Polyethylene (PE) is widely used in different fields and for various industrial and domestic purposes. Analysis of polyethylene materials is vital to ensure the presence and suitability of these properties to effectively fulfill the objectives of material applications.

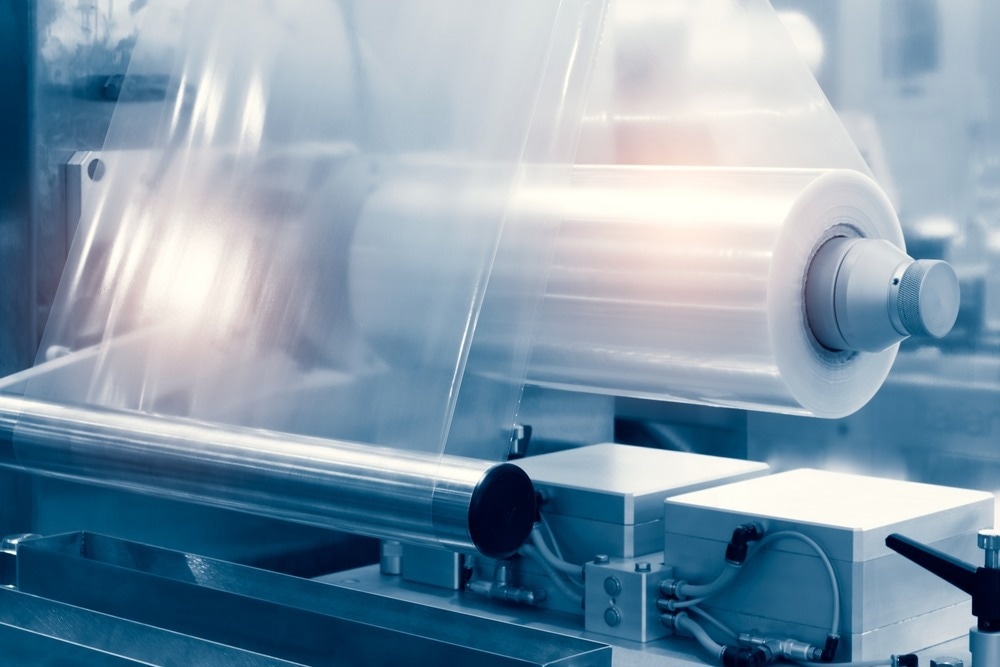

Image Credit: Eliz A/Shutterstock.com

Owing to the importance and widespread applications of polyethylene materials, sophisticated analytical techniques have been developed in recent years to help study and improve their characteristics. When analyzing polyethylene, the parameters usually depend on the particular application for which the material is to be used. However, the density and isomerism of the polymer carbon chains are always a subject of analysis.

Applications of Polyethylene

The primary and most comprehensive application of polyethylene is as a packaging material. The United States Environmental Protection Agency (US EPA) reports that an estimated 100 million plastic packaging materials made of polyethylene are produced globally every year.

In addition, polyethylene is also heavily produced and used for making fishing and sporting nets, electrical wire and electronics casing, home utensils such as jugs and plates, and the production of ropes. Owing to the insulating properties of polyethylene, it is extensively used in automobile and electrical fields. In medical practice, polyethylene is also used in some surgical processes, especially in the stitching of wounds and cuts.

Properties of Polyethylene

The physical and chemical properties of polyethylene form the basis for its analysis. The basic properties of polyethylene include:

Low mechanical strength: This gives polyethylene a unique light weight and makes it suitable for use as a packaging material.

High ductility: Polyethylene is very ductile and can be beaten into any shape at high temperatures.

Waxy Nature: This makes it very suitable as a liquid and air-proof material for packaging sensitive products.

Conductivity: Polyethylene is a pure insulator. This makes it suitable for use in casing conductive materials and packaging.

Resistance to chemical degradation: Polyethylene is relatively resistant to chemical attacks, making it suitable as a packaging material.

Crystalline Nature: Polyethylene has a semi-crystalline nature. Low-density polyethylene is about 35% crystalline, while high-density polyethylene is about 80% crystalline.

Types of Polyethylene

Polyethylene is classified based on two broad characteristics: density and isomerism (type of branching present). The categorizations include:

- High Modulus Polyethylene

- Ultra-low-Molecular-Weight Polyethylene

- High-Density Cross-Linked Polyethylene

- High-Density Polyethylene

- High-Molecular Weight Polyethylene

- Cross-Linked Polyethylene

- Medium-Density Polyethylene

- Low-Density Polyethylene

- Linear Low-Density Polyethylene

- Chlorinated Polyethylene

Chemical Composition of Polyethylene

Polyethylene is a product of a polymerization reaction where multiple ethylene (C2H4) monomers undergo condensation polymerization in the presence of a catalyst to build a polymer of ethylene compounds known as polyethylene. This reaction is highly exothermic.

