The characterization of polymers in the plastics industry relies heavily on the measurement of viscosity in polymer solutions. This fundamental tool is essential for assessing newly polymerized materials and post-consumer resins (PCRs).

Within the realm of plastics, the intrinsic viscosity, denoted as [η], has emerged as a crucial parameter for establishing correlations that predict processing behavior and physical properties. Professionals in the field identify targeted [η] values that result in optimal conditions for mixing, extruding, molding, and achieving desired final product performance.

Background

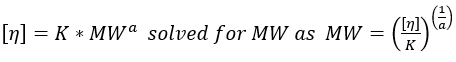

A polymer's molecular weight (MW) significantly influences the material's various properties. The intrinsic viscosity, [η], is directly related to the molecular weight through the Mark-Houwink-Sakurada equation:

Where, Κ is the prefactor for the MHS equation, and α is the exponent for the MHS equation.

This relation between MW and [η] allows the intrinsic viscosity to serve as a reliable indicator of the molecular weight. When a material property is known to vary with MW, it typically exhibits a similar trend with [η].

Fortunately, measuring [η] is a cost-effective and exact method, enabling rapid assessment. Consequently, utilizing [η] as a surrogate for MW has been embraced as a convenient and dependable approach in the design of plastics for specific applications.

For instance, within the PET industry, certain product categories are associated with specific ranges of [η] values, as outlined in Table 1.1

Table 1. Grades (categories) of PET for Common Applications. Source: Cannon Instrument Company

| PET Grade |

Intrinsic Viscosity [dL/g] |

| Fiber grade |

0.40—0.70 |

| Film grade |

0.70—1.00 |

| Bottle grade |

0.70—0.78 |

| Water and soft drink bottle grade |

0.78—0.85 |

| Carbonated drink bottles |

0.73—0.80* |

*However, in the last years, requirements have shifted towards higher values.2

Note: In Europe and tropical areas, required [η] > 0.80 dL/g.

Experimental

Study of rPET content in bottles

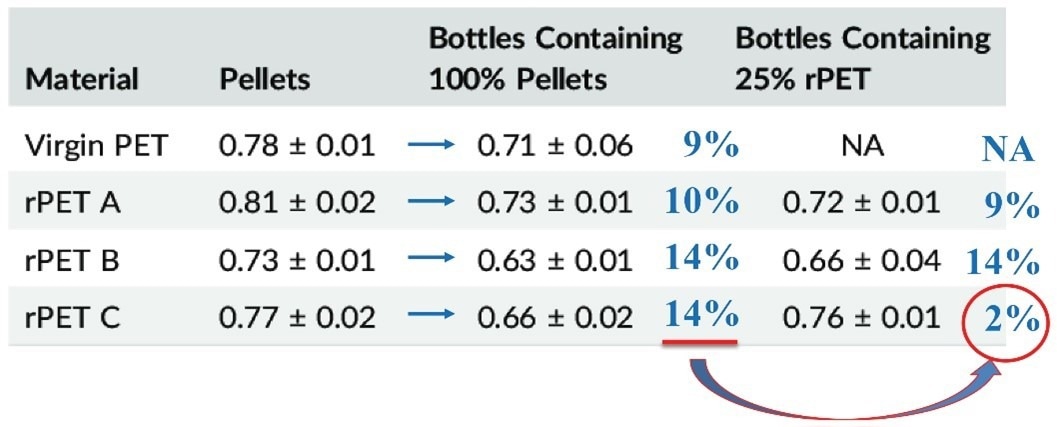

In a study3 conducted in 2020, a series of bottles were manufactured using virgin PET, three different types of rPET, and various combinations of these source materials. The study involved measuring the intrinsic viscosity of the original pellets, the bottles formed from these pellets, and 1:3 blends of rPET with virgin PET.

Table 2 presents the [η] values for the four types of pellets and their corresponding bottles. It also includes the [η] values for bottles molded from three different blends of rPET and virgin PET.

During the molding process, the bottles experienced a decrease in molecular weight, resulting in a drop in [η] ranging from 9% to 14% across the four PET types. Similarly, bottles molded from rPET A and rPET B blends also exhibited a comparable reduction in [η].

Interestingly, for rPET C, the decrease in [η] was only 2%, indicating significantly less degradation during the processing phase. This test matrix demonstrates the effectiveness of [η] measurements in distinguishing between different rPET blends and can aid in selecting suitable materials when incorporating rPET into formulations.

