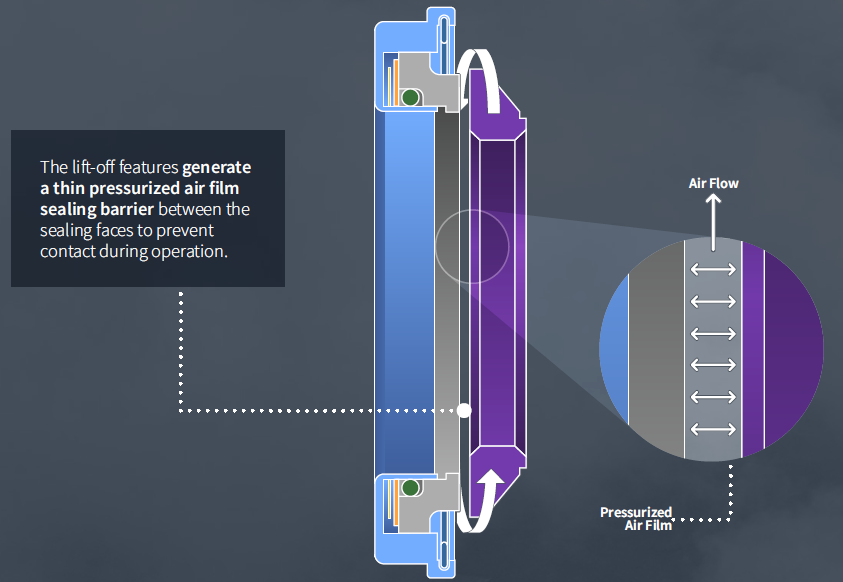

When it comes to high-stake environments, where zero leakage and long service life are a necessity, Qualiseal non-contacting lift-off seals are essential. Qualiseal’s proprietary and proven engineering design incorporates a thin pressurized air film sealing barrier to prevent contact during operation.

Superior film stiffness and film thickness are provided by the advanced spiral lift-off features, which facilitate increased reliability and performance even in high vibration and high altitude applications.

The thin pressurized air film between the sealing faces prevents contact during operation, while the solution operates with minimal heat generation, low wear, and a virtually leak-free process.

As the solution is non-contacting, a negligible wear rate, a longer seal life and a lower operating temperature are ensured, allowing users to fulfill the metrics they need whilst protecting the elements that matter.

Image Credit: Technetics Group

Features and Benefits

Image Credit: Technetics Group

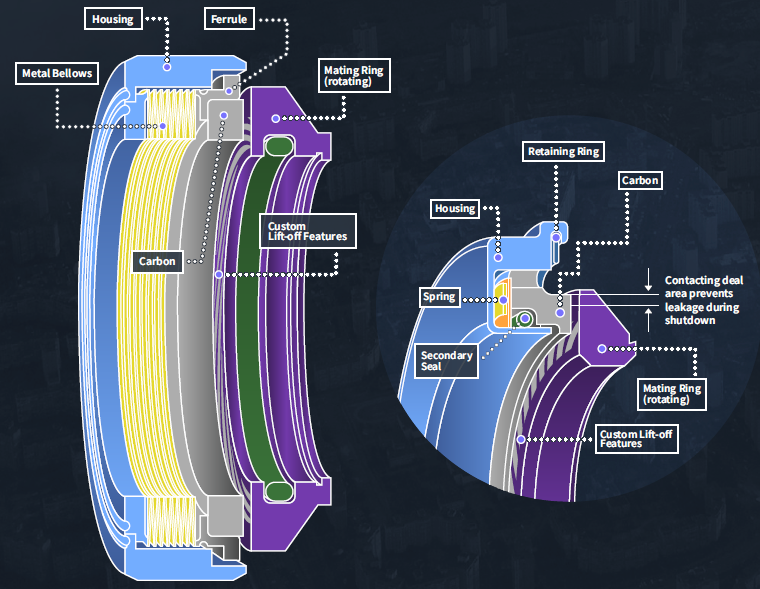

There are a huge range of features and benefits to the Qualiseal non-contacting lift-off seals. These features include a set of custom-designed advanced spiral features for high altitude and high-vibration environments and metal bellows or spring energized with a secondary seal design.

The benefits of the Qualiseal non-contacting lift-off seals include the negligible wear compared to the contacting seal; the fact that the robust design does not need special materials or coatings; a direct replacement for the contacting face seals within the existing envelope; and, of course, a superior service life.

The Qualiseal non-contacting lift-off seal also offers virtually zero leakage and significantly lower heat generation than contacting face seals.

To find out more about the Qualiseal non-contacting lift-off seal range of products, visit technetics.com today.

This information has been sourced, reviewed, and adapted from materials provided by Technetics Group.

For more information on this source, please visit Technetics Group.