Selected ion flow tube mass spectrometry (SIFT-MS) is a form of direct injection mass spectrometry that analyzes volatile organic compounds (VOCs) in real-time that are present in air with standard limits of detection in the region of parts-per-trillion (by volume; pptV).

Through the application of precision-based soft chemical ionization, quantitative analysis can be run in real time, eliminating the need for sample preparation, pre-concentration, and chromatography.

Benefits of SIFT-MS

- Instantaneous, quantitive analysis of air and headspace with very high sensitivity and selectivity

- Simplicity of operation

- Direct analysis of high-humidity samples

- Simultaneous analysis of chemically diverse VOCs (e.g. aldehydes, amines, and organosulfurs)

- Simple integration with existing infrastructure

- Long-maintenance and long-term stability

Image Credit: Syft Technologies

SIFT-MS is considered the perfect tool for achieving high-throughput and real-time gas analysis in various applications. Syft’s SIFT-MS offers all users, regardless of skill level, access to laboratory-quality chemical analysis in an easy-to-read format which means actions and decisions can be taken more quickly.

An Overview of SIFT-MS

As a form of direct mass spectrometry, SIFT-MS uses precision-controlled chemical ionization reactions to detect and quantify trace amounts of VOCs and inorganic gases.

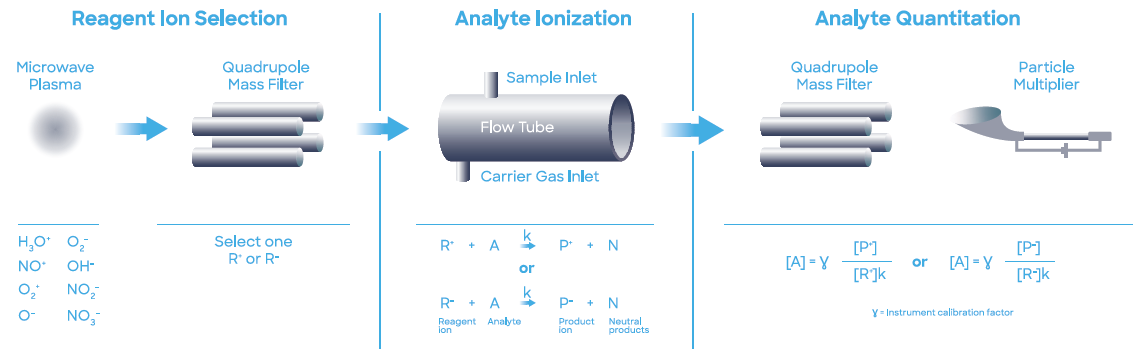

There are three main components to the SIFT-MS method:

- Eight SIFT-MS reagent ions (H3O+, NO+, O2, O-, O2-, OH-, NO2-, and NO3-) are all generated via microwave discharge through dry or moist air. The appropriate reagent ion is then selected using a quadrupole mass filter.

- The reagent selected for use is injected into the flow tube, and any excess energy is removed through a series of collisions with a carrier gas. The sample is then introduced at a known flow rate, and the reactive compounds therein are subjected to ionization by the reagent ion to produce well-characterized product ions.

- Product ions and unreacted reagent ions are sampled into a second quadrupole mass spectrometer. Using Syft’s compound library, the software is able to calculate the absolute concentration of each analyte instantaneously.

Figure 1. Schematic representation of the SIFT-MS technique. Image Credit: Syft Technologies

Principles of SIFT-MS

Soft chemical ionization is performed with closely guarded precision in SIFT-MS, which offers unrivaled selectivity when compared to other mass spectrometry methodologies.

Why Chemical Ionization?

Chemical ionization (CI) takes a molecular ion and transfers charge onto a target compound (analyte). CI ionization is considered a ‘soft’ type of ionization in contrast to other methods owing to a decrease in fragmentation as less energy is transferred to the target analyte.

SIFT-MS stands unique in this regard as it closely controls the energies of reagent ions to facilitate repeatable quantitative analysis in real-time. Another significant advantage of this technique is long-term calibration stability.

