It is widely accepted that concrete is the most pervasive and versatile building material on the planet. While the recipe is fundamentally simple — air, water, cement and aggregate — the additions and alternative compositions of the recipe can produce infinite kinds of concrete.

Image Credit: LECO Corporation

Having the knowledge that concrete has the capacity to withstand the forces that will be acting upon it in a given application is key to the success of any construction process using this dynamic material.

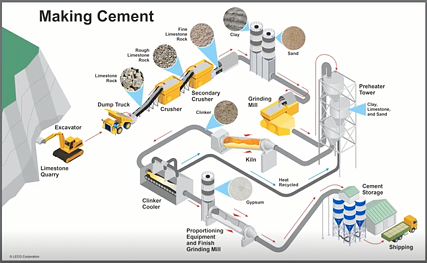

The process of making cement is initiated when limestone is quarried and crushed. Clay and sand are introduced into the mix, which is then ground and processed through a kiln. What is pulled from the kiln is known as ‘clinker,’ which is then cooled, crushed and mixed with gypsum to create the Portland cement that is widely used around the world.

Click here to read 'Metallurgic Analysis of Concrete'

It may seem counter-productive to analyze the clinker – which is an intermediate product in the cement-making process – and not the final Portland cement, but there are a number of valid reasons for doing so.

Image Credit: LECO Corporation

Portland cement powder is extremely fine and much harder to analyze metallographically, whereas clinker is a rock-like, solid material that is well-suited to such analysis. It also enables continuous monitoring of the cement-making process, facilitating real-time adjustments as necessary.

Finally, analysis of the clinker before it is reduced to cement offers a good estimation of the final cement product’s quality. This means that defective batches can be easily rejected rather than being turned into sub-par cement, saving both time and money.

LECO’s Metallurgist, Steve Reilly, goes into fine detail on best practices for conducting a metallographic analysis of cement clinkers in an on-demand webinar.

This information has been sourced, reviewed and adapted from materials provided by LECO Corporation.

For more information on this source, please visit LECO Corporation.