in the filling.

The High-Resolution Response of the Pyris™ Power

Compensation DSC is essential for detecting the multiple peaks associated with the polymorphic forms of the cookie filling, even at the rapid heating rate of 20 ˚C/min.

Heat flux DSC instruments, particularly those utilizing a huge silver block, would typically smear out the different transitions affiliated with the fats and polymorphic forms in the filling, making the classification less definitive and incomplete.

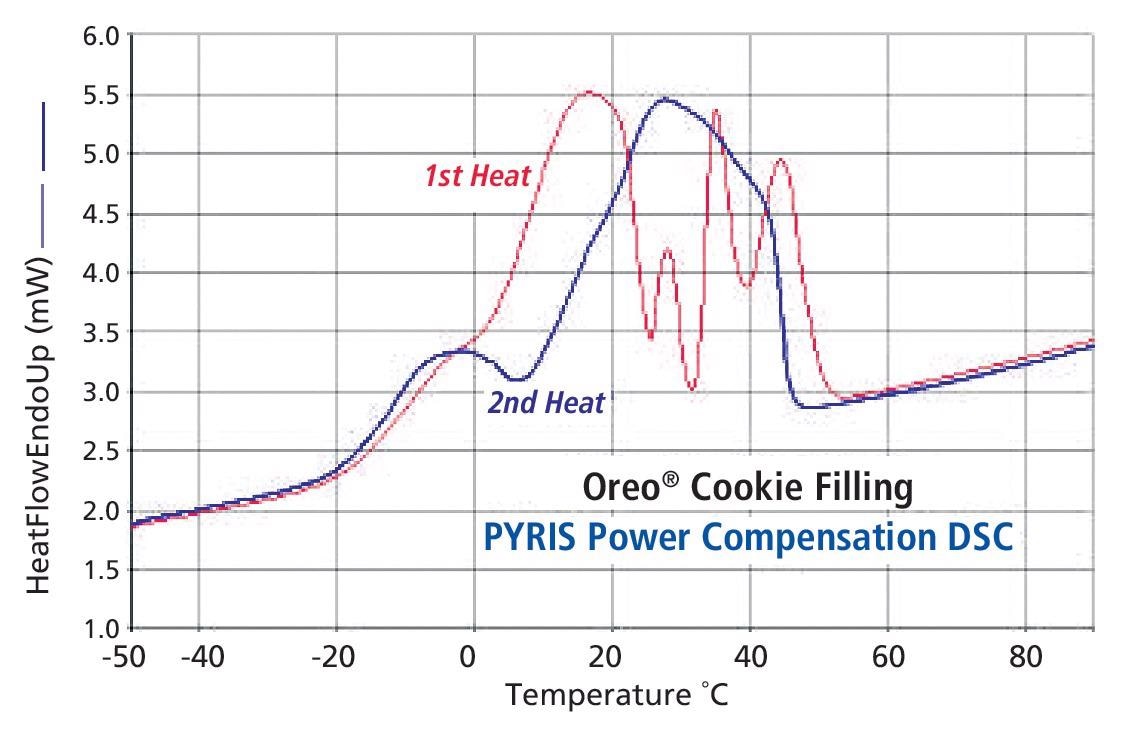

With the Pyris™ Power Compensation DSC, all the key transitions, both small and large, are seen. The regular Oreo® cookie filling was reheated at 20 ˚C/min after being cooled back to –60 ˚C. The results of the reheat experiment are exhibited in Figure 2.

Figure 2. Comparison of first and second DSC heats for filling. Image Credit: PerkinElmer Food Safety and Quality

The filling now demonstrates a very different thermal response, and this signifies the differences due to thermal history. Melting, cooling and reheating yields a new morphology or structure in the fat. DSC is a useful technique for studying the impact of thermal history on fats and their polymorphic forms.

