Metal additive manufacturing can produce a wide range of metals, but additive manufacturing with aluminum is used to develop parts specifically for the aerospace and automobile industry. This article explores production methods, advantages, and applications.

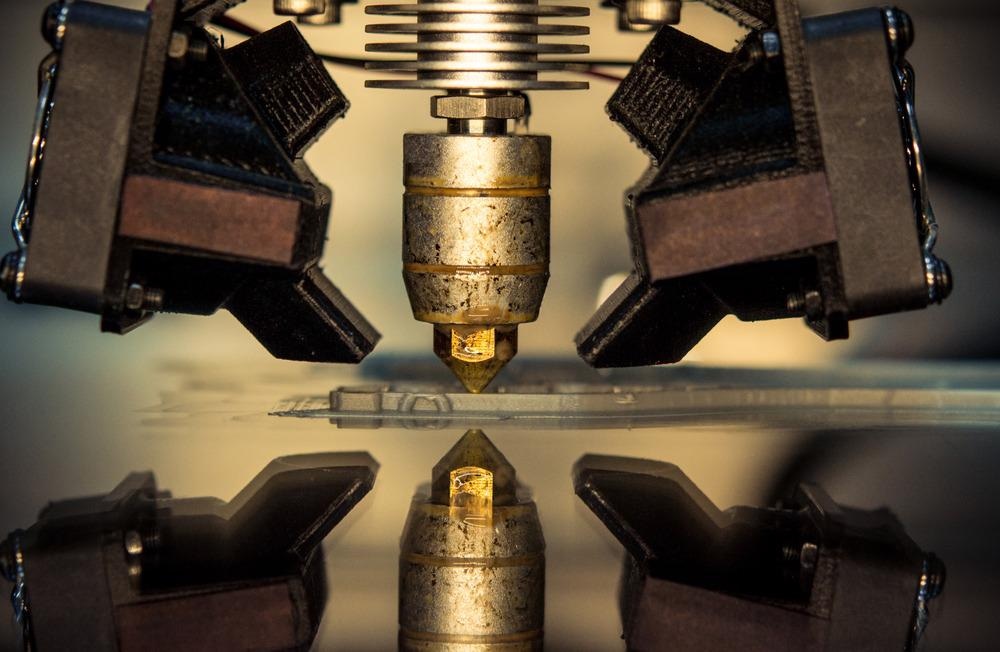

Image Credit: MarinaGrigorivna/Shutterstock.com

Three-dimensional (3D) printing (also known as additive manufacturing) produces parts from digital models using a layer-by-layer material build-up approach. 3D printing is widely used in the production of polymers, metals, concrete, and hydrogels.

In particular, metal additive manufacturing has gained significant attention due to its advantages over conventional manufacturing methods such as casting, forming, and machining.

Metal additive manufacturing is used in aerospace, oil and gas, marine, and automobile industries due to advantages such as freedom of part design, component complexity, being lightweight, part consolidation, and design for function. Additionally, additive manufacturing is a tool-less manufacturing technology that can produce fully dense metallic objects with high precision in a smaller period.

Methods Used in Aluminum 3D Printing

Laser powder bed fusion (LPBF) is a method used to 3D print aluminum with a higher surface finish and high accuracy. This process is initiated by localized melting of material using a powerful laser, followed by the development of a successive layer of solidified metal. In this technique, the material and the part supports are generated concurrently and based on the properties of the aluminum-based alloy, the process parameter can be modified to adjust porosity, microstructure, and final material properties.

Electron beam powder bed fusion is a method similar to LPBF in which an electron beam is used to solidify the metal powder. Due to the electron beam's high processing temperature, the single layers of the 3D-printed parts cool gradually, resulting in a coarser microstructure compared with LPBF.

Aluminum Alloys Used in 3D Printing

AlSi10Mg is a commonly used aluminum alloy for the industrial application of 3D-printed aluminum. Its advantages are high strength, toughness, dynamic qualities, improved thermal characteristics, and buildability.

AlSi7Mg is another high-strength steel alloy employed in structural components of aerospace, defense, and automobile industries. The main advantages of 3D-printed AlSi7Mg are its lightweight, corrosion resistance, and high dynamic load-bearing capability.

