Technical ceramics are used in many applications where traditional materials such as steel or plastic are ineffective or unsuitable. For many of these applications, extreme hardness, wear resistance, and high-temperature strength are necessary. Aerospace and harsh industrial settings could be among them.

For medical, semiconductor, and instrumentation applications, components of electrical or thermal insulation and resistance to many types of chemical attacks could be crucial. Heat conductivity is explored in this experiment.

Thermal Conductivity Experiment - with Background Music

Video Credit: INSACO Inc.-Machining of Hard Materials

Silicon Carbide. Image Credit: INSACO Inc.-Machining of Hard Materials

INSACO has created specialized machinery and machining methods to create technical ceramic parts with fine tolerances that satisfy the demanding requirements of today’s design engineers.

Since 1947, INASCO has been actively engaged in the production and polishing of precision components, along with helping designers choose the best materials. These discussions typically touch on the production methods that preserve cost control while simultaneously delivering constant performance.

Not all technical ceramics are extremely hard. While some are delicate, others are highly impact-resistant. There are significant differences in all material attributes across various material options. Some ceramics, such as sapphire, can make completely transparent windows or lenses that are also highly durable and resistant to wear.

The thermal conductivity of various materials also varies considerably. For example, specific grades of silicon carbide may transmit heat and certain metals, such as aluminum.

INSACO developed a creative “Science Experiment” to visually illustrate this feature because it frequently surprises many designers that one of the toughest technical ceramics can transfer heat well.

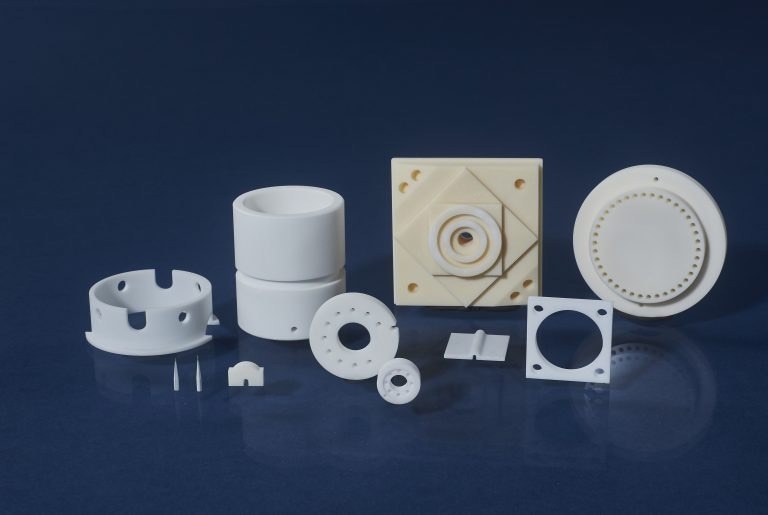

Zirconia. Image Credit: INSACO Inc.-Machining of Hard Materials

Alumina. Image Credit: INSACO Inc.-Machining of Hard Materials

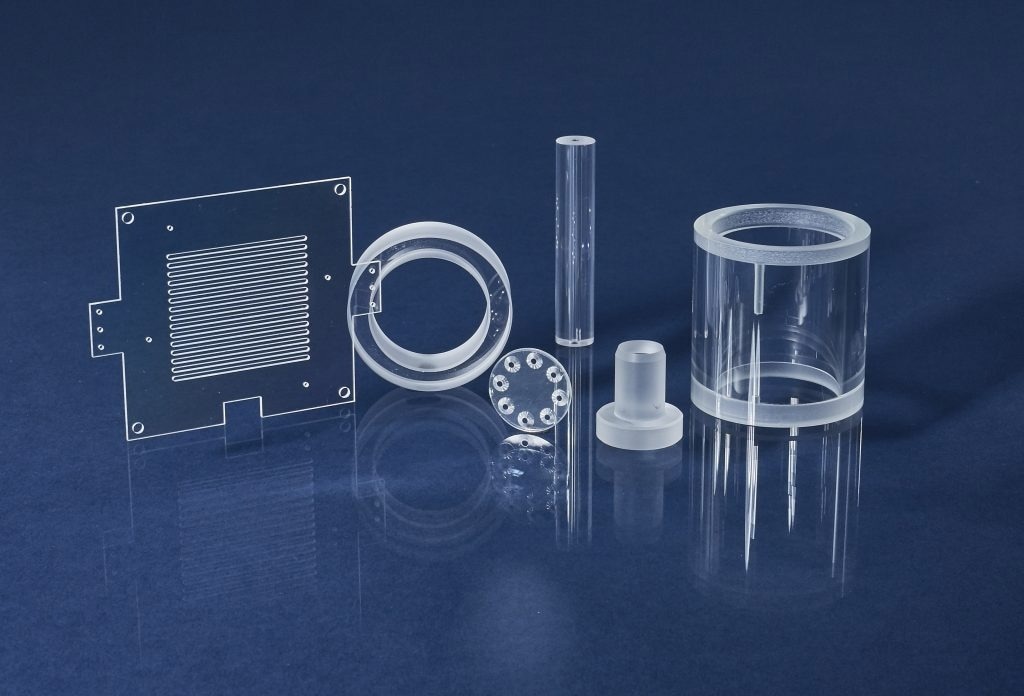

Quartz. Image Credit: INSACO Inc.-Machining of Hard Materials

Simple rods were fabricated using a variety of technical ceramics and several representative metals, such as steel and aluminum. Then, to determine which end would melt the ice the quickest, they were all uniformly exposed to intense heat on one end.

The CVD silicon carbide melts ice the fastest among the group, with plain aluminum metal coming in second. Aluminum nitride follows. A rod made of low-carbon steel was then used as a comparison.

Although sapphire and alumina are the same substance, the single-crystal form of aluminum oxide has a somewhat higher thermal conductivity than the sintered form. Quartz and Zirconia were the two slowest materials in the group.

This information has been sourced, reviewed and adapted from materials provided by INSACO Inc. - Machining of Hard Materials.

For more information on this source, please visit INSACO Inc. - Machining of Hard Materials.