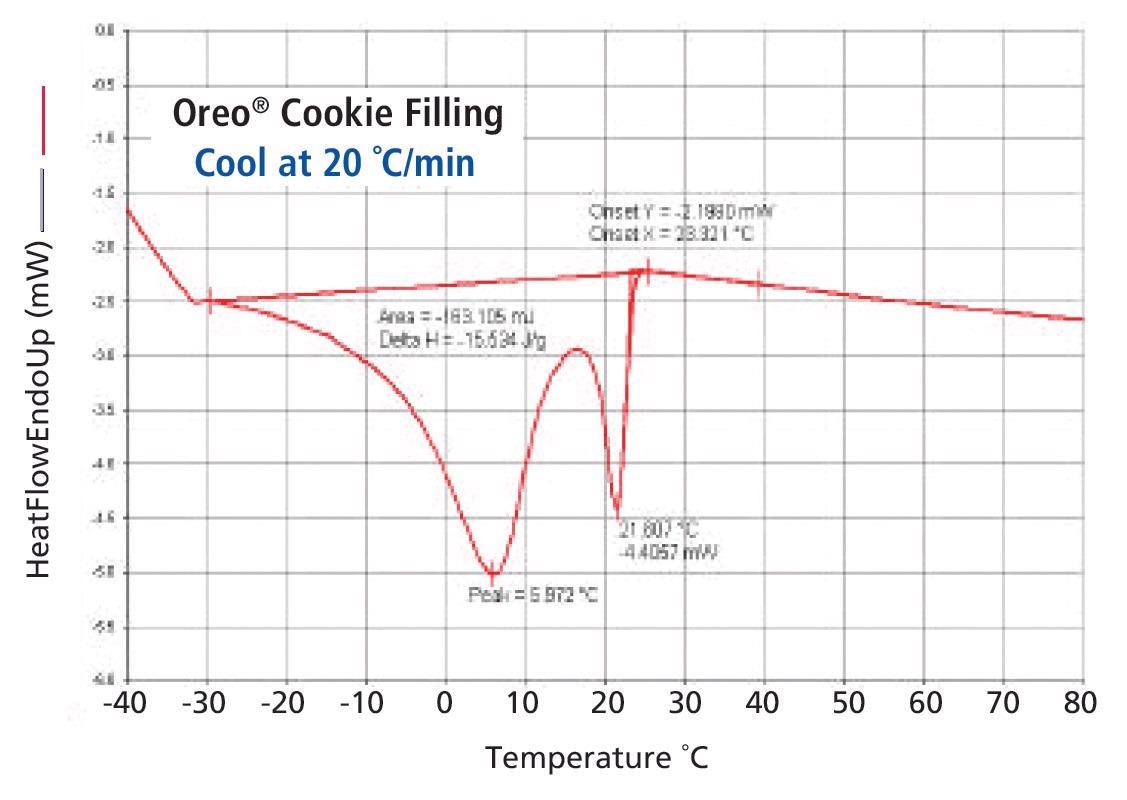

The Power Compensation DSC also offers exceptional results during cooling experiments. Fats produce well-defined crystallization events throughout cooling, and this information is important for classification and process control purposes.

Figure 3 exhibits the DSC results acquired by cooling the Oreo® cookie filling from 100 to –60 ˚C at a rate of 20 ˚C/min.

Figure 3. DSC cooling results for Oreo® cookie filling. Image Credit: PerkinElmer Food Safety and Quality

The crystallization of a fat component takes place abruptly at 23 ˚C. The cooling data indicates two different crystallizable fats in the cookie filling. The DSC results acquired for the reduced fat Oreo® cookie filling are shown in Figure 4.

