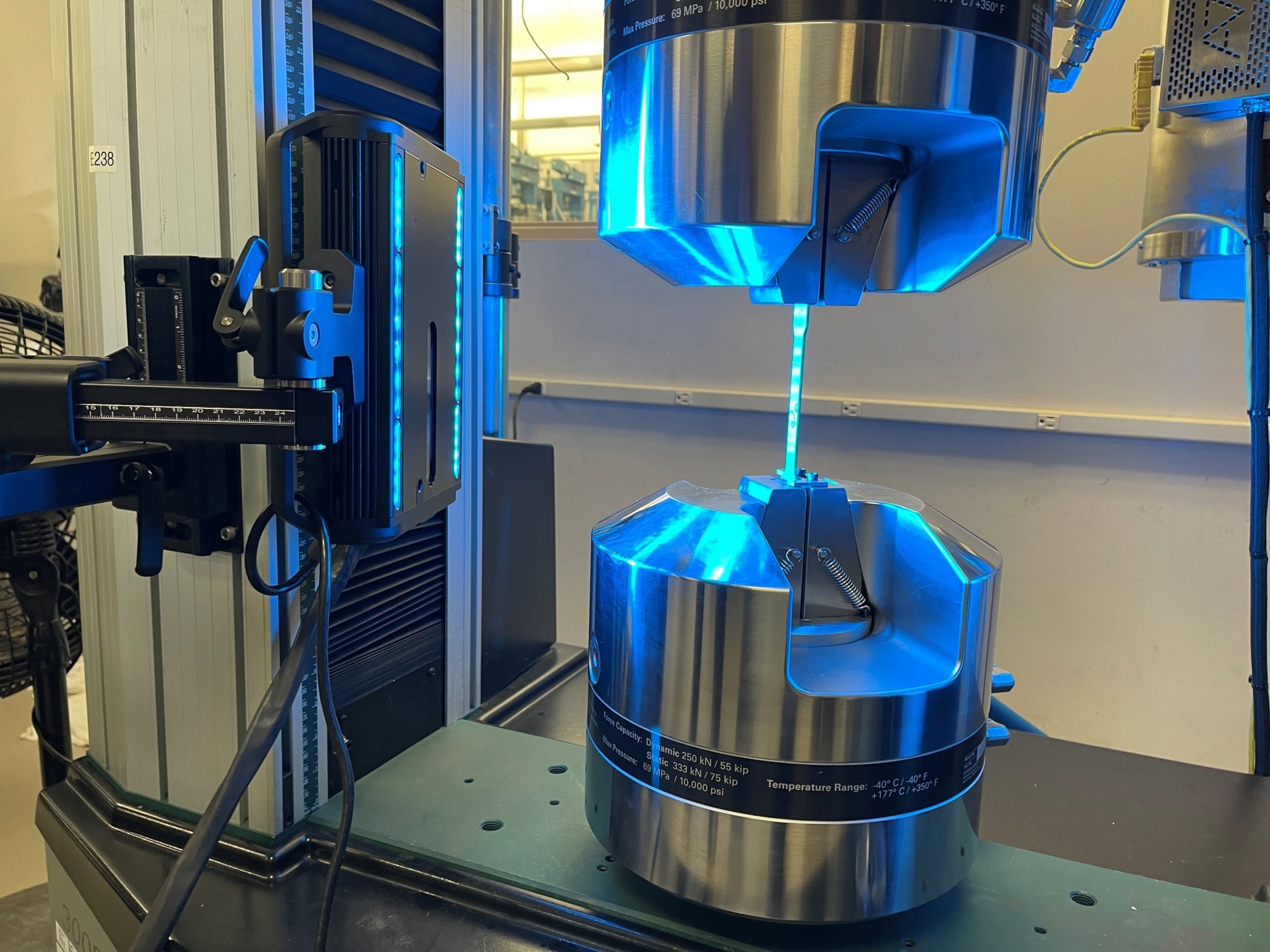

The new VectorExtensometer from Tinius Olsens represents a true advancement in extensometer technology. It enables several contacting and non-contacting sensors to be replaced with a single, customized instrument.

Image Credit: Tinius Olsen

Vector decreases test throughput times and intricacy by combining adaptive AI capabilities with optical hardware, automating the strain-capture process, and enhancing measurement accuracy, data consistency, and operator safety.

The limitations of conventional contacting and non-contacting extensometers are eliminated by this ground-breaking technology, which uses sophisticated non-contact, high-accuracy measuring techniques to:

- Simultaneously measure longitudinally and transverse

- Increase testing efficiency by reducing the need for operator intervention

- Eliminate the cost of consumable parts

- Measure strain through failure, however violent

- Test in harsh environments or challenging light conditions

- Avoid introducing stress concentrations, such as damage from knife-edge contact

- Improve test success rate by eliminating contact-point slippage

- Test highly fragile specimens

- Locate below the moving member used to apply the test force viewing the test specimen across the test zone on larger test frames

Simple, Reliable Operation

Plug in, turn on, and start using Vector after it has been delivered pre-configured.

While a variety of automation features, such as specimen and gauge length detection, enable easy operator involvement and boost test reliability, both instrument setup and changes to accommodate varying gauge lengths, sizes and profile test specimens are eliminated.

VectorExtensometer : The Future Of Extensometry

Video Credit: Tinius Olsen

The onboard processing provides seamless and simple integration while removing all external control platforms. Its stereoscopic sensing identifies machine or specimen misalignment and eliminates out-of-plane errors.

Laser alignment guides and easy visual status reporting vastly enhance test throughput while requiring less operator training.

Advanced Functionality

In addition to accelerating and streamlining test execution by automating specimen detection, Vector eliminates the requirement for several conventional sensors by enabling different gauge lengths.

Vector can be used on practically any test frame due to its generous operating envelope and big working optical volume.

With a dynamic response to varying specimen appearance and behavior and smooth changeover between test and validation mode, onboard AI provides completely zero-touch operation.

There is no need to modify the setup for specimens of various sizes, shapes, and thicknesses due to Vector’s clever design.

The user experience is made simpler and the requirement for an external interface is eliminated by full integration with UTM control software.

This information has been sourced, reviewed and adapted from materials provided by Tinius Olsen.

For more information on this source, please visit Tinius Olsen.