In this interview, AZoM talks to Annika Völp, an applications specialist at Thermo Fisher Scientific, about the role of rotational rheology in battery manufacturing and research. The interview also touches upon the different types of rheometers and rheology data interpretation.

Please could you introduce yourself and tell us a bit about rheology?

My name is Annika Völp. I am an application specialist at Thermo Fisher Scientific.

Rheology is the science of the flow and deformation of matter. Different techniques and instruments are available to study the flow properties of various materials under different conditions. A rotational rheometer is a versatile device for rheological investigations of various samples.

Image credit: Thermo Fisher Scientific

Where is rotational rheology used?

Rotational rheometers are used in many industries for quality control of incoming raw materials, intermediates, and final products and in developing new formulations. Information about the rheological behavior can help ensure that a product performs well in a given application or can be processed in a certain way.

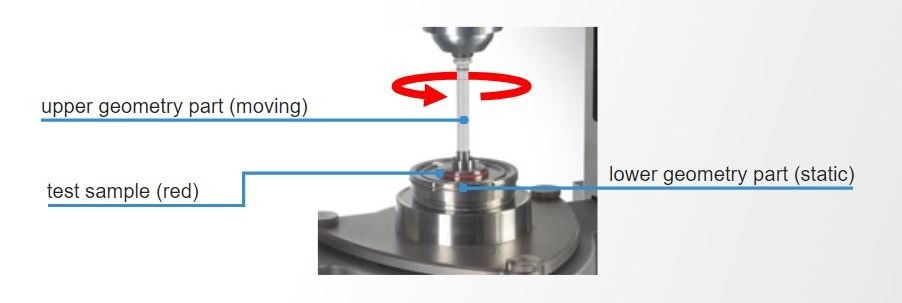

How does a rotational rheometer work?

A test sample is filled into a measuring geometry, and the rheometer applies defined shear stresses or shear deformation. The response of the sample causes mechanical excitation to be detected and this is used to calculate rheological parameters.

A modern rotational rheometer can apply shear stresses or shear strains through continuous rotational motion and sinusoidal oscillation. Measurements in oscillation mode are usually used to obtain detailed information about the viscoelastic properties of a material. In a rotational rheometer, most measurements are performed under well-defined conditions, including precise temperature control and consistent flow conditions throughout the test sample volume.