In addition, certain studies have demonstrated successful printing of Al 6061 and Al 7075, which were previously thought to be incompatible with the metal additive manufacturing methods.

Recent Research on 3D Printed Aluminum

In a recent study published in the journal Ceramics, researchers from China used the direct ink writing method to print aluminum-phosphate-bonded Al2O3 ceramic. Their main finding was that Al2O3 ceramic exhibited ultra-low dimensional shrinkage due to the addition of the inorganic binder.

Recent studies have explored the 3D printed composite sandwich structure of aluminum for application in the aerospace industry. 3D printing of the composite sandwich structure can improve sustainability and manufacturing flexibility in the aerospace industry.

Further Reading: The Role of Pellet Extruders in 3D Printing

The addition of nanomaterials into aluminum is also a recent topic of research in metal 3D printing. Nanomaterials improve the mechanical and thermal properties of 3D printed aluminum and the fusion of nanoparticles during the 3D printing process improves the properties of 3D printed aluminum.

Advantages of Aluminum 3D Printing

The advantage of aluminum 3D printing is that the mechanical properties of aluminum can be modified by changing the microstructure and the internal distribution of forces. Studies on aluminum 3D printing have also demonstrated material savings compared to conventional methods. High-tech industries that use metal additive manufacturing have demonstrated the faster fabrication of complex components, improved material strength, and ductility advantages than conventional methods.

Aluminum additive manufacturing also enables the production of highly optimized structures that were otherwise expensive, time demanding, or even impossible to fabricate using conventional manufacturing methods. Additionally, 3D printed aluminum parts can be used with other parts to create hybrid structures.

Using aluminum 3D printing, it is also possible to fabricate structural sections with energy-absorbing qualities with internal reinforcing features. Moreover, undesirable residual stresses developed in structural applications can be converted to advantageous pre-stressing.

Challenges and Future Scope of Aluminum 3D Printing

There are still significant challenges with regard to the 3D printing of aluminum for multiple industrial applications. In some instances, 3D printing of aluminum is more expensive than conventional production methods. In metal 3D printing, existing design methodologies must be modified to adapt to material properties and variable geometry changes.

Metal additive manufacturing techniques will need to be more standardized, and new quality assurance procedures need to be implemented to ensure that manufactured parts are reliable during their life cycle. Aluminum 3D printing has significant potential for application in various industries, provided these technical and industrial challenges are resolved.

References and Further Reading

Zengrong Hu, Feng Chen, Jiale Xu, Qiong Nian, Dong Lin, Changjun Chen, Xing Zhu, Yao Chen, Min Zhang, 3D printing graphene-aluminum nanocomposites, Journal of Alloys and Compounds, Volume 746, 2018, Pages 269-276, ISSN 0925-8388, https://www.sciencedirect.com/science/article/pii/S0925838818307618?via%3Dihub

Xin Xu, Junyi Zhang, Pan Jiang, Desheng Liu, Xin Jia, Xiaolong Wang, Feng Zhou, Direct ink writing of aluminum-phosphate-bonded Al2O3 ceramic with ultra-low dimensional shrinkage, Ceramics International, Volume 48, Issue 1,2022, Pages 864-871,ISSN 0272 8842, https://doi.org/10.1016/j.ceramint.2021.09.168

Panwisawas, C., Tang, Y.T. & Reed, R.C. Metal 3D printing as a disruptive technology for superalloys. Nat Commun 11, 2327 (2020). https://www.sciencedirect.com/science/article/pii/S0925838818307618?via%3Dihubhttps://doi.org/10.1038/s41467-020-16188-7

A Study on 3D Printing and its Effects on the Future of Transportation. September 2018. https://cait.rutgers.edu/wp-content/uploads/2018/05/cait-utc-nc19-final.pdf

Introduction to metal 3D printing. (n.d.). Hubs. https://www.hubs.com/knowledge-base/introduction-metal-3d-printing/

Erlinde, B. (2020, June 24). How 3D Printing in Aluminum Really Works. 3D Printing Blog | i.Materialise. https://i.materialise.com/blog/en/how-3d-printing-in-aluminum-works/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.