Sponsored by TOFWERKReviewed by Emily MageeDec 8 2022

Sensitive and quick detection of airborne molecular contaminants (AMCs) in semiconductor fabrication facilities is crucial to the quality and efficiency of production. Fabs have the potential to host hundreds of independent processes that act as contamination sources, such as leaks, ventilation systems, device failures, and human emissions.

Image Credit: TOFWERK

AMCs comprise a range of chemical compound classes that are not extensively quantified by traditional monitoring methods. Since nodes continue to progress to smaller dimensions, the existence of AMCs at trace concentrations (<10 ppt) has a greater impact on wafer defects, leading to yield loss.

A considerable variation in physicochemical properties is found in AMC classes, uniquely reacting or interacting with surfaces or other compounds.

As a result of AMC composition complexity, modern monitoring systems should extensively quantify a broad range of compounds covering several chemical functionalities and a range of vapor pressures with adequate sensitivity and speed.

Using real-time chemical ionization time-of-flight mass spectrometry integrated with proprietary quick polarity and reagent ion switching, ClearFab ABC tracks assistance up to six chemical ionization chemistries.

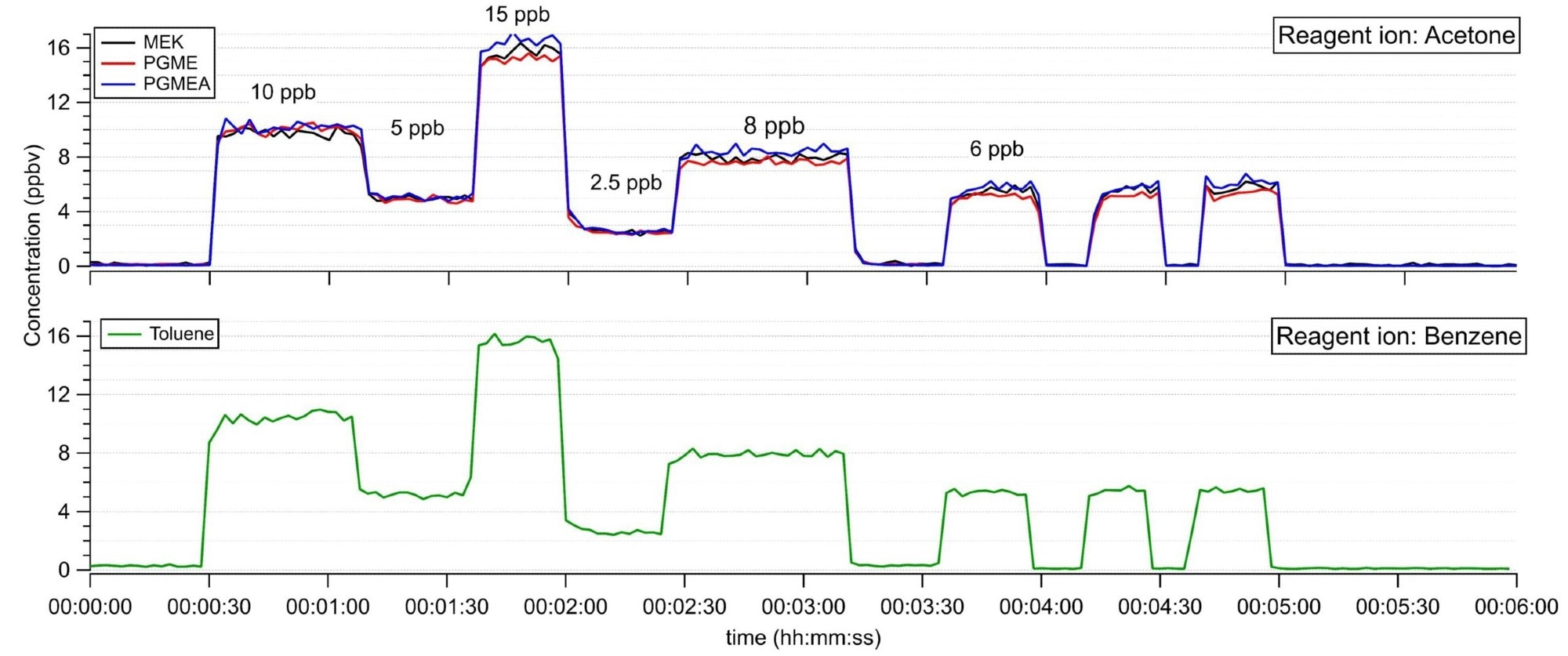

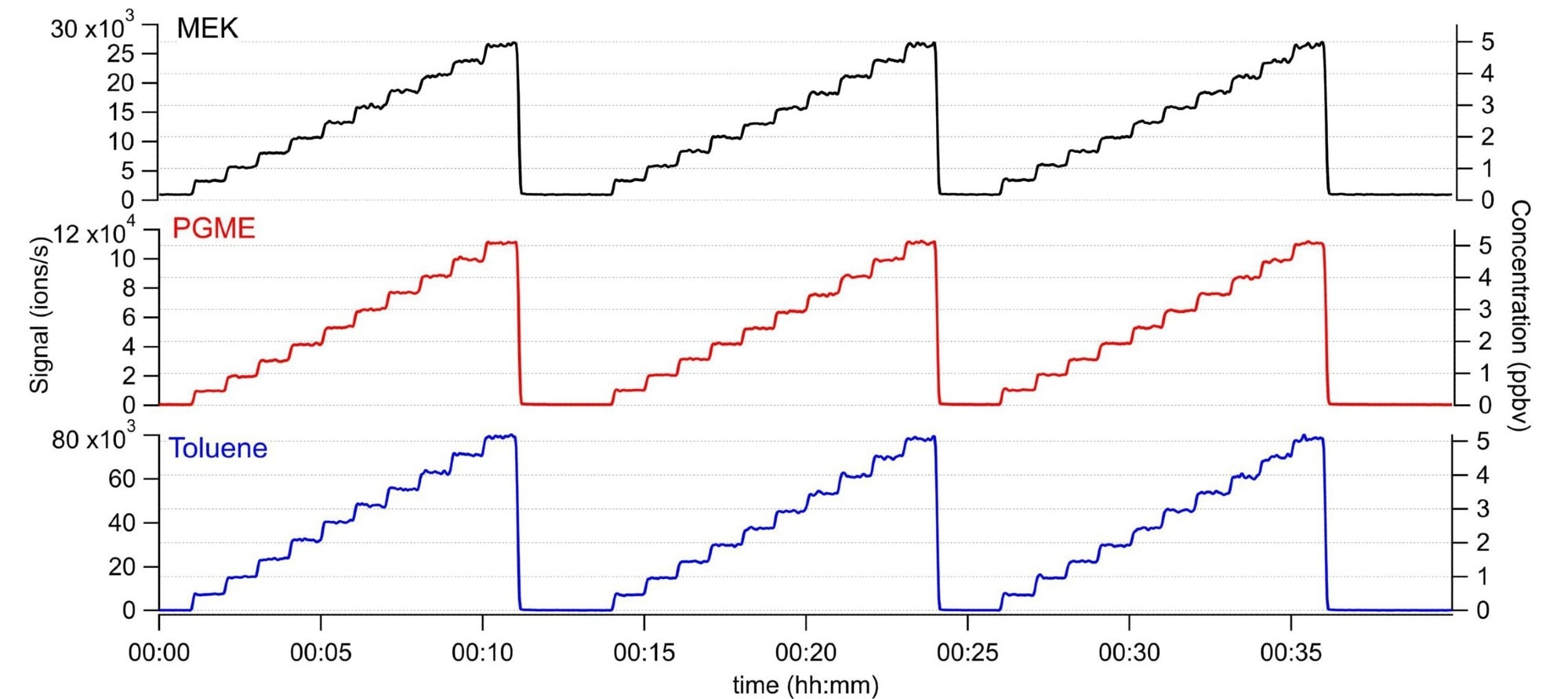

This enables the detection of multiple AMC classes with a cycle time below two seconds. Figure 1 illustrates the ABC monitoring configuration’s recovery and response time.

