In this interview, AzoM talks to Mark Warner and Ryan Ervin from Hardinge about the insights of processes automation via robotics utilization across the manufacturing industry. Process automation offers precise execution of manufacturing through self-correction.

What is process automation, and how can it benefit the manufacturing industry?

“Process automation” refers to the streamlining of the entire manufacturing process from start to finish by ensuring that the machining of a part is repeatedly done with the utmost precision and with minimal human input, thus ensuring accuracy through self-correction, and allowing the implementation of robotics in their fullest potential utilization.

Why is precision, particularly in part manufacturing, important?

Precision dictates how effectively process automation can be implemented; in particular, through self-correction, stability, and the ultimate accuracy of both the machine and the process. The more precise the machine tool and supporting accessories, the better chance you have for the process to be automated.

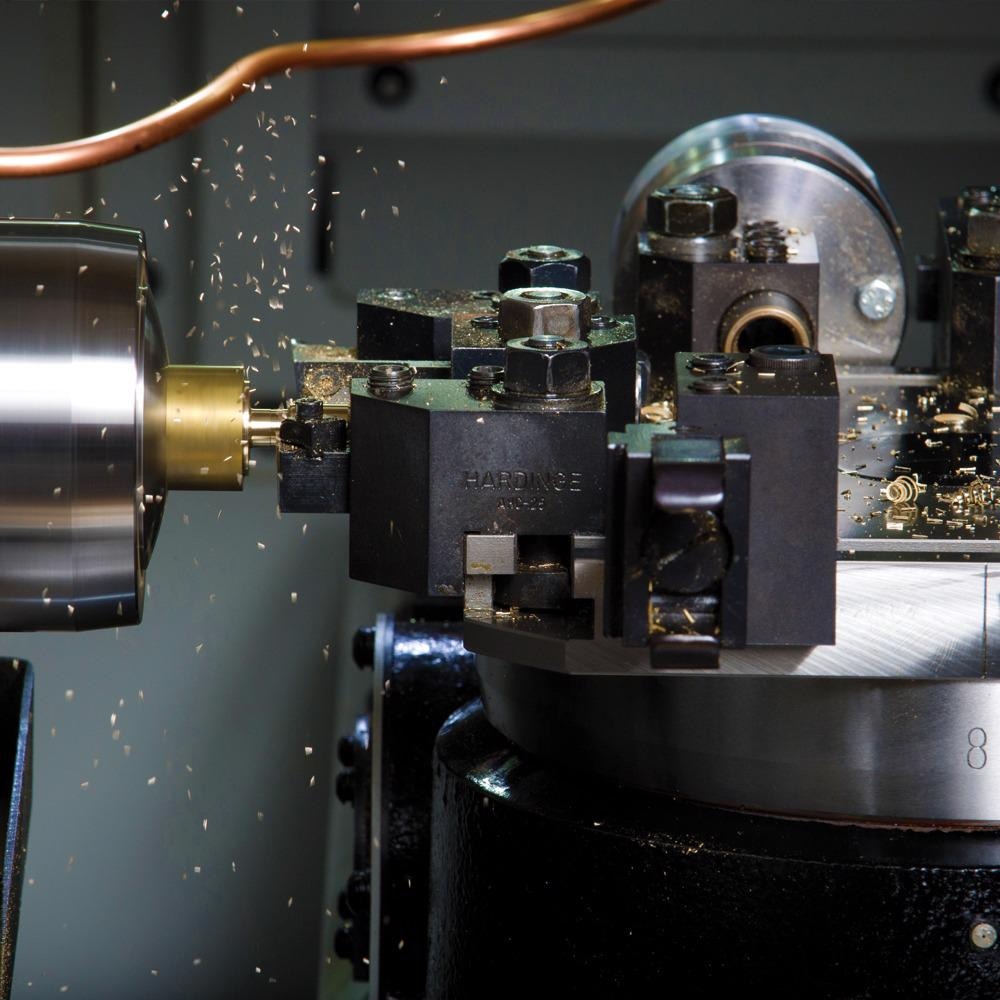

Image Credit: HARDINGE

What challenges does the manufacturing industry face, and what solutions are available to address them?