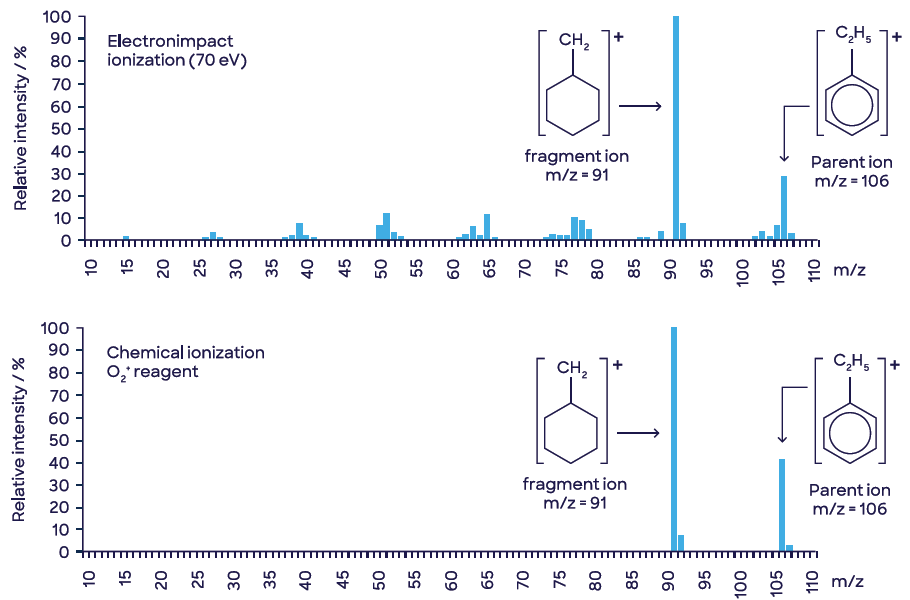

Figure 2 compares the ionization of ethylbenzene using 70-eV El (as typically used in GC/MS) and O2+Cl (used in SIFT-MS). Due to the reduced fragmentation, chromatography is unnecessary, facilitating the real-time application of SIFT-MS.

Figure 2. Electron impact and chemical ionization of ethylbenzene illustrates the much simpler fragmentation observed for SIFT-MS than standard GC/MS. Image Credit: Syft Technologies

Why Multiple Reagent Ions?

With SIFT-MS, eight reagent ions (H3O+, NO+, O2, O-, O2-, OH-, NO2-, and NO3-) can be used as they improve the specificity of the method and enable the detection of an extensive range of different compounds. These reagent ions offer a variety of reaction mechanisms, meaning they demonstrate a different reaction with a particular compound.

The dominant mechanisms are shown below:

- H3O+ = Proton Transfer

- NO+ = electron transfer (ET), association, hydride (H-) extraction

- O2 = ET, dissociative ET, hydride (H-) abstraction

- O- = ET, proton abstraction (PAb), association, displacement

- O2- = dissociative ET, PAb, association

- OH- = ET, PAb, displacement, elimination

- NO2- = ET, dissociative ET, PAb, association

- NO3- = PAb, association

Various reaction mechanisms produce different “fingerprints” for the sample analytes, which are typically different for each individual reagent ion.

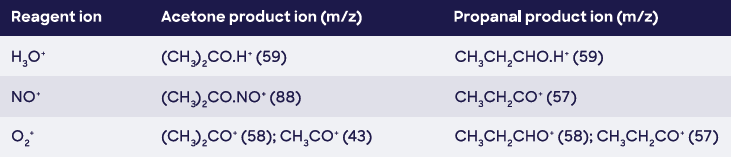

Table 1. Product ions formed from reaction of the SIFT-MS H3O+, NO+ and O2+ reagent ions with isomeric compounds acetone and propanal. Source: Syft Technologies

How Does SIFT-MS Achieve High Measurement Precision?

To control analyte ionization in a suitable manner, maintaining consistency in the energy of the reagents is crucial. This then allows for the generation of reproducible product ion formation and delivers stability in absolute quantitation.