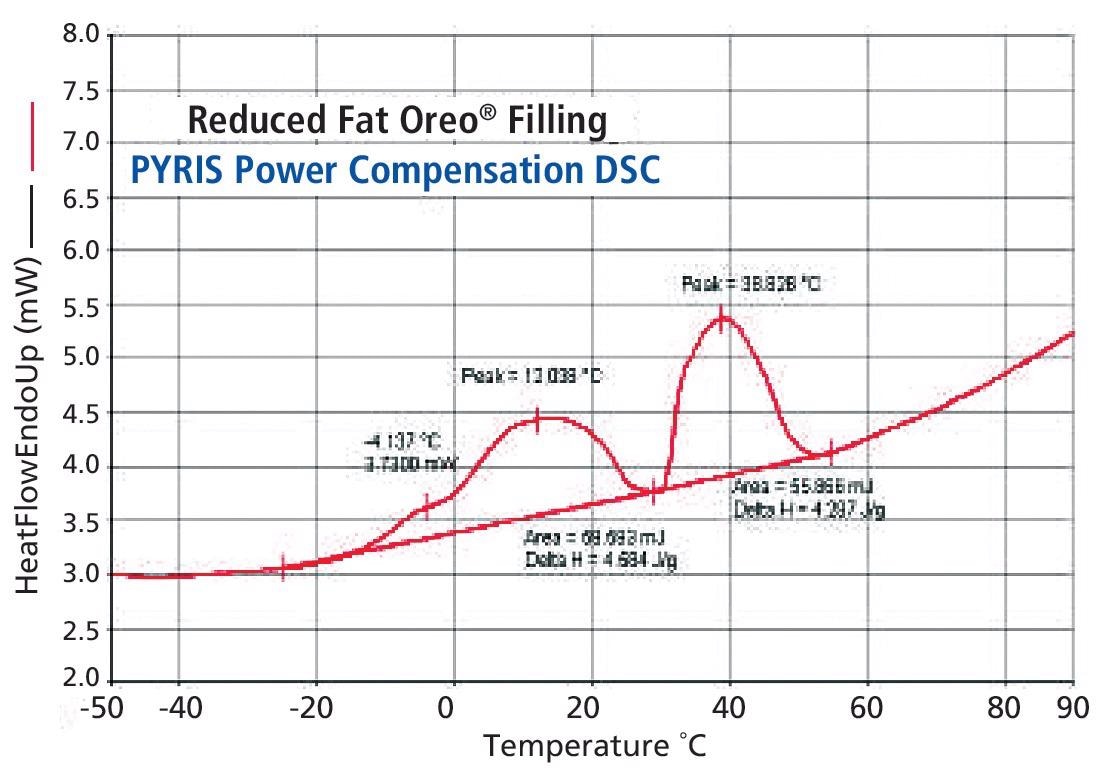

Figure 4. DSC results for reduced fat Oreo® cookie filling. Image Credit: PerkinElmer Food Safety and Quality

This filling experiences multiple melting transitions at –4.1 ˚C, 12.0 and 38.8 ˚C. Although the reduced fat filling is made up of solid or hydrogenated fats, the amount of fat is reduced, as indicated by the lower values of the melting points.

For a total heat of 8.9 J/g the first and second melting transition generates heats of melting of 4.6 and 4.3 J/g, respectively. This is far less than the value identified for the regular Oreo® cookie filling (28.2 J/g).

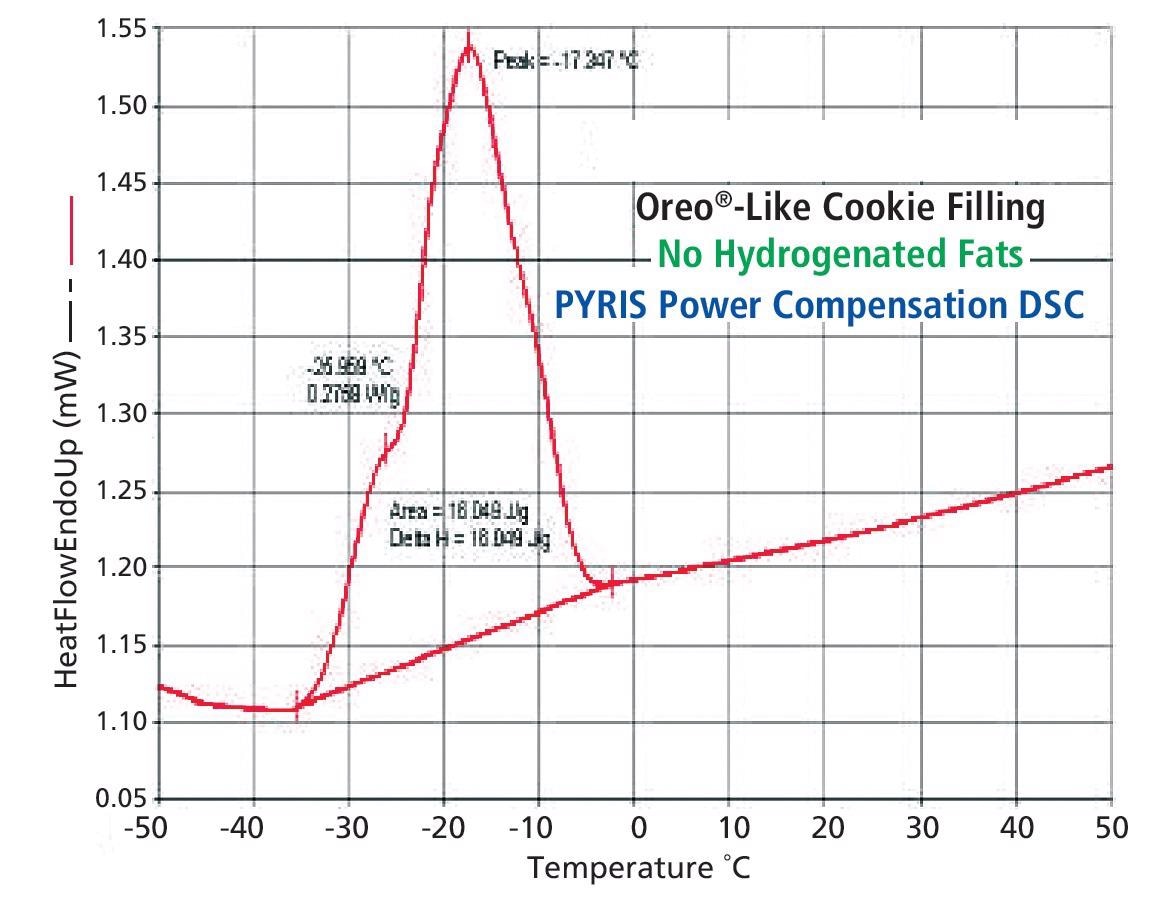

The Oreo®-like cookie includes a filling with no solid or hydrogenated fats, and the DSC results for this sample are displayed in Figure 5. The complete melting of the fat in this filling occurs below 0 ˚C, with melting peaks appearing at –26.0 and –17.3 ˚C.

