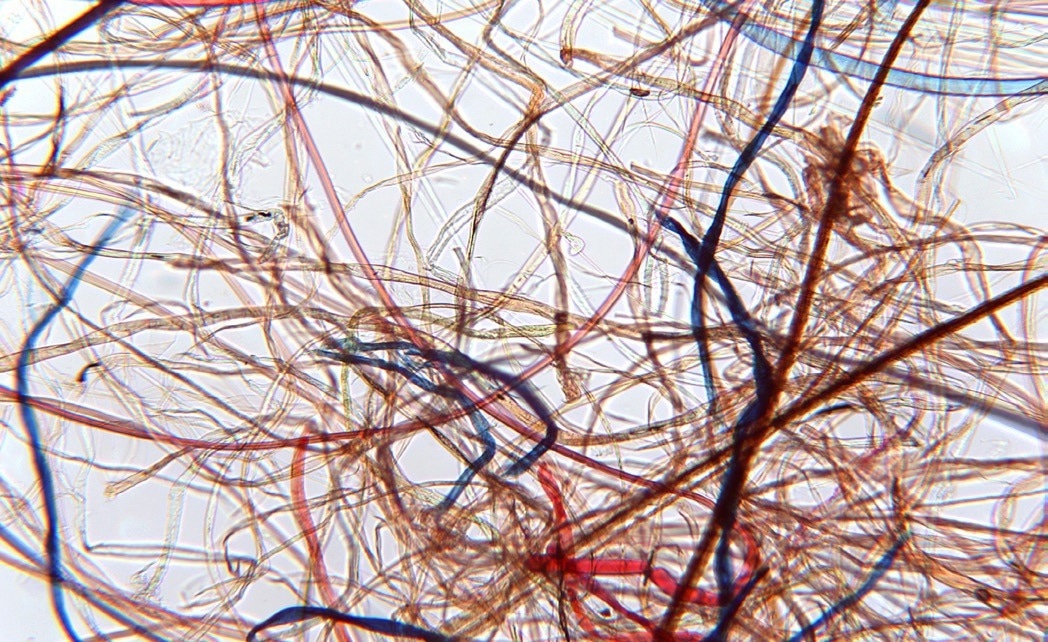

The focus of this article is on the analysis of fibers within a size range of 800 nm to 22 microns, as well as those with surface treatments, utilizing the mIRage+R, IR+Raman microscope. This is made possible through Optical-Photothermal Infrared (O-PTIR) spectroscopy, a pioneering sub-micron IR technique.

Image Credit: Photothermal Spectroscopy Corp

All fibers were analyzed directly without additional modification or sampling accessories. The O-PTIR spectra resemble transmission-like IR spectra in non-contact (far-field) mode. Through spatially resolved (micron) spectra, it is possible to identify the distribution of surface treatment on micron-sized fibers without dispersive or scattering artefacts.

The application of mIRage is extended to the analysis of a single nanofiber of 800 nm, completing the possibility of analyzing a full range of fibers for various fields such as forensics, textiles, filtration, medical scaffolds, art conservation, microplastics, and intellectual property protection.

The detection mechanism used in this application note offers several advantages:

- It provides sub-micron IR spatial resolution, which is a significant improvement over traditional FTIR/QCL Microscopy, with a ~20x improvement.

- Non-contact, reflection (far-field) mode measurements are used, resulting in FTIR transmission-like spectral quality.

- The O-PTIR method is insensitive to fluorescence, enabling the analysis of colored specimens.

- The possibility of an upgrade to include sub-micron simultaneous IR+Raman is available, providing the ability to obtain IR and Raman spectra from the same spot at the same time with the same spatial resolution.

Figure 1. The mIRage O-PTIR instrument. Image Credit: Photothermal Spectroscopy Corp., Santa Barbara, CA

Introduction

The identification and characterization of fibers often involve collecting infrared spectra using an FTIR microscope and comparing the spectra with commercial or custom IR databases.

The dimensions of fibrous filaments can vary greatly, from sub-micron to many tens of microns in diameter, which covers approximately the wavelength range of the infrared light used to measure the fibers. In this zone, infrared light may be dispersed and distributed, resulting in baseline deviations and tilts, which makes it difficult to employ reflection mode FTIR on fibers.1,2

Potential solutions, such as flattening the fiber with roller knives3 or using a micro-ATR accessory, can damage the fibers and modify their molecular orientation, compromising the accurate characterization of trace samples.

Forensic applications, in particular, are vulnerable due to the limited availability of evidence, and these limitations are equally applicable to emerging QCL IR microscopic technologies. To date, these issues have placed restrictions on the effectiveness of IR microscopy for fiber analysis.