Rotational Rheometer. Image credit: Thermo Fisher Scientific

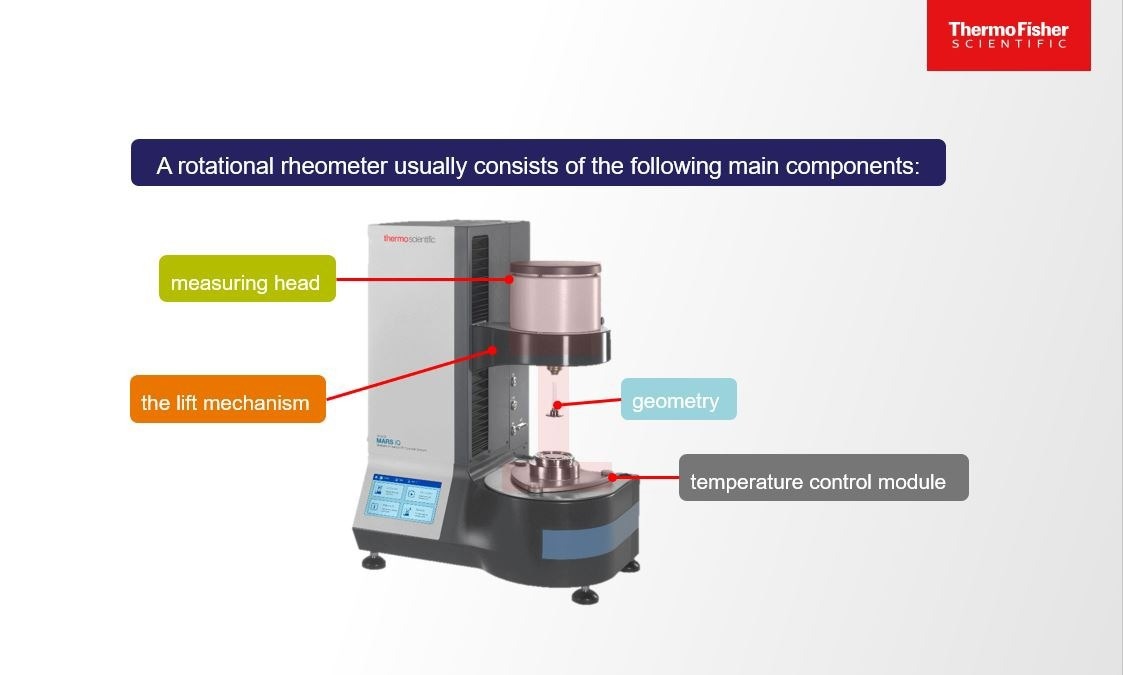

What are the components of a rotational rheometer?

A rotational rheometer includes a measuring head, which applies the shear stress or shear deformation and measures the sample's response, and an accurate lift mechanism, which moves the measuring head and the upper part of the measuring geometry into the correct measuring position.

Components of a rotational rheometer. Image credit: Thermo Fisher Scientific

It also has measuring geometry that holds the sample and transfers the torque or motion generated by the motor to the sample, as well as a temperature control module that provides defined temperature conditions and supports the lower part of the geometry.

Are there any other instruments commonly used for measuring flow?

A rotational spindle viscometer frequently measures liquid samples' flow properties. With this device, the flow of a sample is initiated by a rotating fixture, the spindle, and a viscosity value is calculated from the ratio of torque and rotational speed. However, compared to a rotational rheometer, a simple spindle viscometer is somewhat limited and has several shortcomings.

A spindle viscometer usually measures viscosities at a single rotational speed and a single-point measurement. In these cases, it will not generate a complete flow and viscosity curve, and will not reveal any complex non-Newtonian flow behavior.

The typical single rotational speed of a spindle viscometer. Image credit: Thermo Fisher Scientific

The spindle viscometer does not generate a well-defined and uniform flow field throughout the sample volume. The results must be considered relative or apparent viscosity data instead of absolute values.

On its standard setup, a spindle viscometer has no temperature control. Measurements are usually performed at room temperature in a lab beaker or the original sample container. Finally, a spindle viscometer cannot be used to investigate and quantify elastic properties of a material. Only a real rotational rheometer is capable of all of the above.

Could you tell us more about the application of rotational rheometers in battery manufacturing?

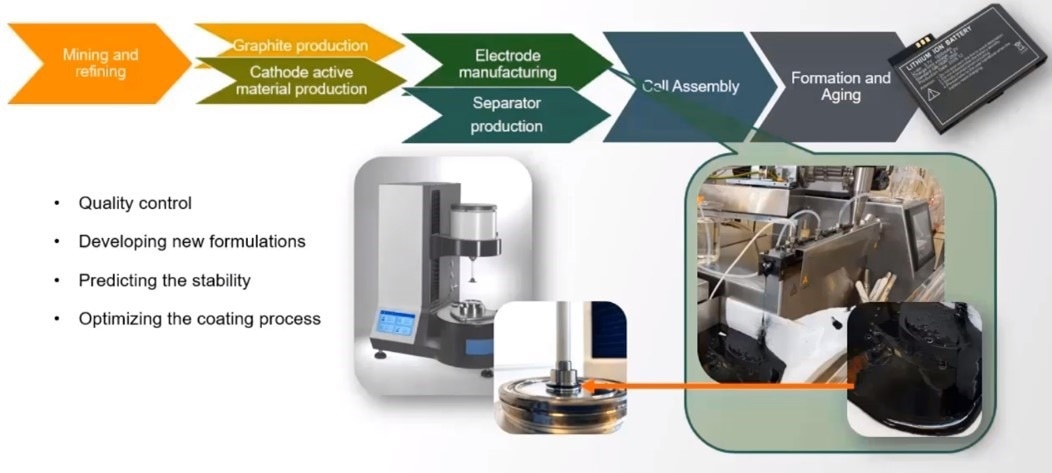

The manufacturing process of lithium-ion batteries involves the following steps. The metal oxides and graphite are mined and refined. Cell manufacturers then mix anodes and cathode slurries from the material. Subsequently, the slurries are each coated onto the collective foils to form electrodes.