Figure 1. Response and recovery time of a ClearFab AMC Monitor. Labels in the plot show target concentrations while the Y-axis shows the measured concentration of selected compounds. The upper plot shows the concentration of MEK, PGME, and PGMEA measured with one chemical ionization chemistry, while the lower plot shows the simultaneous measurement of toluene with another chemical ionization channel chemistry. Image Credit: TOFWERK

Utilizing soft ionization, AMC constituents are quantified with insignificant fragmentation, allowing strong data quantification and direct mass spectra interpretation.

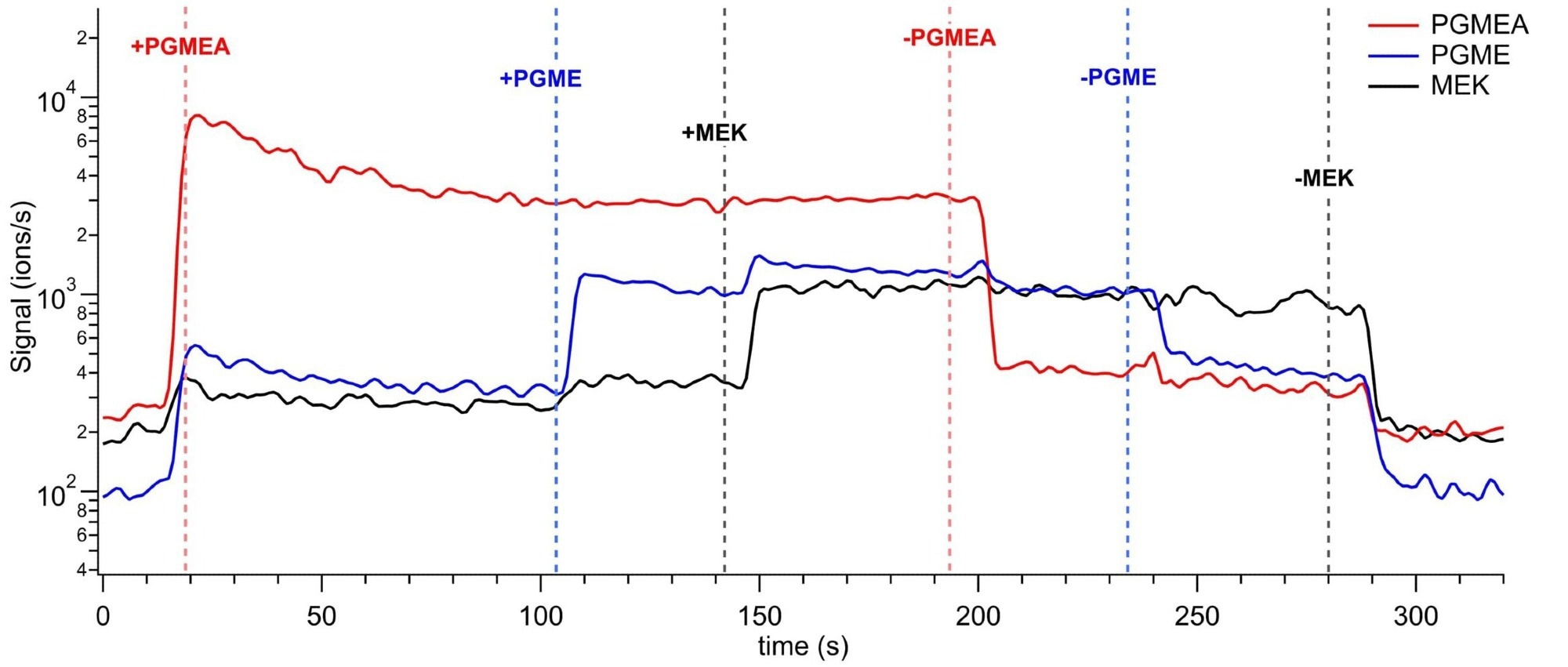

As a result of the fragmentation, compounds such as propylene glycol methyl ether (PGME, 107-98-2), propylene glycol methyl ether acetate (PGMEA, 108-65-6), and methyl ethyl ketone (MEK, 78-93-3) are difficult to differentiate with traditional AMC monitors.