Optical Photothermal Infrared (O-PTIR) eliminates these restrictions. O-PTIR induces a targeted modulated photo-thermal effect by illuminating the specimen with IR light from a pulsed and highly tunable QCL.

Instead of depending on the lengthy IR wavelengths, a 532 nm probing laser is co-localized with the IR light to detect the effect and determine the spatial resolution. This efficiently overcomes the diffraction limit of conventional FTIR/QCL microscopy.

Experiment

Kimble provided an eight-factor multi-fabric test specimen. Without any extra sample processing, a tiny part of the fabric was cut from the package and inserted straight into the test chamber of the mIRage+R Infrared and Raman Microscope, as illustrated in Figure 1.

Results

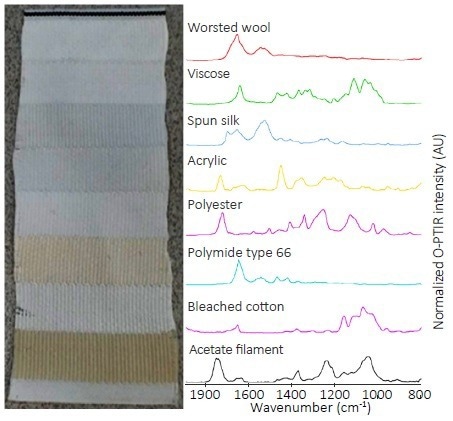

The O-PTIR spectrum acquisition of the eight-factor multi-fiber benchmark testing material was accomplished, leading to the collection of traditional IR spectra, all in reflection mode.

This test material's individual fiber sizes vary from 8 to 22 micrometers. Using these spectra, as seen in Figure 2, each layer can be identified using industrial IR databases, such as KnowItAll® from Wiley.

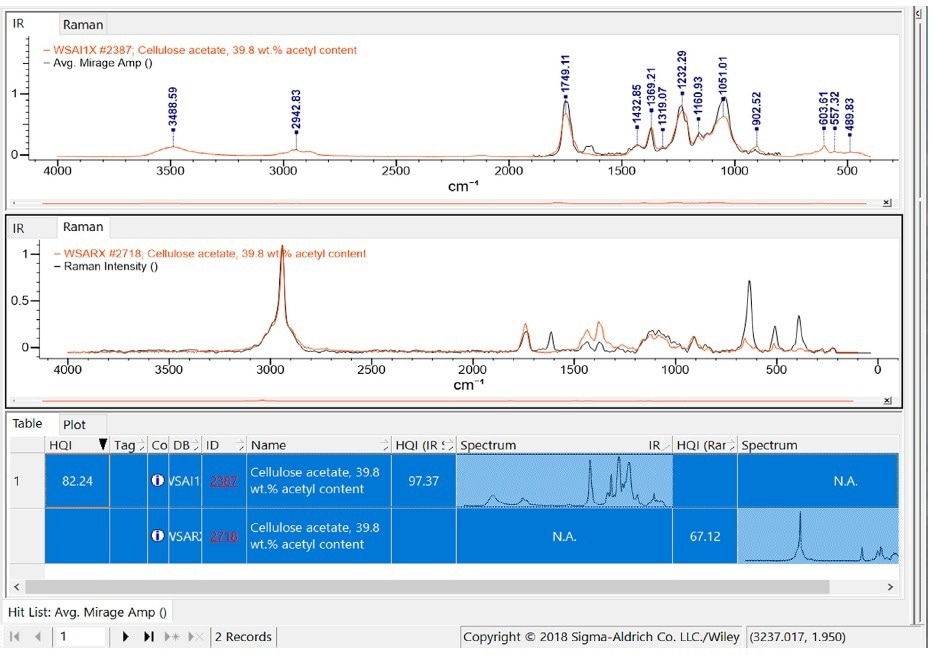

The simultaneous IR+Raman feature of the mIRage+R microscope transforms the identification of unknowns into a highly definitive process. As demonstrated in Figure 3, when O-PTIR and Raman data are examined against a commercially accessible infrared and Raman database, there is only one plausible result, the acetylated variant of cellulose.

Using concurrent submicron IR+Raman data from the same place, at the exact moment, with the same resolution could be seen as a complimentary and confirmatory approach.