Some of the challenges faced by the industry are a lack of experienced machine operators and programmers as a result of the COVID-19 pandemic. Additionally, a shift to industrywide automation in order to manufacture in greater volume with higher accuracy has led to a massive increase in demand for solutions without human input. In response to these challenges, process automation has become a primary solution.

How does the Hardinge Super-Precision T Series provide highly accurate parts off a production turning center, and what are the key advantages?

Hardinge Super-Precision T machines are designed to be the most precise production turning center in the market, but without the compromise of either functionality or capability as opposed to competitors’ offerings. Whereas other machines compromise between capability or function, Hardinge’s machines have it all. Hardinge Super-Precision machines are just as functional as every other machine, but with accuracy far surpassing that of the competition. This is achieved using high-end components, superior engineering and design, and the stability of the base.

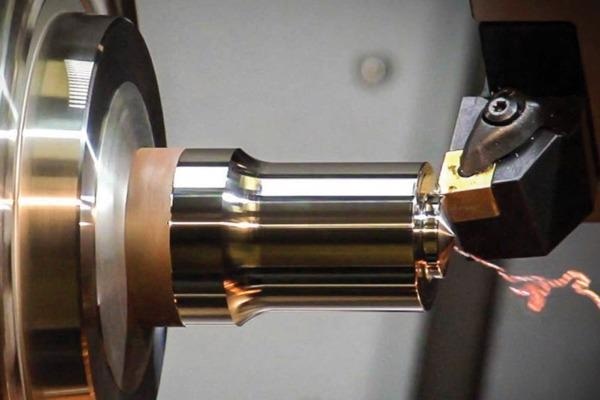

Image Credit: HARDINGE, SUPER-PRECISION T Series

Can you describe your Grinding Systems and how does Hardinge ensure optimal production output?

In aligning with the Hardinge philosophy, we design functionality that gives end users the ideal manufacturing platform that is required without compromising on capability. The manufacturing platform also ties into process automation by being able to accurately repeat the manufacturing process with minimal human input from start to finish. Our high-resolution vision systems, tool laser measuring technologies, high-resolution probing and measurement systems for automated machining, fully integrated 5-Axis control architecture, industry-leading hydrostatic B/B1 axes swiveling technology, multi-spindle technology on same machine platform, automatic tool change spindles (ATC), integrated 20-position tool changers, and flexible wheel dressings, among countless other industry-leading features, all work together to create a robust and versatile manufacturing platform for a world of high-precision automation.

How do Hardinge products streamline the visual inspection process of part manufacturing?

Hardinge products streamline the visual inspection process through probing, vision systems and onboard imaging. These features provide the security of knowing that the part is good and in-spec every time, before it ever comes out of the machine.

Image Credit: HARDINGE

With less human input, how are manufacturing processes made more efficient?

Optimal manufacturing processes allow elevated efficiency through automation, Iiot (monitioring), prediction, and self-correction. Additionally, through these innovative systems, the more machines a person can operate, the less people are required overall without compromising on performance or quality.

Image Credit: HARDINGE, The Conquest® H51 Super-Precision bar machine

What are some tangible examples of how these systems can be applied in manufacturing?

These systems innovations can be realized in real-world applications where high-precision requirements in mid- to high-volume productions that have longer cycle times due to their complexity. In particular, these innovations are particularly evident in manufacturing industries including, but not limited to medical, aerospace, semiconductior, automotive, and defense.

About Ryan Ervin and Mark Warner

Ryan Ervin has been with Hardinge, Inc. for over thirteen years, and has extensive knowledge of the manufacturing industry in every capacity. He currently serves as the Vice President of Sales and Marketing. Mark Warner serves as the Regional Marketing Specialist for North America at Hardinge, and he has worked extensively in the manufacturing industry for nearly a decade. Mark and Ryan are excited to explore for the new opportunities and challenges that automation will bring to manufacturing processes, and how Hardinge will continue to be an industry leader for the next generation of manufacturing

This information has been sourced, reviewed and adapted from materials provided by Hardinge Inc.

For more information on this source, please visit Hardinge Inc.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.