Figure 2 presents the sequential measurement and elimination of such compounds to illustrate the efficacy of the fragmentation-free detection offered by the soft ionization of the monitor.

Figure 2. Sequential measurement and removal of PGMEA, PGME, and MEK demonstrating the detection of these challenging compounds without fragmentation. Image Credit: TOFWERK

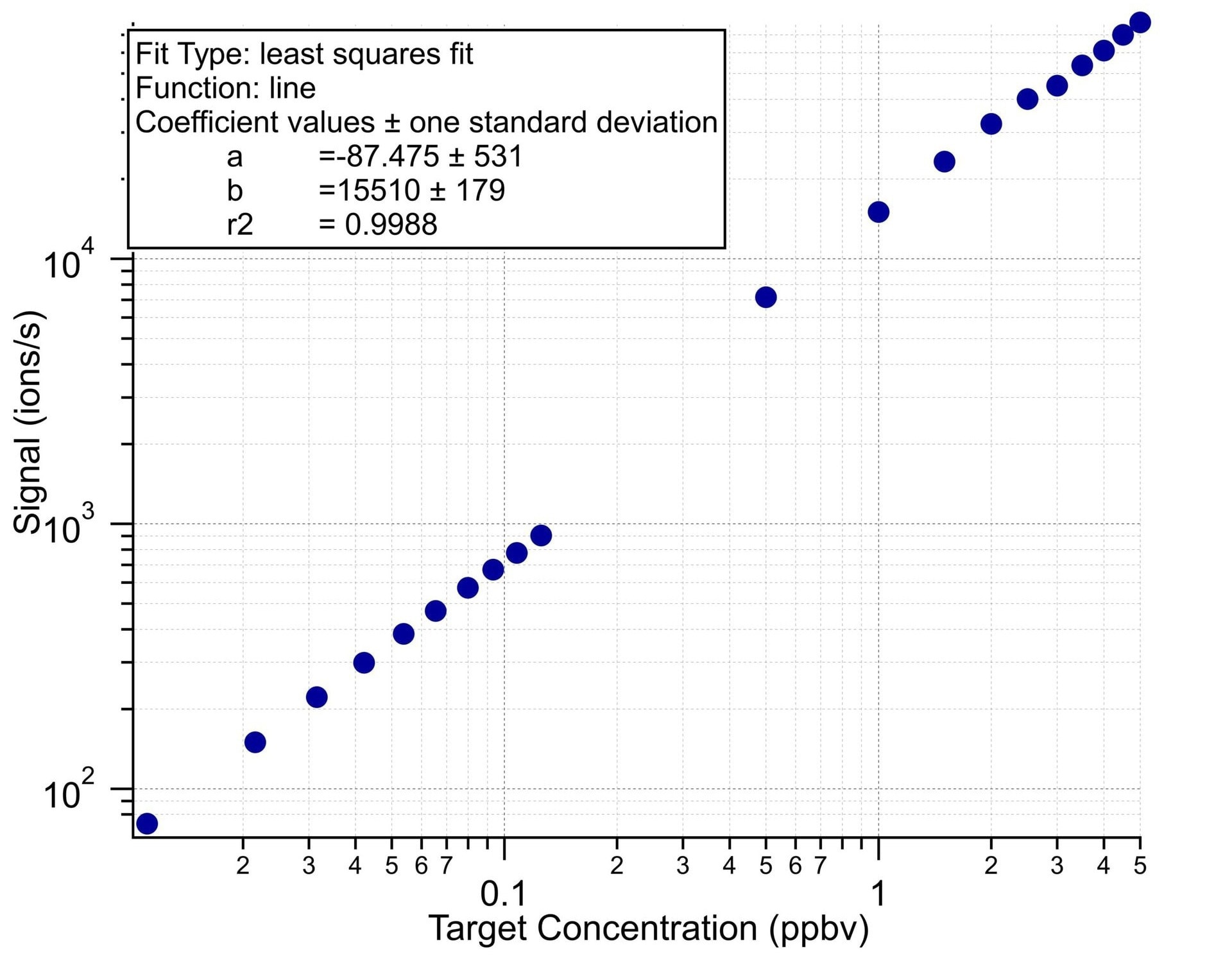

ClearFab AMC Monitors offer precise detection of single-digit, part-per-trillion concentrations in real-time, allowing bigger contamination control and detection than traditional technologies. Select limits of detection (LODs) offered by the ABC configuration are presented in Table 1, while coverage linearity is shown in Figures 3 and 4.

Table 1. Typical LODs for relevant semiconductor manufacturing compounds with a ClearFab AMC Monitor configured for the monitoring of acids (corrosives), bases, and condensables. Source: TOFWERK

| Compound Name |

CAS |

Molecule |

2s LOD (ppbv) |

1min LOD (ppbv) |

| Propylene glycol methyl ether acetate (PGMEA) |

108-65-6 |

C6H12O3 |

0.0065 |

0.0012 |

| Propylene glycol methyl ether (PGME) |