In branching polyethylenes, the double bond in CH2 = CH2 can be broken with the help of a catalyst to create a link-up for another carbon-hydrogen bond, thereby creating a sizeable polymeric molecule of ethylene. Cross-linked polyethylene, usually referred to as PEX or XPE, is a special type of polyethylenes with relatively high density and mechanical strength. It is generally used in the construction of pipe-work systems and ventilating technology.

Analysis of Polyethylene (PE)

Current procedures in elucidating polyethylene's structural and chemical properties represent a complex challenge in its subsequent applications. Thermal analysis is a popular and widely researched technique for characterizing PE. A popular property that affects the choice of method is the density which invariably affects the melting behavior. The next section reviews some of these methods to discuss current trends in PE analysis.

Image Credit: Matveev Aleksandr/Shutterstock.com

In a study published in the Journal of the American Society for Mass Spectrometry, the characterization of branching by thermal analysis-photoionization mass spectrometry showed excellent efficiency of the thermo-related analytical techniques in studying the properties of polyethylene materials. This analysis studied the effects and methods of improving branching in polyethylene materials.

In this study, the authors applied thermal analysis coupled to a single photon ionization mass spectrometry (STA-SPI-MS). The melting and pyrolysis point of the polyethylene samples were observed using DSC and mass loss. This is based on the fact that crystallinity and melting point information hint at the branching in polyethylene. The evolving gas was analyzed using SPI-MS to obtain specific molecular weight information from the samples. Chemical shifts in the summed spectra were also used to show spectral patterns, confirming the diversity of the structure of the different polyethylene materials analyzed. Principle component analysis was also applied to reveal the molecular fingerprints of the different samples.

In another study published in the Asian Journal of Chemistry, the authors reported a qualitative analysis of high-density polyethylene using Fourier Transform Infra-Red Spectroscopy (FTIR spectroscopy). This technique was used to complete a qualitative analysis of the high-density polyethylene polymers. The FTIR was used to analyze the molecular structures of the repeating unit of the standard HDPE samples. The standard samples were computed for specified modes of vibration in the FTIR. The same method was applied to the HDPE samples under study, and the similarities and differences were evaluated to determine the molecular structure of the polyethylene. This method is very reliable for measuring the purity of high-density polyethylene samples.

The use of thermal methods in polyethylene analysis is a robust one. The methods use highly selective techniques to achieve a reasonable degree of accuracy in elucidating the properties of polyethylene materials. These tests can give a manufacturer a good knowledge of manipulating polyethylene materials to achieve production objectives.

More from AZoM: An Overview of Polymer Upcycling

References and Further Reading

Mclain V. C. (2007). Final Report on the Safety Assessment of Polyethylene, A case Study by the United States Environmental Protection Agency. International Journal of Toxicology, Vol. 26, pp: 1091 – 5818.https://hero.epa.gov/hero/index.cfm/reference/details/reference_id/1093504

Rego A., Silva A. S., Grillo A. V., Santos B. F. (2019). Thermogravimetric Study of Raw and Recycled Polyethylene Using Genetic Algorithm for Kinetic Parameters Estimation. Journal of Chemical Engineering Transactions. Vol. 74.https://pubs.acs.org/doi/10.1021/jasms.0c00291

Charles J., Ramkumaar G. R. (2009). Qualitative Analysis of High-Density Polyethylene Using FTIR Spectroscopy. Asian Journal of Chemistry, Vol. 21, No. 6, pp: 4477 – 4484. https://asianjournalofchemistry.co.in/User/ViewFreeArticle.aspx?ArticleID=21_6_52

Sze H. C. (1986). An Overview of Thermal Analysis of Polymers. Asian Journal of Science and Technology for Development, Vol. 3, No. 1, pp:36 – 54. https://www.researchgate.net/publication/322079857_An_Overview_of_Thermal_Analysis_of_Polymers

Grimmer C., Friederici L., Thorsten S., Naim A., Cirriez V., Giusti P., Alfonso C., Ruger C. P., Zimmermann R. (2020). Characterization of Polyethylene Branching by Thermal Analysis-Photoionization Mass Spectrometry. Journal of the American Society for Mass Spectrometry, Vol. 31, No. 11, pp: 2362 – 2369 https://pubs.acs.org/doi/10.1021/jasms.0c00291

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.