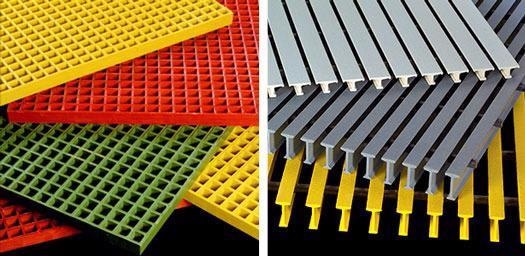

Floor grating is frequently utilized where flooring is subject to extreme corrosion or in place of flat surfaces for industrial applications. It is most commonly associated with raised catwalks and bridges, but grating made up of parallel bars of reinforced plastic is utilized in recreational water parks across the globe.

Image Credit: Strongwell Corporation

All of these areas are associated with high volumes of worker and pedestrian traffic, leading to a good degree of strength to resist potential failure and deformation.

For commercial and industrial settings, steel and aluminum are standout structural materials due to their good resistance to different loading forces and non-corrosivity.

Yet, fiberglass grating is clearly superior when considering weight as well as strength, impact resistance, slip resistance and overall response to static and dynamic loads.

Load Resistance of Fiberglass Gratings

A load is any static or dynamic force applied to a structural element that could cause it to irreversibly or plastically deform. Construction loads define the weight of materials that may act on the structural framework; for example, the weight of pedestrian foot traffic on a bridge.

There are two key reasons why fiberglass grating is designed with good all-round load resistance; configuration of both parallel bar and mesh grating components combined with the inherent strength of fiber reinforced plastics (FRP).

DURADEK® systems are made up of parallel pultruded bars which are connected by high-strength cross-rods for good overall stability. While DURAGRATE® fiberglass grating is a molded mesh flooring choice with bidirectional load bearing, which means applied loads are distributed multi-directionally through perpendicular bearings.

Each configuration supplies a high uniform load-resistance solution for both industrial and commercial flooring applications. Below outlines how fiberglass gratings hold up under more complex loading phenomena.

What is a Concentrated Load?

Concentrated loads are focused upon a very small section of a structure’s surface, unlike a distributed load which acts upon a comparatively large cross-sectional area. Although a concentrated load is sometimes described as a load that acts on a single point, realistically, all loads are applied over an area, however finite.

A concentrated load is defined as a loading stressor which is acting on a very small area. The two key factors of concentrated loads in fiberglass grating design are location and magnitude.

Image Credit: Strongwell Corporation

How Severe is the Force and Where Will it Be Applied?

High concentrated loads can result in grating cross-sections bending or deflecting, which is in turn determined by a number of material properties and structures.

The intrinsic strength of fiberglass provides it with exceptional resistance to high loading forces, but it is the unique grating structure that allows this resistance to perform versus concentrated loads at different points along the framework.

Structural engineers are able to specify lightweight fiberglass gratings capable of withstanding multiple pounds per foot of width in concentrated weight with a negligible deflection by supporting fiberglass bearings with transverse cross-rods, or distributing loads bi-directionally.

In summary, fiberglass grating performs extremely well under concentrated loads and can be carefully engineered for even better performance under more strenuous conditions, like industrial flooring designed to handle heavy wheel traffic.

Strongwell’s Fiberglass Gratings

Strongwell provides a range of resources and detailed design brochures to help customers select the right fiberglass solution for their application.

This information has been sourced, reviewed and adapted from materials provided by Strongwell Corporation.

For more information on this source, please visit Strongwell Corporation.