107-98-2 |

C4H10O2 |

0.052 |

0.0094 |

| Methyl Ethyl Ketone (MEK) |

78-93-3 |

C4H8O |

0.421 |

0.075 |

| Ethyl Acetate (EA) |

141-78-6 |

C4H8O2 |

0.104 |

0.019 |

| Cyclopentane |

287-92-3 |

C5H10 |

0.132 |

0.023 |

| Acetone |

67-64-1 |

C3H6O |

0.002 |

0.0009 |

| Toluene |

108-88-3 |

C7H8 |

0.012 |

0.003 |

| Ammonia |

7664-41-7 |

NH3 |

0.408 |

0.072 |

| Hydrogen fluoride |

7664-39-3 |

HF |

0.011 |

0.0002 |

| Hydrochloric acid |

132228-87-6 |

HCl |

0.526 |

0.095 |

| Nitric acid |

7697-37-2 |

HNO3 |

0.0072 |

0.0013 |

| Chlorine |

7782-50-5 |

Cl2 |

0.001 |

0.0002 |

Figure 3. Linear range of coverage for toluene. Image Credit: TOFWERK

Figure 4. To demonstrate reproducibility, accuracy, and time response, three sequences of increasing concentrations of MEK, PGME, and Toluene are presented. The left axis shows the measured signal while the right axis shows the measured concentration. The compounds were measured after dilution from a calibration cylinder with a total of 12 compounds, making an overall VOC concentration of ~1200 ppb. Image Credit: TOFWERK