Table 2. IV Results for PET Types as Pellets and Bottles. Source: Cannon Instrument Company

Study of chain extenders for regulating changes in [η]

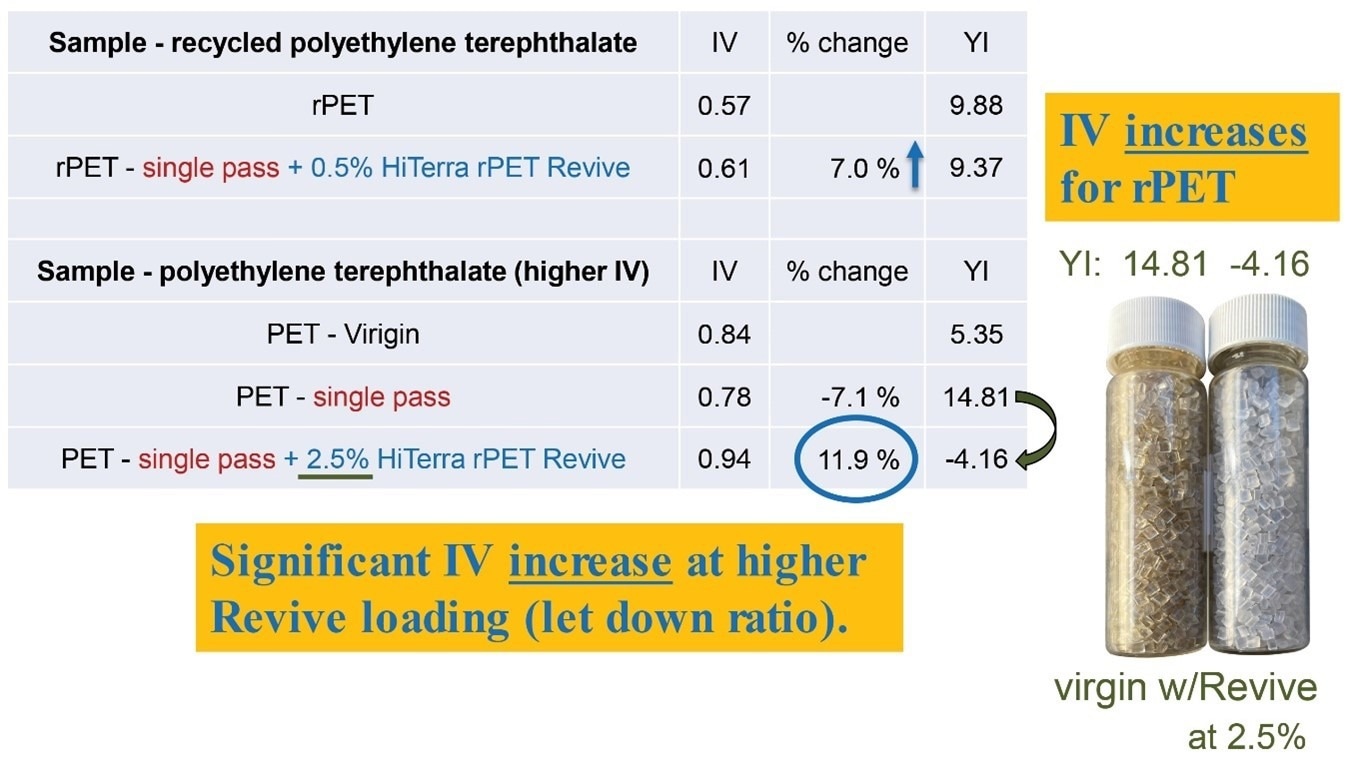

A study conducted by Techmer PM reveals the impact of its HiTerra rPET Revive chain extender in typical applications. The initial consideration focused on the improved stability of virgin PET, assessed by measuring [η] before and after a standard processing pass conducted consecutively.

Table 3 illustrates a decrease in [η] following the first pass and after the second pass. This comparison was repeated using virgin PET formulated with 0.5% HiTerra rPET Revive. In the presence of the chain extender, the degradation from the first pass decreased from 19% to 7.4% and further reduced from 25% to 14.7% for the second pass.

At a concentration of 0.5%, HiTerra rPET Revive stabilized the intrinsic viscosity by mitigating molecular weight degradation.

The same experimental design was applied to virgin PBT (polybytylene terephthalate). The results are presented in the lower section of Table 3. Surprisingly, with PBT, the usage of HiTerra rPET Revive increased measured [η], indicating evidence of chain extension for the PBT molecules.

Table 3. Processing Impact in the Presence of Chain Extender for PET and PBT.

Source Data: Techmer PM

![Study of chain extenders for regulating changes in [?]](https://www.azom.com/images/Article_Images/ImageForArticle_22774_16867274099042711.jpg)

Further measurements of [η] were conducted for rPET with and without HiTerra rPET Revive. These results are provided in Table 4. An important finding is the 7% increase in [η] after a single processing pass, in contrast to the 7.4% loss in [η] observed for virgin PET, and a 19% loss for unprotected virgin PET.

An additional test examined the impact of HiTerra rPET Revive on virgin PET with a higher intrinsic viscosity (larger molecular weight), with the loading (let down ratio) increased from 0.5% to 2.5%. The results can be found in the lower part of Table 4.

Comparing the results after one processing pass, virgin PET with the 2.5% chain extender exhibited an 11.9% increase in measured [η]. Notably, there was also a significant improvement in the yellow index, as depicted in the image embedded in Table 4.

