At JEC World 2023, AZoM caught up with 5M to discuss their rapid growth and exciting plans for the future.

Please can you introduce yourself and your professional background?

I’m Tomáš Turek, a key account manager at 5M. My main focus is on the bus companies like IVECO, Wrightbus, VDL and others.

We are supporting, I believe, almost every company in Europe which is producing buses, but we also have a big influence on different markets like trains, trams, and aerospace.

What products and technologies does 5M offer?

Our main focus is on pultrusion production. This includes glass fiber, carbon fibers, or others with some resin, polyurethane, or polyester - it really depends on the customer’s request. We also do sandwich panels with various skins and cores. For the aviation industry, for example, we use various types of materials like Nomex sandwich panels or others. Our last focus is on the resin market.

Could you give me some examples of the industrial sectors your materials are used in?

Our biggest sector is aviation, followed by trains and trams. The third biggest sector for us is the bus producers. We see a strong potential in this type of industry in the next few years because the global electrification of buses is strong, and we are offering light materials, which are helping to increase the driving range. Over the last year, we've been in a lot of contact with UK providers for buses, for example, but also with big global players in the European continent.

Another interesting sector for us is space. We have our own research and development team. We are mainly supporting the European Space Agency, but we also have some experience with NASA.

What kinds of materials would you supply to the space sector?

We provide the sandwich panels or some special resins directly developed and produced for an aerospace segment. We have already signed six contracts with commercial customers.

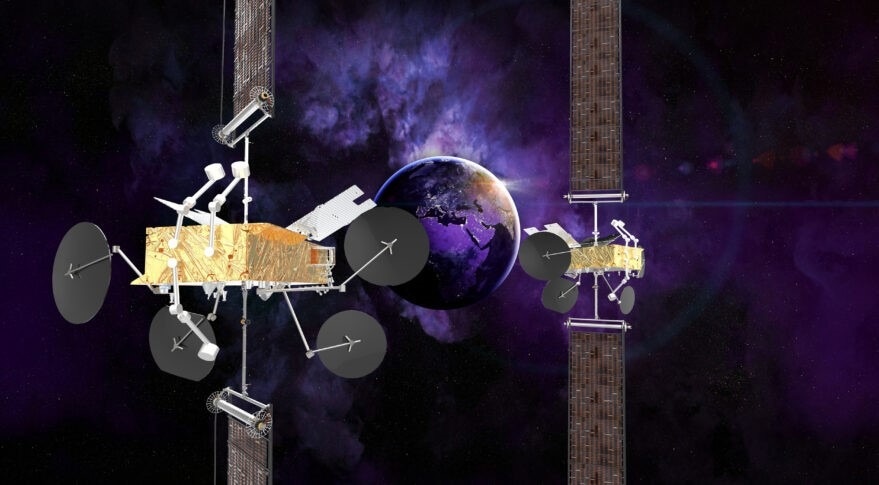

Now we are the only provider with our partners for European customers who demand flexible solar panels for satellites, which are really important because they reduce the space you need in a rocket. It is for us something new and exciting.

Image Credit: 5M

Why should people pay attention to composites? Why are they so important to these industries?

Composites as a sector are the future for every public transportation thanks to their low weight and great mechanical properties. For example, in the bus transport sector, there is globally a shift from diesel and petrol to electrification and hydrogen. With this comes the requirement for lightweighting. This is one of the biggest advantages of composites currently in the bus sector.

How important is sustainability to 5M?

We are always trying to be more eco-friendly. Our molds, for example, are more expensive in the interest of them being more sustainable. What is difficult is that one of the advantages of our products is that they are very durable, which makes recycling hard. One idea is to recycle our waste composites into highways so that they do not end up as waste.

Image Credit: 5M

What does research and development look like at 5M?

We have our own research and development team, which is around 60 people now and constantly growing. They are also working a lot on sustainability - how to reuse the resin, for example. The quality team is always pushing to find the fastest, safest, cheapest, and most easily-recyclable material.

You exhibited this year at JEC World – The Leading International Composites Trade Show. Why do you think it is important for 5M to engage with this show?

You can see competitors, new technologies, and innovations in the composite industry. It's not only about pultrusion, or about the sandwich panels. It's about the wet lamination, for example, which we are not doing and want to do.

Image Credit: 5M

It’s great to see that we have had a revolution in our industry, where we are starting to replace aluminum or steel with composites. There is much more that we see that we want to incorporate into our processes.

For us, being here is mainly about visiting our current customers. The COVID situation two years ago limited us, but now we can hang out with these people, shake their hands, and say, "Yeah, let's go to dinner". This is very important to us as a business.

How does 5M plan to grow in the coming years?

We are growing year-on-year and constantly getting bigger. In the next few years, we see big potential in the space sector. There is a struggle to find skilled employees in this sector, which is something we are trying to tackle, but our products are very good, and once we overcome this hurdle, we will progress quickly. We are also expanding our warehouses and are looking to build another soon.

Do you have any exciting developments on the horizon?

Hydrogen solutions in transportation will be important in the coming years. We already see this in our current customers' buses. A lot of our current customers from this sector are now developing their own hydrogen bus, and we would like to be a part of this development with our composite materials.

More from JEC World 2023: How Huntsman Are Creating Market-Leading Adhesives and Composites

About Tomáš Turek

I am a Key account manager of company 5M s.r.o. Located in the Czech Republic. My main goal is to achieve success with composite materials and sandwich panels in the bus sector in the next few years, which seems to be a really important segment for composite producers in the future. As a company, 5M is one of the biggest European producers of composite materials, mainly producing for the Aerospace, Railway, and Bus sectors. We have more than 30 years of experience in the composite industries, and thanks to our production, you can also obtain pultruded composite products.

I am a Key account manager of company 5M s.r.o. Located in the Czech Republic. My main goal is to achieve success with composite materials and sandwich panels in the bus sector in the next few years, which seems to be a really important segment for composite producers in the future. As a company, 5M is one of the biggest European producers of composite materials, mainly producing for the Aerospace, Railway, and Bus sectors. We have more than 30 years of experience in the composite industries, and thanks to our production, you can also obtain pultruded composite products.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.