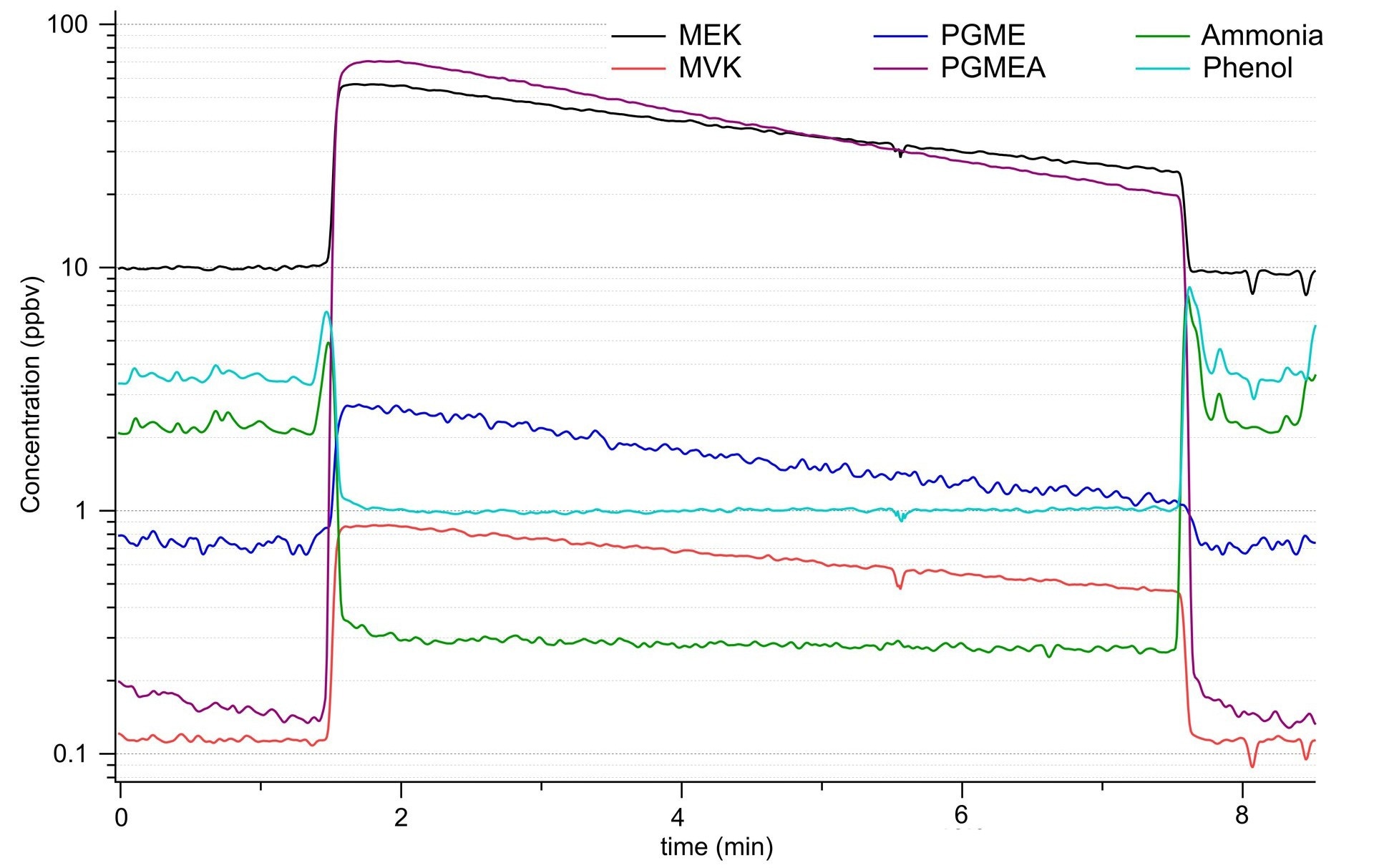

ClearFab AMC Monitors have been assessed for various fab applications, such as cleanroom monitoring, material off-gassing, leak detection, and FOUP quality control.

