One of the world’s leading producers of plasma and corona surface treatment systems for advanced, front line industries such as aerospace, automotive and medical is using Tinius Olsen equipment.

Manufacturers Tantec UK & Ireland have been performing the treatment system since 1974, which enhanced the surface of materials, particularly non-stick polymers like polypropylene so that during bonding, printing and coating, they retain an adhesive ability.

Revolutionizing the world of surface treatments by fabricating plasma and corona systems for 3D components, Tantec leads the way in the sector, being one of the few organizations specializing in both technologies on a global scale.

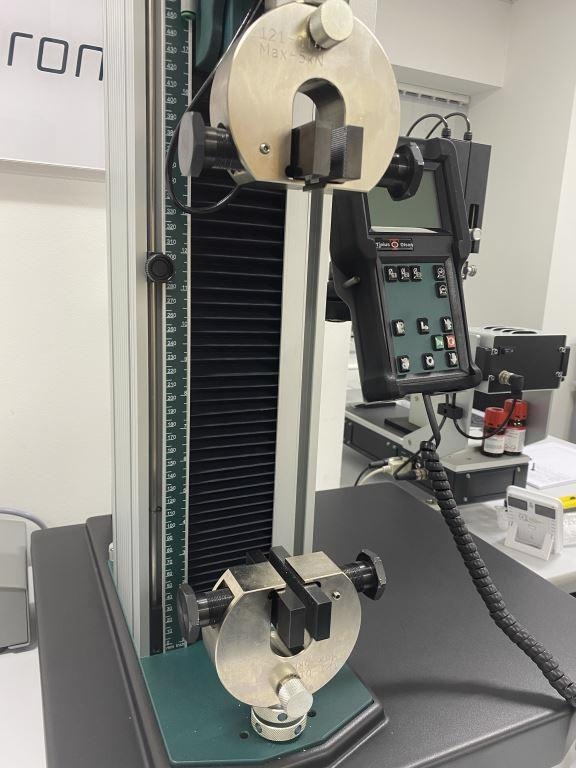

Image Credit: Tinius Olsen

“Each material, adhesive and process is different, or has different performance requirements, so we must test to ensure the process works well for the specific application requirements, which is where Tinius Olsen have become a proven partner,” says Managing Director Chris Howey.

Most of Tantec’s current testing is aimed at project-based applications. This means that Tantec can tailor processes according to the customer’s parameters, materials and adhesives to get actual, real-world results and a formal report.

Image Credit: Tinius Olsen

“Utilizing testing instruments such as a Tinius Olsen 5ST UTM and Horizon testing software, performing lap shear testing gives us firm numbers on the samples and gives impressive results. Lap shear samples are ripped apart, with material failure on the best performing parts. This proof in numbers, and visual display of strength in the part, gave us confidence in taking on a new process and investing in the equipment the company offers,” explains Howey.

Tinius Olsen offered strong support during the specification stage of supplying a system, and helped with installation and further questions. Everyone we dealt with helped in their own way without any frustrations or delays.

Chris Howey, Managing Director, Tinius Olsen

“They have offered support to us for years, working closely with us when we needed them. The price of the equipment was extremely competitive, especially for the quality,” says Howey. One of Tinius’ major advantages is the willingness to approach a client’s needs by discussing the range of testing requirements required: “Speaking with others, we were lead down the route of over-complex machines and systems we wouldn’t use. The Tinius Olsen machine does everything we want and more while still being simple and easy to use,” Howey added.

Image Credit: Tinius Olsen

This information has been sourced, reviewed and adapted from materials provided by Tinius Olsen.

For more information on this source, please visit Tinius Olsen.