SIFT-MS uses the carrier gas to control the CI process in an improved manner when compared to EI ionization and other CI mass spectrometry methods, including APCI-MS, DART, and PTR-MS.

The carrier gas employed in SIFT-MS has two distinct key roles:

- Thermalization of the reagent ions before the sample is introduced. This maintains low, uniform energy levels in the reagent ions, which allows for precise and ultra-soft CI.

- The carrier gas transports product and unreacted reagent ions through the flow tube without generating excess energy. For instance, no electric field gradient is required to accelerate the ions toward the detection region. Low energy transport effectively minimizes fragmentation while optimizing spectral simplicity, selectivity, and the capacity to identify and quantify compounds.

How Does SIFT-MS Instrumentation Deliver Real-Time Absolute Quantitation?

Selected ion mode (SIM) analyses in SIFT-MS are parallel to GC/MS SIM analyses and necessitate the targeting of known compounds. When using this mode, specific reagents and product ions are chosen and subjected to repeated measurement of their count rates.

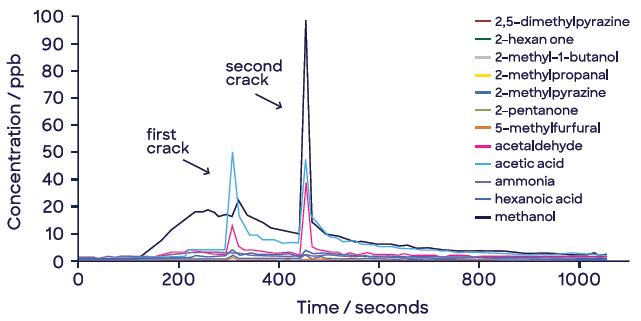

Combining the experimental data with the known rate coefficient (k) of the reagent ion and analyte’s respective reaction from Syft’s library and the known dilution of the sample gas into the carrier gas facilitates the real-time absolute quantitation of an analyte's concentration (Figure 3.).

To put it in simple terms, the greater the concentration of a compound in the sample, the greater the reaction of the reagent ion, meaning an increase in the number of product ions observed.

The number of product ions is an absolute measure of the compound concentration in the sample. This provides a linear range from low-pptV to around 50 ppmV – more than six orders of magnitude. Samples with higher concentrations are analyzed by either attenuating the sample flow or by diluting.

Moreover, SIFT-MS possesses a wide dynamic range: it is possible to detect compounds at pptV levels in the presence of compounds at mid- to high-ppm concentrations.

Figure 3. Real-time quantitation of VOCs produced during coffee bean roasting. Beans ‘crack’ during roasting, releasing additional VOCs. Image Credit: Syft Technologies

Calibration of SIFT-MS Instrumentation

SIFT-MS facilitates precise, absolute quantitation of target compounds predicated on the compound data held in the Syft library (specifically the coefficient of the reaction rate and the product masses along with their branching ratios).

It is also possible to perform the formal calibration in a standard manner to offer greater accuracy. Once the SIFT-MS has been calibrated for a specific compound, it remains valid for a prolonged period of time when daily automation performance checks are performed.

Certified gas standards are employed for the calibration of SIFT-MS instruments. Compressed gases and permeation tubes are the two most predominant commercial options for acceptable standards.

Operational Advantages of SIFT-MS

Syft technologies has been able to develop commercial instruments with exceptional usability and integration advantages owing to the inherent characteristics of SIFT-MS, such as precision ionization control and the absence of a chromatographic column. These characteristics offer significant advantages over other chromatographic and mass spectrometric methods.

