Plastic’s versatile, durable, low-cost and lightweight characteristics are part of why we now depend on it in our everyday lives. From packaging food and medicine to finding use in electronic devices and the cars we drive, plastic is everywhere.

Research highlights that since 1950, more than 8 billion tons of plastic have been produced, with more than 350 million tons of plastic being produced every year.

As society is increasingly becoming aware of the ecological impact of plastic, the industry is hard at work, finding ways to become more sustainable, including slowly introducing bioplastics made from renewable materials and expanding the amount of recycled plastic used as feedstock.

Image Credit: Hitachi High-Tech Analytical Science

Why Testing in Plastic Process and Quality Control is Important

The plastic lifecycle is not straightforward; when a plastic product reaches the end of its life, it can be reused, repaired or recycled in two main ways.

The first is mechanical recycling, where plastics are broken down without changing their chemical structure. They can then be (re)used to produce new items. On the other hand, chemical recycling transforms the used plastics into their basic (monomer) building blocks where they are ready to use as raw material feedstock.

Testing plays a critical part in the characterization of both virgin raw material and recycled plastics, ensuring the optimization of the production process to limit waste. Testing also guarantees that the plastic has the appropriate composition for the required application and that no undesirable or toxic elements are present in compliance with particular directives.

A number of analysis techniques can be deployed throughout the testing process, from a straightforward visual inspection to intense chromatography techniques.

X-ray fluorescence (XRF) is a great example as it is entirely non-destructive, can be used on solids, powders, pellets and liquids and offers rapid, detailed elemental composition results (within minutes) with little to no sample preparation.

XRF for Plastics Process and Quality Control

XRF can support plastics process and quality control over the lifecycle. This article takes a detailed look at how.

Catalyst Monitoring in Polymerization Process

To begin the lifecycle, raw materials (natural gas or oil) are first processed into monomers. Next, these monomers are polymerized into the right type of plastic. Catalysts are introduced to the polymerization process to expedite the reaction and make sure the material is completely transformed.

XRF is employed to identify the level of catalyst in the base polymer. This allows the process engineer to track the status of the reaction, tell whether the reaction is complete and ensure the product is safe to use.

Example: Catalyst Level in PTA

During the production of high-performance plastics, such as polyethylene terephthalate (PET), purified terephthalic acid (PTA) is used. It is acquired via the oxidation of xylene in the presence of acetic acid, a catalyst (solution comprised of cobalt and manganese), and a reaction promoter (hydrobromic acid).

All these are combined, and the levels of catalyst and reaction promoter are tracked to make sure the reaction is complete.

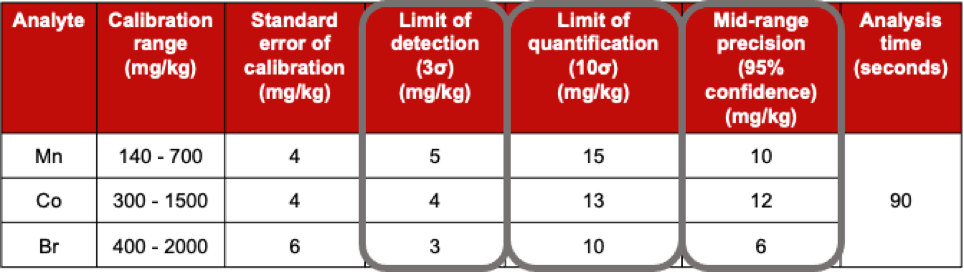

Table 1. Source: Hitachi High-Tech Analytical Science

The above table exhibits the results taken with Hitachi’s X-Supreme 8000 EDXRF analyzer. The three catalyst elements were simultaneously identified in a 90-second scan. The limit of detection is the amount of a particular element that the instrument can detect above the background signal.

This is below the limit of quantification, which is the lowest possible limit that can be measured with a decent degree of accuracy and precision – this value is extremely important.

The limit of quantification for these elements is exceptionally low, even within such a short analysis time. This provides operators with the ability to react quickly should the process need modifying.

Verifying Additive Level in Polymers

The next step in the process is the introduction of chemicals to the virgin polymer. These additives provide plastics with the specific properties needed for their final processing and application. XRF is employed here to monitor the presence of the additives and that they are at the intended levels.

Example: Titanium Oxide Additive in PET

Titanium dioxide is introduced as a pigment. It is extensively used in plastics production as it is very good at scattering visible light, absorbing UV and giving whiteness, brightness and opacity to plastics such as PET. It is critical that the right amount of TiO2 is added to meet certain specifications.

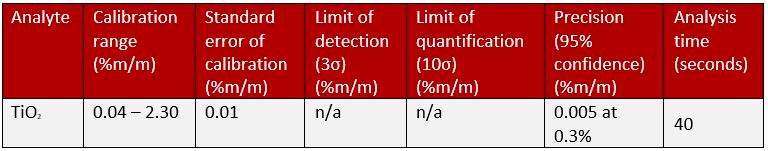

Table 2. Source: Hitachi High-Tech Analytical Science

The data in the table above displays the results for TiO2 captured using the LAB-X5000 benchtop XRF analyzer. In just 40 seconds, the instrument offers extremely accurate readings for the pigment content, guaranteeing consistency in the product’s quality batch after batch.

Meeting Legislation: Checking for Hazardous Substances

XRF analysis can also check if raw materials and finished products comply with the Restriction of Hazardous Substance (RoHS) Directive.

XRF is not employed to certify a product for RoHS compliance, but it is a useful and recognized technique for screening incoming goods and polymer feedstock. When used in this way, it can limit the amount of laboratory analysis necessary, reducing costs and saving time.

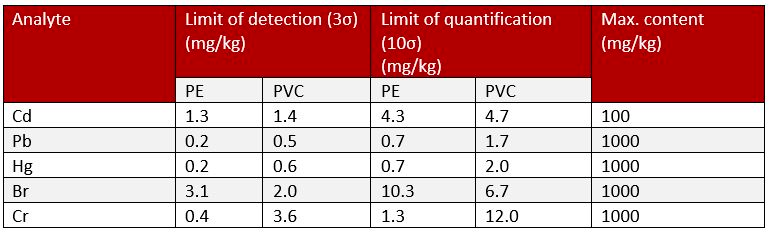

Table 3. Source: Hitachi High-Tech Analytical Science

The table above displays XRF results for the five elements that fall under international standard IEC 62321. Using XRF, it is possible to quantify all five elements in just 30 minutes and ensure they are below the acceptable limits.

Any products that are close to or exceed the limit can be subjected to lab analysis by inductively coupled plasma (ICP) or atomic absorption (AA) spectrometry. Hitachi offers a range of XRF analyzers designed for RoHS analysis.

These are just three ways XRF can be used in plastic production processes and quality control and the recycling of plastics. There are also other applications, such as sorting types of plastic by type ready for recycling.

Hitachi XRF instruments are manufactured to function in harsh environments; they are safe to use, robust, durable, and stable. They have been designed to deliver excellent results for many years, making them a sound investment.

To discover more about XRF for plastics production and recycling, watch Hitachi’s on-demand webinar or get in touch with one of the company’s experts to learn more or arrange a demonstration.

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Analytical Science.

For more information on this source, please visit Hitachi High-Tech Analytical Science.