| |

| |

Topics Covered |

| Overview Materials Evolution Wooden and Aluminium Rackets Fibre Reinforced Composites Design Aspects Damping Properties Tennis Elbow “Feel” V Damping Piezoelectrics - The Future? |

Overview |

| Materials technology has played a vital, lately controversial role in the history of the game, especially during the modern era with the advent of powerful composite rackets. However, while the likes of Andre Agassi could beat most of us using a tea tray, for the average player modern rackets offer a range of benefits, such as oversized sweet spots and efficient vibration damping, that make the game hugely more attractive. In fact, new technology could lead to the effective elimination of vibration. |

Materials Evolution Wooden and Aluminium Rackets |

| The very first rackets were made from solid sections of woods such as ash, maple and okume. However, the anisotropic nature of these materials necessitated a change in racket construction to a laminated structure, which allowed the stiffness and strength of the racket to be increased in directions both parallel and perpendicular to its main axis. Although adopting laminates significantly increased racket performance, the problem of water absorption, resulting in pronounced warping in the structure and therefore variable performance, persisted. In the 1970s aluminium frames offering increased stiffness and reduced mass enjoyed a brief period of success. However, towards the end of the decade new continuous fibre composites were introduced that rapidly superseded aluminium as a frame material. The first of these composite materials consisted of glass fibres held within a polyester resin matrix, and later rackets went on to encompass various grades of carbon fibres within epoxy resin matrices. |

Fibre Reinforced Composites |

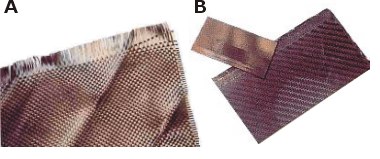

| The short-lived success of aluminium has been attributed to a number of factors. Both glass and carbon fibre composites have a higher specific stiffness (modulus/density) than aluminium, so rackets made from composites can be much lighter, particularly in the case of carbon fibre. Continuous fibres can be woven into a variety of weave styles, giving increased control of the racket's characteristics. For example, unidirectional fibres are incorporated along the main racket axis for high bending stiffness, and 0/90° weaves are stacked at ±45° for high shear strength and stiffness, (figures 1). A variety of fibre grades are used, each with different levels of strength and stiffness. These fibres are coupled with epoxy resin matrices that often contain one or more property modifiers, such as rubber particles and thermoplastics that increase the toughness of the resin. On top of these advantages the fatigue performance of the composite rackets was superior to aluminium constructions. Tests on aluminium rackets have shown that a marked decrease in stiffness occurs at around 6000 impacts, compared with a change in stiffness for carbon fibre rackets of around 4% after 50,000 impacts. Another important factor in aluminium's decline was the comparative damping properties of the frame materials, aluminium has a lower damping capacity than composite materials, and this has implications for the health of players. |

|

|

| Figure 1. (a) A 0/90° impregnated cloth and (b) a unidirectional laminate and a 0/90° twill laminate |

Design Aspects Damping Properties |

| The damping properties of a tennis racket's frame are extremely important. When a ball hits a racket resonant modes are excited within the frame and strings, and these modes are felt by the player as vibration through the handle. The level of vibration perceived by the player depends on several factors. For instance, the modal response of a racket depends on whereabouts on the racket face the impact occurs. There is an area on the strings known as the `sweet spot' in which the modal density is low. A ball striking this area excites few modes and the player perceives little vibration. However, if a ball hits outside this region the resulting frame vibration is significantly increased, and the degree to which these vibrations are transmitted to the handle of the racket is then determined by the damping capacity of the frame materials. |

Tennis Elbow |

| If too much vibration is transmitted from the handle to the hand and arm of the player the painful condition known as lateral epicondylitis, or `tennis elbow' often results. Tennis elbow affects around 45% of people who play regularly and is a particular problem for beginners, who often find striking the ball with the sweet spot more difficult. Hitting with areas other than the sweet spot, where the modal density is higher, has the effect of increasing the amount of vibration transmitted to the hand, which tightens its grip on the racket's handle to compensate and exacerbates the problem. Due to the low damping capacity of aluminium, players using aluminium rackets in the 1970s experienced a high transmission of vibration to their hands and arms, and the number of reported cases of tennis elbow increased. Both glass and carbon fibre composites exhibit higher damping capacities than aluminium and in the case of epoxy resin matrices the rubber toughness modifiers further increase the damping. |

“Feel” V Damping |

| While too much vibration causes tennis elbow, it is important that a player can feel a ball's impact. Complete elimination of vibration would result in a loss of impact information and a corresponding reduction in the player's perception of the impact's characteristics. Damping vibrations may produce a safer racket but may also create a useless one, devoid of any information and `feel: Research in racket design is now attempting to balance the health benefits of damping with the performance of the racket. Various attempts have been made to control the transmitted vibration, ranging from the attachment of string dampers to cushioned grip tape. While studies have shown that the effect of string dampers is negligible, and that using cushioned grip tape can reduce the transmitted vibration by 50%, none of the measurements have taken account of the effect of the hand and arm on the vibrational response and transmission in the racket. The damping capacity of the frame is another key factor. The rebound velocity of the ball can be increased, while the mechanical energy transmitted to the racket and the maximum force transferred to the player can be reduced, all by increasing the damping. However, once again, studies have not accounted for the hand arm system. The impact of a ball on a racket face initiates a sequence of events. The nature of the impact and the material choice of the frame determines the modal response of the racket and the degree of transmission of vibration to the handle. The level of vibration perceived by the player determines the grip force they apply, which in turn determines the level of vibration transmitted to the hand and forearm and the incidence of tennis elbow. |

Piezoelectrics - The Future? |

| The next step in the evolution of the tennis racket may be the inclusion of piezoelectric materials that are capable of controlling the frame vibration. Advances in the technology used in skiing have already led to piezoelectric materials being attached to the surface of skis. At present these materials act in a passive way. The piezoelectric plates have a damping effect by converting the mechanical vibrations into electrical energy that is dissipated through a shunt circuit. A future possibility may be the conversion of the passive configuration to an active form in which the vibrations in the frame are sensed and then cancelled by inverting the electrical signal applied to piezoelectric actuators sited in the handle. It could even be this technology that finally leads to the eradication of tennis elbow. |

| Primary author: Dr. Mike Jenkins Source: Materials World For more information on Materials World please visit The Institute of Materials. |