Ease-of-Use

Syft’s software was developed to complement the performance of the powerful SIFT-MS technology and provide laboratory quality analyses for all types of users regardless of experience. Features included in the software are as follows:

- Alerts when a specific compound exceeds a user-defined threshold or if patterns and trends show processes are drifting beyond specification

- Customizable compound lists

- Intuitive touchscreen technology and menu-driven analysis

- Instantaneous reports of quantitative results are reported when the analysis is complete

- Simplified workflow screens for simple operation

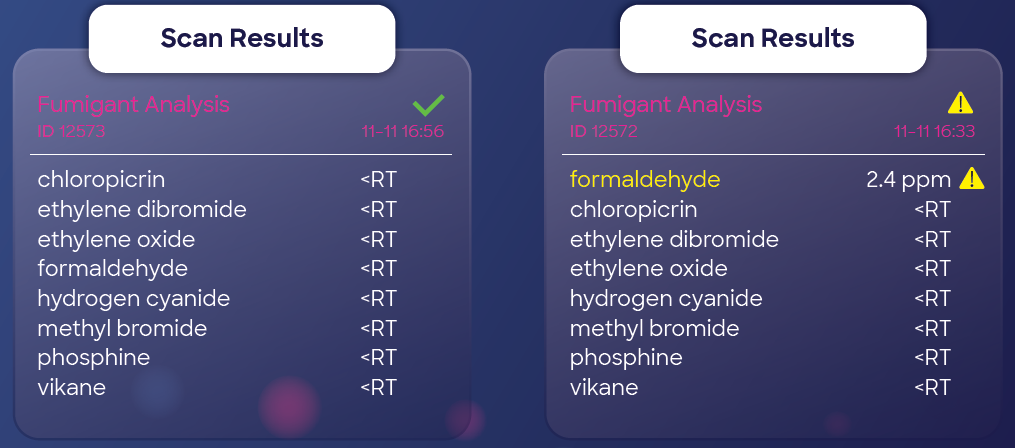

Figure 4 highlights how a laboratory-grade analysis has been configured for easy operation for non-technical users.

Syft also offers LabSyft, a suite of analytical tools that allow advanced and experienced users to access data during and after scans as well as enabling a whole host of other possibilities, including being able to manipulate and export data, search and expand the compound library, create and edit analytical methods, execute batch sequences, and connect the instrument with other devices.

Figure 4. The Voice-series software is readily configured for use and interpretation by non-technical operators. These screenshots from the Voice200 instrument’s touchscreen show two results screens from a worker safety application. RT is a reporting threshold that the employer has chosen, below which the results are hidden from the operator to avoid causing unnecessary alarm. One screen shows a pass result with acceptable levels of target compounds, while the other shows unacceptable formaldehyde levels. Image Credit: Syft Technologies

Remote Operation

Syft Voice-series SIFT-MS instruments can be connected to a network, making operation, data handling, and troubleshooting remotely possible from any location in the world via smartphones or tablets.

This facilitates automated scanning and leading-level support, and fault diagnostics to any location in any time zone.

Low Maintenance

Routine maintenance of SIFT-MS systems is minimized and streamlined due to the absence of chromatographic columns and gas-only analysis.

The main benefit of using clean, stable chemical ionization is that SIFT-MS maintains prolonged calibration stability backed up by the day-to-day use of automated performance checks.

The stability of the instrument’s response throughout the entire mass range is confirmed by the analysis of multiple component certified gas standards – the so-called Syft Calibrant Standard – using automated performance checks.

Technical Support

Syft and its partner distributors provide a range of comprehensive maintenance and support services for the Voice-series instruments and complementary accessories and applications.

The remote access feature of the instruments facilitates support and monitoring anywhere in the world where access to the internet is available. Remote diagnosis, in combination with the modular design, enables the identification of any faults and minimizes downtime as parts can be quickly replaced.

Summary

SIFT-MS provides access to real-time, non-discriminatory analysis of VOCs and inorganic gases in whole air with high sensitivities in an easy-to-use package.

The increase in stability and reduced maintenance is facilitated by the absence of chromatography columns and extremely clean, precise chemical ionization. Compared to other mass spectrometry techniques, SIFT-MS is the ideal analytical tool for both the laboratory and industry.

This information has been sourced, reviewed and adapted from materials provided by Syft Technologies.

For more information on this source, please visit Syft Technologies.