Polystyrene and butadiene can form nano copolymer latex spheres through the process of emulsion polymerization, these spheres have wide industry applications including cement, paper, and other industry areas.

The latex surface, depending on the composition, may take either negative or positive charges that maintain the latex system’s stability. It is therefore critical to measure the zeta potential in order to evaluate charges, which ultimately reveal the stability of the sample.

. Image Credit: Bettersize Instruments Ltd.

The BeNano 90 Zeta (Bettersize Instruments Ltd.) was used in this process to take measurements of the sizes and zeta potentials of polystyrene-butadiene copolymers which are dispersed in aqueous environments that derive from the same source but diverge in manufacturing processes.

Instrumentation

A solid-state laser beam with a wavelength of 671 nm and a power of 50 mW illuminates the sample In the BeNano 90 Zeta, an avalanche photodiode (APD) detector coupled with iber, which is utilized to gather scattered light signals from 12° for zeta potential measurement and 90° for size measurement.

Experiment

In order to obtain size and zeta potential measurements, two copolymer latexes were diluted by 1000 times in pure water.

In order to investigate the repeatability of the results and obtain the standard deviation of the result, each sample was measured at least three times.

Results & Discussion

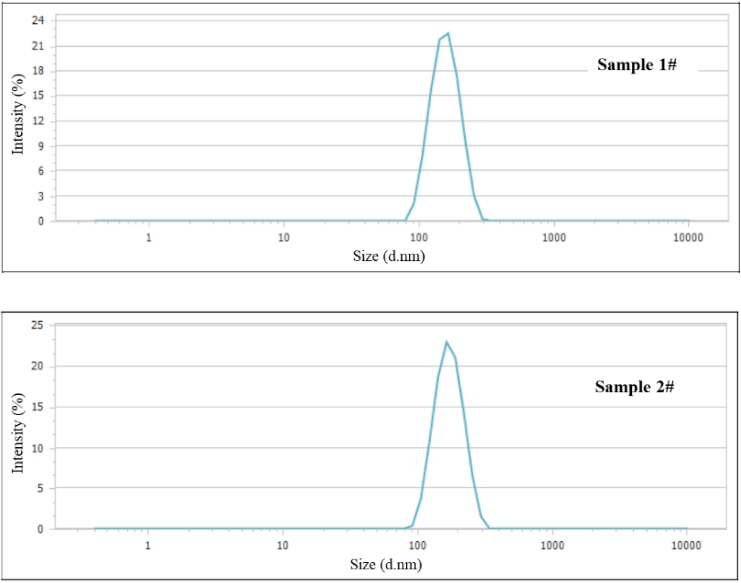

In this experiment, the sizes and zeta potentials of two latex samples were obtained. The size distribution curves of both samples are displayed in Figure 1. As exemplified by Figure 1, it appears that both samples are nano-scaled, with only narrow peaks and without large aggregates.

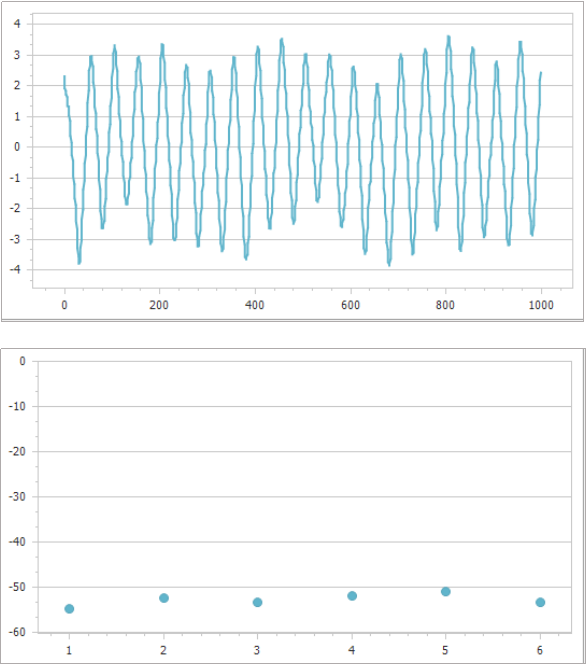

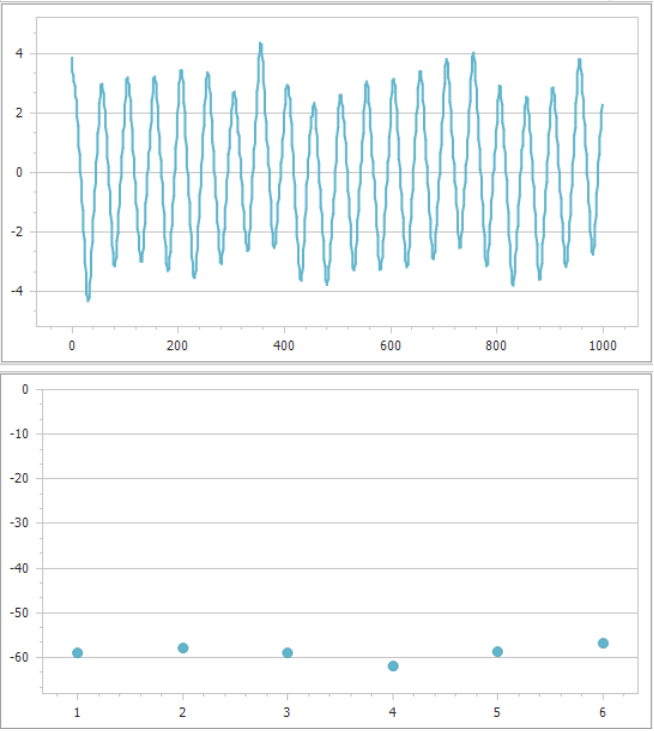

The phase plots and zeta potential trend plots of ELS measurement are displayed in Figure 2 and Figure 3. The frequency shifts of scattered light due to electrophoresis are represented by the slopes of phase plots. The clear slopes of the phase plots display strong signal-to-noise ratios of measurements, as evidenced by these figures.

Figure 1. Size distribution curves of Sample 1# and Sample 2# copolymers. Image Credit: Bettersize Instruments Ltd.

Figure 2. The phase plot and zeta potential trend plot of sample 1#. Image Credit: Bettersize Instruments Ltd.

Figure 3. The phase plot and zeta potential trend plot of sample 2#. Image Credit: Bettersize Instruments Ltd.

Table 1 shows multiple measurement results of two samples, which indicate that the size difference is small. The samples are narrowly distributed in size, which is evidenced by the fact that the PDI of both samples was far less than 0.05.

Regarding zeta potentials, the signs are negative and absolute values are larger than 30 mV. These figures indicate that, in order to keep the latex system stable, a large number of negative charges are carried by the particle surfaces to generate strong electrostatic repulsion.

Table 1. Measurement results of two latex samples. Source: Bettersize Instruments Ltd.

| Sample |

Z-average(nm) |

PD.I |

Zeta potential (mV) |

| 1# |

155.76 |

0.010 |

-52.76±1.31 |

| 2# |

170.31 |

0.002 |

-58.90±1.68 |

Conclusions

The size and zeta potential of the two polystyrene-butadiene copolymer latexes were successfully characterized through the use of the BeNano 90 Zeta. From the result, it is clear that both copolymers are monodisperse in terms of size as well as being less likely to form aggregates due to high zeta potentials.

This information has been sourced, reviewed and adapted from materials provided by Bettersize Instruments Ltd.

For more information on this source, please visit Bettersize Instruments Ltd.