Table 4. Chain Extender Influence on rPET and Virgin PET. Source Data: Techmer PM

Results and Discussion

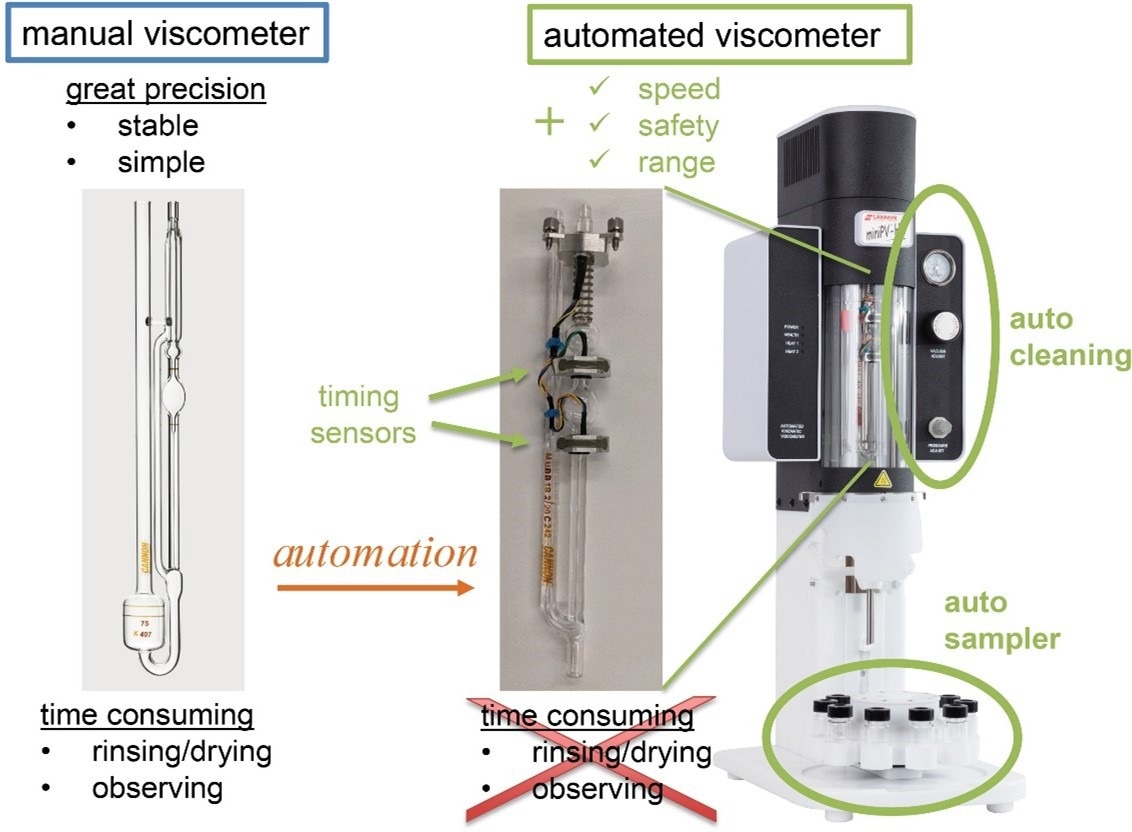

The automation incorporated into the miniPV® viscometer of Cannon Instrument Company® (refer to Figure 1) enables the realization of high precision in viscosity measurements of dilute polymer solutions. The advantages of automation over manual measurement procedures expedite studies like those described.

Using the miniPV's automation increases measurement throughput while maintaining stable flow conditions, simple operation, and high precision.

The automated viscometer ensures a clean and dry state after each measurement, preparing it for subsequent measurements in the autosampler carousel.

This high level of efficiency makes [η] measurements a feasible and preferred parameter for monitoring changes in polymer size and for conducting studies to optimize processing and product development.

Figure 1. Advantages of Viscometer Automation Found in the miniPV from Cannon Instrument Company. Image Credit: Cannon Instrument Company

Conclusions

The intrinsic viscosity, [η], of polymer solutions is a discerning tool for scrutinizing the effects of processing and identifying polymers suitable for targeted applications. This utility of [η] positions it in a central role in characterizing polymers, integrating them into workflows that embrace the circular economy by incorporating PCRs such as rPET.

References and Further Reading

- “The Importance of Controlling Intrinsic Viscosity in Extruded Pet.” ICPG, March 11, 2021. https://blog.icpg.co/the-importance-of-controlling-intrinsic-viscosity-in-extruded-pet.

- Awaja, F., and D. Pavel. “Recycling of PET.” European Polymer Journal 41, no. 7 (n.d.): 1453–77.

- Thoden van Velzen, Eggo Ulphard, Marieke T. Brouwer, Carina Stärker, and Frank Welle. “Effect of Recycled Content and Rpet Quality on the Properties of PET Bottles, Part II: Migration.” Packaging Technology and Science 33, no. 9 (2020): 359–71. https://doi.org/10.1002/pts.2528.

This information has been sourced, reviewed and adapted from materials provided by Cannon Instrument Company®.

For more information on this source, please visit Cannon Instrument Company®.