After this, separators are purchased from one of the few market-leading suppliers, stacked with the electrodes, and further processed into battery cells. Finally, the cells are assembled into a battery, and pre-conditioned for several days by charge/discharge cycles called formation and aging. Rotational rheometers are used to measure the flow properties of these slurries for electrode manufacturing.

How do rotational rheometers help the slurry and electrode manufacturing process?

Various aspects of slurry production and processing involve rheometers, including quality control to ensure that the produced slurries always show the same flow properties. To perform well in the electrode production process, the rheological behavior of a slurry needs to be within a certain range. Using rheological measurements in the development process of new formulations avoids time-consuming and expensive trial series in the actual production or pilot scale setup.

After mixing and during storage, electrode slurries can show undesired behavior such as acclimation of particles or the sedimentation of larger particle clusters. This is why battery slurries may require further agitation during storage to avoid quality issues with the final product. Rheological data can help predict electrode slurries' stability and, therefore, the need for continuous agitation during storage.

To deliver the desired final battery properties, a slurry must perform well when coated onto a current collector foil. When knowing the rheological properties of the electrode slurries, adjustments to the settings of the coating process can be carried out to achieve the best possible coating quality.

Application of rheometers in battery manufacturing. Image credit: Thermo Fisher Scientific

Could you please describe the typical production cycle of an electrode slurry?

The raw components must be properly mixed to obtain a slurry with homogeneously dispersed ingredients. In a batch process, the slurry is stored until it is moved to the actual coating process. Here, additional stirring may be required to avoid undesired phase separation effects.

Finally, the slurry is printed onto the current collector foil, usually in a blade or a slit-die coating process. During all these steps, rheological measurements provide information about proper mixing with a homogeneous distribution of active components, the storage behavior, and the stability of the electrode slurries.

Could you tell us more about the behavior of electrode slurries?

Battery slurries are exposed to a wide range of shear conditions in the coating process. Proper mixing and homogeneous coating process are essential to obtain batteries with a high capacity in a high number of charging cycles.

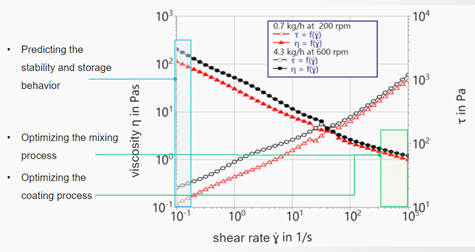

Electrode slurries usually show a so-called shear thinning behavior, which means the viscosity decreases from high values at low shear rates to lower values when the shear rates increase.

This is a desired behavior for many complex fluids, including electrode slurries, because high viscosities, at low shear rates or at rest, slow down the sedimentation or aggregation effect significantly, leading to a better shelf life and less need for any agitation during storage.

However, high shear rates occur when the material is applied onto the current collective foil via slit-die coating. To achieve a quick and homogeneous coating process with a constant layer thickness, the sample viscosity must be within a specific range, and neither be too high nor too low.

Complete viscosity curves spanning from low to high shear rates are, therefore, extremely useful to predict various essential aspects in the process cycle of an electrode slurry. Low shear rates can predict stability and storage behavior. Medium to high shear rates can help to optimize the mixing and coating process.

Measuring the viscosity in continuous rotational deformation over a broad range of shear rates reveals the dispersion quality of slurries, their processability, and stability. Image credit: Thermo Fisher Scientific

How are oscillatory measurement techniques used in the dry electrode manufacturing process?

