This interview with Francis Quintal Lauzon, Director of Product and Innovation at Clemex Technologies, discusses using artificial intelligence in image analysis. He discusses the challenges involved with automation in microscopy, as well as possibilities for the future of AI.

Artificial intelligence, deep learning, machine learning, neural networks - Can you give an overview of how these are employed within the Clemex approach?

Traditionally, proposing automation of image analysis for microscopy is a complex thing. We at Clemex offer user training and method development through professional services. So AI brings a new era of simplicity to Clemex products. With AI, we essentially allow users with very simple gestures and learning to be able to automate their own methods. This grants the user more productivity, more possibilities, and reduces cost.

Image Credit: Clemex

What are some of the challenges that push customers towards using AI in your image analysis systems?

There are many challenges with automation in microscopy. One of those challenges is the cost and complexity of automating your own method. That is one challenge that is overcome with AI, where we increase the simplicity and speed of developing your own method.

A second challenge is training people to use a complex, automated image analysis system. Then again, we chose the route of simplicity with our system where people will be able to learn very simply how to use our software. Another challenge with image analysis is reproducibility, especially with manual methods, either a threshold or making your own measurements on the image. What we propose with AI is something that is more reproducible through robustness to different operating conditions.

Are there any advantages to the fact that you are based in Montreal?

Historically, the University of Montreal has been one of the pioneers in deep learning research. For example, generative adversarial networks were developed in Montreal. Today, Montreal still attracts top talents, and we have a premium software and machine learning ecosystem.

Image Credit: Clemex

Which part of the analysis is actually improved by AI?

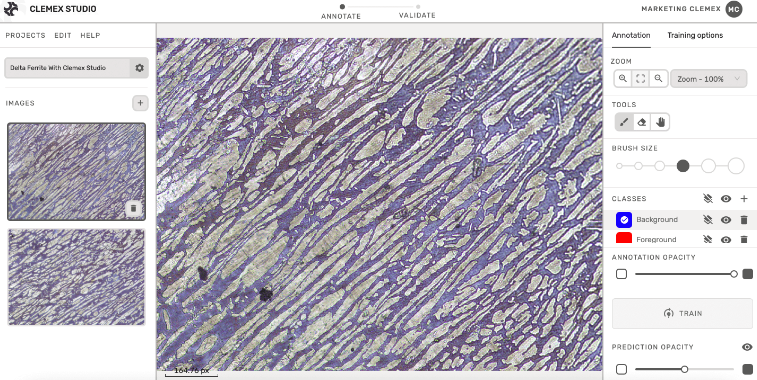

Our primary focus when it comes to improving the microscopy workflow is associated with image segmentation. Some people often call this object detection or simply detection. Image segmentation in the context of what we are talking about is essentially assigning a label to each pixel. So for instance, if you are going to do delta ferrite, you will label each pixel as either delta or ferrite. In the future, there are other components of computational microscopy for automation that can also be automated to simplify the microscopic workflow, and we will definitely work on those as well.

Tell us about the new platform, Clemex Studio?

So Clemex Studio is a new web platform that we are developing here at Clemex. And this platform is basically enabling a user to detect some property in an image. In order to do so, the user simply has to colorize on top of the image where this property is located. And this action is basically telling the computer how and what those properties look like, enabling it to learn from that.

This is a big difference from traditional thresholding algorithm, and this is what we call threshold-less image segmentation. Clemex Studio is also used inside an ecosystem here at Clemex. And this ecosystem is in part with Vision PE and under software that we are developing here that can produce measurements from the segmentation created within Clemex Studio on never-seen-before images.

Image Credit: Clemex

What type of user is Clemex Vision PE designed for?

Clemex Vision is a computational microscopy software that is designed for operator, technician and engineer level staff with domain knowledge but without extensive computer vision experience. Operators can run automated analysis methods in batch very simply. Technician and engineers can create their own automated image analysis methods and apply those in batch for production.

Which applications or industries is the system best suited for?

Clemex Vision can be applied to any image analysis problem in any industry. In practice, most of our customer base are metallographic labs, in all industries where such labs exist such as aerospace, automotive, foundries, metal casters, pharma and more recently additive manufacturing etc. Applications of our software range from powder characterization, metallographic analysis, to filter cleanliness analysis.

In your opinion, why is the boom in AI happening right now in your field?

There is an obvious change in culture. People are more and more comfortable with artificial intelligence. People understand this a little bit more, and there is also obvious, tangible business value to it. Everybody knows about the industry 4.0 trend where there is a strong push towards valorization of data and automation. Companies are looking for more value and more productivity from people. The pandemic also accelerated this whole movement.

Image Credit: Clemex

Do you foresee more possibilities in the future?

Absolutely. I think methods development can be even more simple with new AI methods. Image acquisition, capturing your image from the microscope, can also be made simple and robust. Finally, this idea of the system learning from the user through continuous learning may also be a possibility in the future.

About Francis Quintal Lauzon

Francis Quintal Lauzon has held several positions at Clemex Technologies since 2012. First, as a computer vision development specialist, then Director of Machine Learning, Chief Technology Officer and now Director of Products and Innovation.

Francis Quintal Lauzon has held several positions at Clemex Technologies since 2012. First, as a computer vision development specialist, then Director of Machine Learning, Chief Technology Officer and now Director of Products and Innovation.

Prior to his employment at Clemex, Francis worked at Zygo Vision Systems, a Canadian subsidiary of Zygo Systems now part of Ametek, focusing on automated optical inspection of semiconductor components.

Francis graduated in Engineering Physics from Polytechnique Montreal in 2005. He has a passion for simplifying deep learning and computer vision, making such tools easily accessible to non-specialists.

Francis represents Clemex in the METALTec Industrial R&D group of the National Research Council of Canada. METALTec’s objective is to build a research community that catalyzes innovation in the metal fabrication sector in the digital era.

This information has been sourced, reviewed and adapted from materials provided by Clemex Technologies.

For more information on this source, please visit Clemex Technologies.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.