The 3D printing composites industry will be worth $2 billion within the next decade, with the printing of fiber-reinforced polymers set to be one of the most interesting and impactful areas, states a new report.

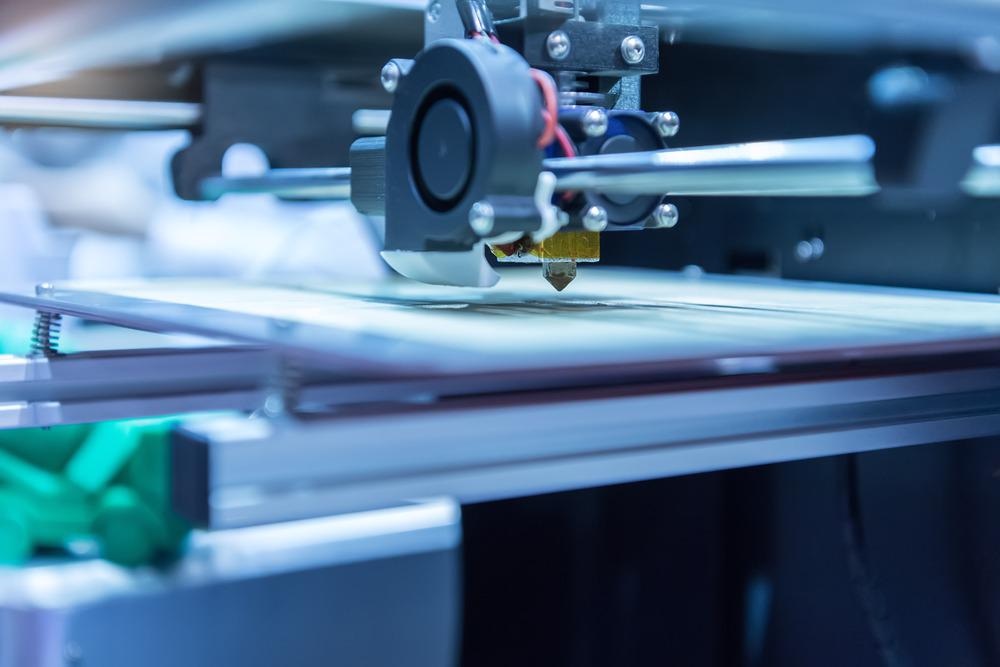

Image Credit: asharkyu/Shutterstock.com

Also known as additive manufacturing, 3D printing builds an object up layer-by-layer using a computer design, but these objects have mechanical limitations that could be solved by fiber reinforcement. The alternative - composite manufacturing - is expensive compared to the rapid prototype, moldless and automated approach offered by 3D printing.

Printing Composites

The market for fiber-reinforced polymers (FRP) is dominated by glass fibers and carbon fiber thermoplastics. 3D printing of thermoplastic composites is the most established technology and uses a variation of fused filament fabrication (FFF), in which a continuous filament of thermoplastic is fed from a large spool through a moving extruder and printed onto the growing item.

The technology is nothing new, but it has taken time to develop and is only now reaching commercial maturity.

When 3D printing composites, there are many factors that affect the outcome, including the material – continuous fiber versus chopped fibers, or thermoplastic versus thermoset for example, and the printer properties that make it suitable for an industrial outfit or a desktop device for a prosumer, or hobbyist.

It is, therefore, necessary to understand the market potential, technology differentiation, pain points and limitations, and the market status, which are all explored in a new report from IDTechEx, 3D Printing Composites 2021-2031: Technology and Market Analysis.

There are many emerging technological developments according to the report - from those realizing chopped fiber alignment in a photopolymer to high-throughput, multi-axis printers, to larger scales and increasing fiber contents.

These should be compared to incumbent technology and developments occurring in the automated manufacturing of composite materials, it states, from AFP and ATL processes, through to pick-and-place robots for organosheets.

The Market

Key to the industry are the materials used as these dictate the printer requirements and part properties and are central to the competitive business models used. The end goal for many are continuous fiber composites, but there are many opportunities for their shorter counterparts and thermoset and thermoplastic resins alike.

The technology can be used to replace metal parts, or as a more economical way to make existing composite parts, via tooling, prototyping, or low-volume part production. The most common use is in tools, jigs, and fixtures – a growing and potentially lucrative area - which allows manufacturers to differentiate and expedite their processes or bring certain capabilities in-house.

Despite its many advantages, additive manufacturing has often been limited by production rate, availability of material, and scale. This is not likely to change for composite printers, but the technology applications are increasing with interest from the energy, aerospace and defense, space, marine, medical, automotive, and motorsport industries.

The Future

3D printing of fiber-reinforced polymers is reaching a commercial tipping point, says the report. Over the next ten years, installed base and applications will grow, and technology will mature, with new materials and printers making their way to market and new distribution partners joining the game.

There are barriers to adoption that need to be overcome, in addition to the establishment of supply chains and digital infrastructure and, according to the report, the inevitable consolidation in the number of manufacturers.

While most of the activity in 3D printing composites is in the US, key markets are emerging and are expected to grow in Europe and Asia thanks to an increasingly competitive market.

Strategic partnerships are being established between emerging hardware manufacturers and major chemical companies, with numerous other companies entering the area directly by launching filaments or composite materials. Others are developing proprietary technology and using it in-house, becoming a service provider, contract manufacturer, or selling directly to the consumer.

References and Further Reading

Collins, R. (2021) 3D Printing Composites 2021-2031: Technology and Market Analysis, IDTechEx - https://www.idtechex.com/en/research-report/3d-printing-composites-2021-2031-technology-and-market-analysis/827. Accessed 2nd August 2021.

Collins, R. (2021) 3D Printing Composites Will be a $2bn Industry Within the Next Decade, IDTechEx - https://www.idtechex.com/en/research-article/3d-printing-composites-will-be-a-2bn-industry-within-the-next-decade/24303. Accessed 2nd August 2021.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.