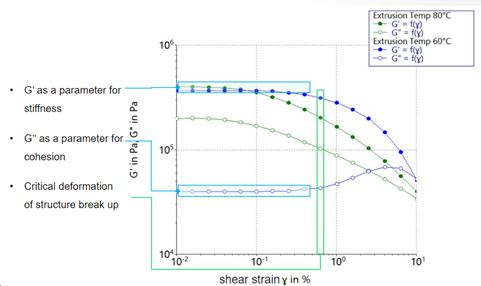

An approach to reduce energy-consumptive drying of the electrode coating is to produce a freestanding dry electrode. For stiffer, more rubber-like electrode materials containing significantly less solvent, oscillatory measurement techniques can reveal the visco-elastic properties. This information is helpful for the development of new formulations and for predicting how the material behaves during the coating process.

A typical measurement in oscillation mode is the so-called amplitude sweep, where the material is exposed to a series of stepwise increasing defamation amplitudes at a fixed frequency. This experiment provides information about the general structure of a material, such as whether it is more liquid or solid-like, as well as the firmness and stability of its structure.

The information that can be extracted from this experiment includes the storage modulus, G' in the linear visco-elastic range, which is a constant value at low strain values as a parameter for stiffness. The loss modulus, G'' in the linear visco-elastic range is a parameter for cohesion. Critical deformation indicates structure breakup and is a parameter for the stability of the sample.

Characterization of shear stress in sinusoidal oscillatory deformation reveals visco-elastic parameters defining. Image credit: Thermo Fisher Scientific

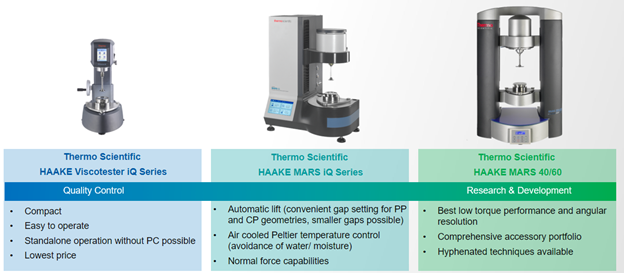

What instruments does Thermo Fisher Scientific offer for rheology?

Thermo Fisher Scientific offers a whole range of different Rotational Rheometers, from compact quality control instruments to high-end rheometers for research and development. These instruments differ in the width of the available measuring range with regard to torque and rotational speed, as well as in the available accessory portfolio.

Which instrument is right for your application depends on the type of samples and the kind of experiments you wish to conduct. All our rheometers can be equipped with temperature control units, generate absolute viscosity data, and can perform shear rate sweep tests to produce complete flow and viscosity curves.

Is there anything further you wish to add?

In summary, a rotational rheometer is a device to measure viscosity as a function of shear rate and temperature, as well as for oscillatory characterization of visco-elastic material behavior, while a spindle viscometer can provide only an apparent viscosity value at a single shear rate.

Awareness of the rheology of battery paste is essential for quality control and saves time and cost when developing new formulations, as it is useful to predict the storage stability of dispersions and their behavior in the electrode coating process.

To learn more on extrusion or rheometry for battery applications, visit Thermo Fisher Scientific’s advanced battery technology website for application notes, videos, and webinars.

Flexible and robust rheometers (Viscotester iQ, MARS iQ, and MARS 40/60) for Quality Control up to Research and Development. Image credit: Thermo Fisher Scientific

About Dr. Völp

Annika Völp, Dr.-Ing is an Application Specialist with Thermo Fisher Scientific focusing on the extrusion of polymers and twin-screw compounding of battery materials. Annika received her Dr. -Ing from the Institute for Mechanical Engineering and Mechanics, Karlsruhe Institute of Technology (KIT), Karlsruhe, Germany. During her Ph.D. studies, she investigated the structure and rheology of foams. Annika also has a degree in Bioengineering from KIT.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Materials & Structural Analysis.

For more information on this source, please visit Thermo Fisher Scientific – Materials & Structural Analysis.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.