Figure 2. O-PTIR spectra of single fibers in each of the eight layers of fabrics within the standard multi-fabric sample. Image Credit: Photothermal Spectroscopy Corp

Figure 3. Wiley KnowItAll simultaneous search list of both the IR and Raman spectra, reflecting cellulose acetate as the only probable search result. Image Credit: Photothermal Spectroscopy Corp

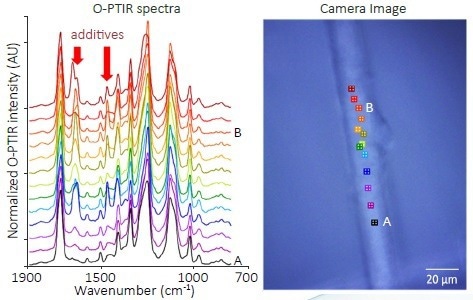

Figure 4. O-PTIR spectra collected along the length of a free-standing fiber in a piece of polyester fabric. Image Credit: Photothermal Spectroscopy Corp

The fundamental value of the mIRage-R microscope resides in its capacity to give spatially resolved conventional IR spectra much below the diffraction limit of infrared wavelengths, with no sample preparation required regardless of the fiber diameter.

The mIRage+R spectra are spatially resolved to produce a relative concentration profile over the length of the fiber, as illustrated in Figure 4. Spectrum A is a virtually pure IR spectrum from polyester fiber, while Spectrum B has a significant additive concentration.

The primary amide absorption at 1650 cm-1 and the CH2 scissoring band at 1456 cm-1 increase along the fiber length. These absorptions are consistent with primary alkylamides additives that are present usually in less than 1% w/w for the processing of polyester as it is being dry spun.4

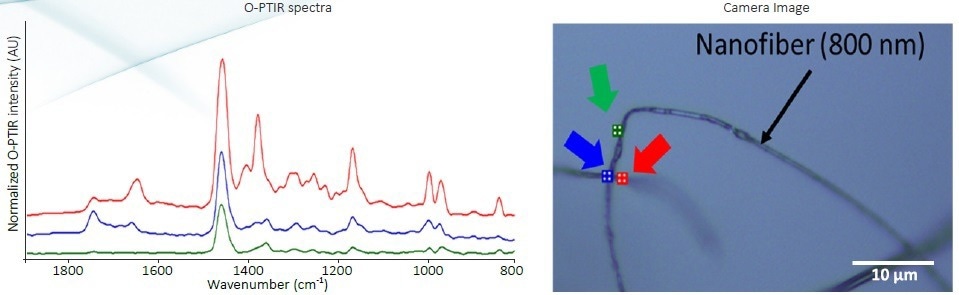

Figure 5. O-PTIR spectra of PP-based nanofibers with 800 nm diameter. Image Credit: Photothermal Spectroscopy Corp

The mIRage+R can even collect high-quality spectra on nanofibers with a diameter similar to the spatial resolution of the instrument. Without the need for flattening the fibers physically, the mIRage+R can still collect IR absorption spectra of such fibers in free air that show no dispersive artifacts without making physical contact, as shown in Figure 5, and without the risk of cross-contamination, which is a potential issue with micro-ATR.

The stearic acid additives from polypropylene nanofibers can be seen along with the polypropylene base material. The 1705 cm-1 and 1650 cm-1 correspond to the dimer and the dissociated carboxylic acids. This material is known for controlling the diameter of the nanofiber as it is being electrospun.5

Conclusion

The mIRage+R Infrared and Raman Microscope can collect O-PTIR and Raman spectra in a single click on fibers ranging from 8-22 microns and 800 nm in diameter. The resulting spectra are transmission FTIR-like, showing no dispersive artifacts, making it easy to identify unknown fibers using commercial infrared and Raman databases.

Using simultaneous IR and Raman data from the mIRage+R microscope allows for a comprehensive spectroscopic characterization that guarantees precise identification of unknown fibers and other materials.

References

- Bassan, P. (2009) Resonant Mie scattering in infrared spectroscopy of biological materials – understanding the ‘dispersion artefact.’ Analyst, 134, p. 1586.

- Bassan, P. (2009) Reflection contributions to the dispersion artefact in FTIR spectra of single biological cells. Analyst, 134, p. 1171.

- Grieve, M. C. (1995) Another look at the classification of acrylic fibres, using FTIR microscopy. Science & Justice, 35, p. 179.

- Reedy, A. L. Spinnable compositions comprising a fiber forming polyamide, a fiber forming polyester and a spinning aid. US Patent 3,516,956.

- Chen, Z. (2014) Effect of polar additives on melt electrospinning of non-polar polypropylene. J. Serb. Chem. Soc., 79, p. 587

This information has been sourced, reviewed and adapted from materials provided by Photothermal Spectroscopy Corp.

For more information on this source, please visit Photothermal Spectroscopy Corp.