Figure 5. DSC results for Oreo®-like cookie filling (no hydrogenated fats). Image Credit: PerkinElmer Food Safety and Quality

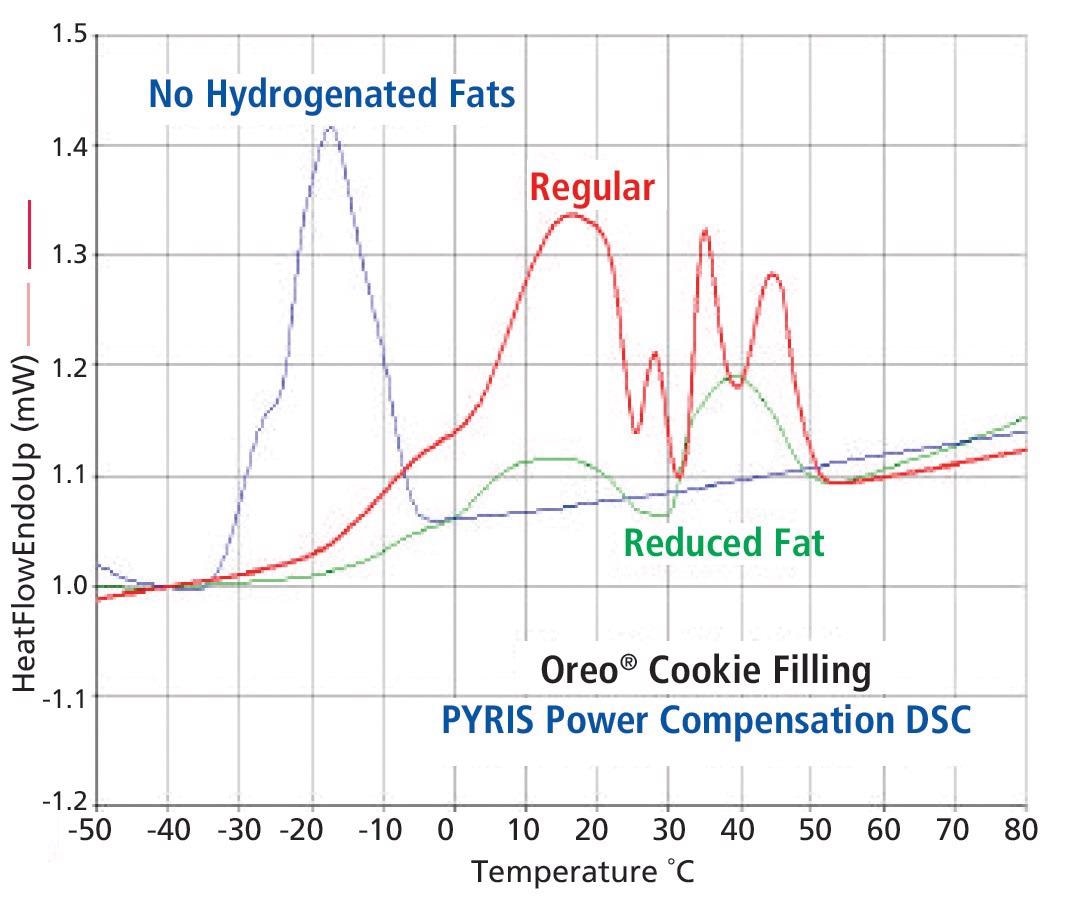

The total heat of melting for the non-hydrogenated fat filling is 16.1 J/g. Figure 6 exhibits a direct overlay of the DSC results acquired for the three different cookie fillings. The variations in the melting responses of the fats from each of the fillings are clearly seen in these results.

Figure 6. Overlay of DSC results for regular Oreo®, reduced fat and non-hydrogenated fillings. Image Credit: PerkinElmer Food Safety and Quality

Summary

The Power Compensation or double furnace DSC produces exceptional results for foods, including the fat nature and content. The fast responsiveness of the Power Compensation DSC offers the greatest possible resolution, and this is vital for classifying the various polymorphic melting forms affiliated with fats in foods.

Even at the rapid heating rate of 20 ˚C/min, the Power Compensation DSC has the capacity to deliver high-resolution to be able to identify the numerous melting peaks of the polymorphic forms for the as-received Oreo® cookie filling.

This data is crucial for the complete characterization of the food fats, product uniformity, quality assurance and process control purposes.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.