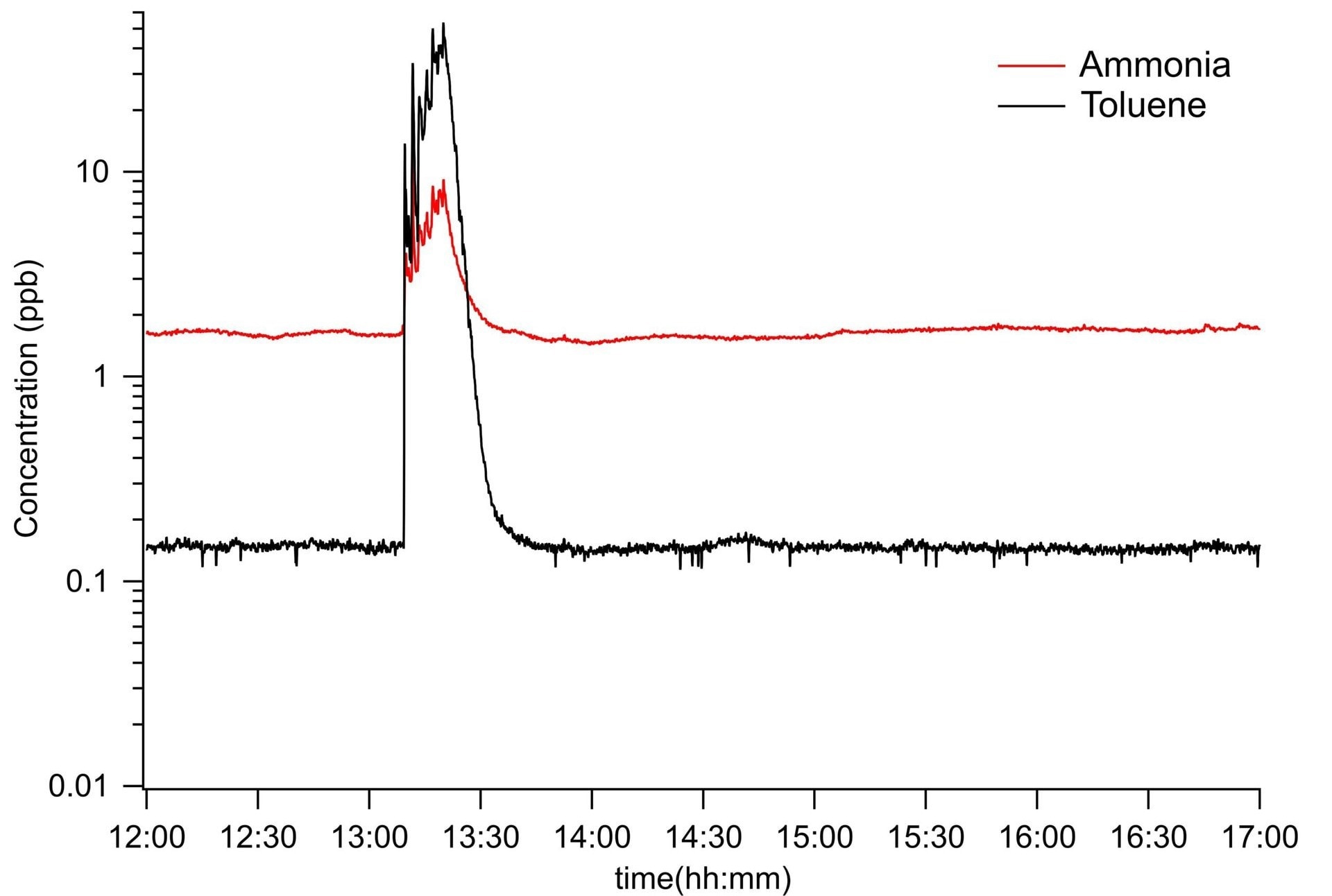

Figure 5 shows a cleanroom event where transient leaks of ammonia and toluene were detected. Figure 6 presents process off-gassing measurements for an ISO 5 microtechnology assessment.

Figure 5. Ammonia and toluene leak detected in an ISO 5 fine chemistry cleanroom. Image Credit: TOFWERK

Figure 6. Off-gassing of material in an ISO 5 microtechnology cleanroom. Material was purged with CDA and measured directly by the Vocus ABC Monitor. Each time series shows simultaneous compound measurements with 3 different ionization chemistries for comprehensive AMC coverage. Image Credit: TOFWERK

Conclusion

ClearFab AMC Monitors depict considerable progress in contamination control and monitoring, providing concurrent, quick, and sensitive detection of molecular classes that affect production efficiency and quality.

Performing complete measurement cycles below two seconds, and outstanding time response, ClearFab AMC Monitors offer a solution to contamination difficulties experienced across semiconductor fabrication processes and surroundings.

This information has been sourced, reviewed and adapted from materials provided by TOFWERK.

For more information on this source, please visit TOFWERK.